DTF Printing (Direct-to-Film) is a modern textile decoration method that uses specialized equipment to apply heat and pressure, securing vibrant colors and long-lasting designs on various fabrics. It offers endless design possibilities, streamlined production, quick turnaround times, and cost efficiency, making it ideal for designers, businesses, and individuals seeking high-quality custom apparel. Selecting the right materials (compatible film, ink, and fabric) is crucial for achieving superior quality. This guide covers each step of the DTF Printing process, from image preparation to printing, heat application, and curing stages. DTF Printing allows for intricate patterns, vibrant colors, and detailed images directly on fabric, suitable for fashion and personal expressions of art. Following best practices ensures optimal results, including selecting high-quality films, correct design preparation, precise cutting, troubleshooting tips, and adequate drying time.

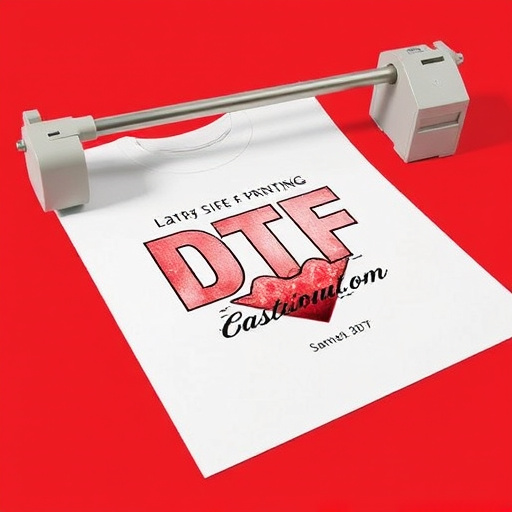

“Unleash your creativity with Direct-to-Film (DTF) printing, a game-changer in custom T-shirt design. This innovative technique allows for stunning, high-resolution prints directly on fabric, transforming ordinary tees into extraordinary works of art.

In this comprehensive guide, we’ll explore the benefits of DTF for creating unique garments. From understanding the process to choosing the right materials and creative tips, we’ll navigate you through every step, ensuring optimal results. Discover the endless possibilities of DTF Printing and elevate your T-shirt designs today.”

- Understanding Direct-to-Film (DTF) Printing: A Unique Approach to T-Shirt Decorating

- The Benefits of DTF for Custom T-Shirt Design

- Choosing the Right Materials: Essential for High-Quality Prints

- Step-by-Step Guide: From Image Preparation to Final Product

- Creative Possibilities: Designing Stunning Visuals for Your Tees

- Best Practices and Troubleshooting Tips for Optimal DTF Results

Understanding Direct-to-Film (DTF) Printing: A Unique Approach to T-Shirt Decorating

Direct-to-Film (DTF) Printing is a cutting-edge technique that has revolutionized the way we decorate t-shirts and other textiles. Unlike traditional printing methods, DTF skips the intermediate steps of printing on paper or fabric first, instead transferring ink directly onto the garment’s surface. This unique approach offers several advantages, making it a popular choice among designers, businesses, and individuals looking to create high-quality, durable designs.

The process involves specialized equipment that applies heat and pressure to bond the ink with the t-shirt fibers, ensuring vibrant colors and a long-lasting finish. DTF Printing allows for an array of design possibilities, from intricate details and fine lines to bold graphics and full-color images. Moreover, it is suitable for various fabric types, making it versatile enough for customizing everything from casual tees to promotional merchandise.

The Benefits of DTF for Custom T-Shirt Design

Direct-to-film (DTF) printing offers a revolutionary approach to custom t-shirt design, bringing numerous advantages over traditional methods. One of its key benefits is the ability to produce high-quality, vibrant prints with exceptional detail and color accuracy. This technology allows for direct application of designs onto various fabrics, ensuring a smooth and even finish without any visible signs of printing processes.

DTF also streamlines the design process, making it an efficient choice for small businesses and entrepreneurs. With its quick turnaround times and cost-effectiveness, DTF Printing enables easy customization of t-shirts, allowing designers to experiment with various styles, patterns, and images. This versatility makes it a favorite among those seeking unique, personalized apparel while maintaining a professional touch.

Choosing the Right Materials: Essential for High-Quality Prints

When it comes to DTF (Direct-to-Film) printing for t-shirt decoration, selecting the right materials is paramount to achieving high-quality prints. The process involves using specialized film that’s compatible with your printing equipment and ink. Opting for top-tier materials ensures precise color reproduction, vibrant hues, and a lasting finish on the fabric.

Choosing the appropriate substrate, or base material of the t-shirt, plays a crucial role as well. Different fabrics have varying properties affecting ink absorption and overall print quality. Cotton, for instance, is a popular choice due to its softness and ability to accept ink effectively. It’s essential to consider the type of ink used; water-based and solvent inks have specific requirements regarding film and fabric compatibility. Using the right materials from the outset saves time, prevents blurring or fading, and results in professionally printed t-shirts that look as good as they feel.

Step-by-Step Guide: From Image Preparation to Final Product

Step-by-Step Guide: From Image Preparation to Final Product

1. Image Selection and Preparation: Begin by choosing a high-resolution image, graphic, or design that you wish to print on the t-shirt. Ensure it’s optimized for DTF (Direct-to-Film) printing, meaning it has the correct dimensions, color profile, and file format (typically PNG or JPEG). Adjusting the image for optimal contrast and clarity is crucial to ensure a crisp final product. Crop, resize, and enhance the design using graphic design software as needed.

2. Film Preparation: Next, prepare the transfer film by selecting the appropriate material for your t-shirt type. Different films are designed for cotton, polyest, or mixed fabrics. Cut the film to match the design dimensions, ensuring precise alignment during printing. Ensure the film is clean and free of any debris before loading it into your DTF printer.

3. Printing Process: Load the prepared image onto your DTF printer. Calibrate the colors and ensure the print settings are optimized for the type of ink and film you’re using. Start the printing process, allowing the ink to precisely transfer from the image to the film. This step demands precision; misalignments can lead to imperfections in the final design.

4. Application: Once printing is complete, carefully remove the transfer film from the printer. Apply heat (using a heat press or iron) to activate the ink and firmly adhere it to the t-shirt. Ensure even pressure across the entire design area for a smooth, professional finish. Remove any excess film or debris from the shirt’s surface.

5. Curing: Allow the printed design on the t-shirt to cool down before handling it. Proper curing ensures that the ink sets correctly, preventing smudging or fading. Follow manufacturer guidelines for optimal cure times and temperatures for best results.

6. Quality Check: Inspect your final product under good lighting to ensure the colors are vibrant and the design is crisp and free of any printing errors or misalignments.

Creative Possibilities: Designing Stunning Visuals for Your Tees

Direct-to-film (DTF) printing opens up a world of creative possibilities for designing stunning visuals on t-shirts. With this innovative technique, artists and designers can seamlessly integrate high-quality images, intricate patterns, and vibrant colors directly onto the fabric, creating unique and eye-catching garments. DTF Printing allows for a level of customization that traditional printing methods struggle to match, empowering creators to bring their most bold and imaginative concepts to life.

From artistic illustrations to photographic masterpieces, the versatility of DTF Printing knows no bounds. It enables the reproduction of detailed designs with remarkable clarity and precision, making it an ideal choice for everything from fashion-forward streetwear to expressive personal statements. Whether you’re a seasoned graphic designer or a hobbyist looking to elevate your tee collection, embracing direct-to-film transfers can transform your t-shirts into wearable pieces of art that stand out from the crowd.

Best Practices and Troubleshooting Tips for Optimal DTF Results

When working with direct-to-film (DTF) transfers for decorating t-shirts, adhering to best practices ensures optimal results. First, choose high-quality DTF films designed specifically for textile printing. These films offer superior color vibrancy and longevity on various fabric types. Ensure your design is prepared correctly; use vector graphics or high-resolution raster images to avoid pixelation or distortion when transferred. Precise cutting is key; carefully trim the excess film around the design to prevent ink bleeding or smudging during the printing process.

Troubleshooting tips can help overcome common DTF challenges. If your print quality is poor, double-check your printer settings and ensure they match the DTF film’s specifications. Adjusting resolution, color profiles, and print mode might significantly improve outcomes. Regularly cleaning your print head and using suitable ink types also prevent clogging and ensure consistent, vibrant prints. Lastly, allow sufficient drying time for the ink to set properly; this prevents smudging or rubbing off during handling or washing.