Direct-to-Film (DTF) printing is an innovative game-changer in print production, offering a modern alternative to traditional screen printing methods. It enables digital imaging directly onto diverse materials like fabric, paper, and plastics, delivering superior quality prints with vibrant colors and sharp details. DTF stands out for its versatility, cost-effectiveness, and rapid turnaround times, making it an attractive option across various industries, particularly in custom apparel, promotional merchandise, signage, and car wraps. By eliminating the need for individual screen setup, DTF significantly shortens production times and reduces costs, positioning it as a competitive choice over traditional methods despite higher initial setup costs.

In the ever-evolving world of printing, Direct-to-Film (DTF) technology has emerged as a game-changer, challenging the traditional screen printing method. This article delves into the intricate details of both techniques, offering a comprehensive comparison. From understanding the unique benefits of DTF prints to analyzing their quality and exploring diverse applications, we uncover why this modern approach is revolutionizing the industry. By evaluating cost-effectiveness and production efficiency, businesses can make informed decisions, embracing the future of printing with DTF.

- Understanding Direct-to-Film (DTF) Prints: An Overview

- Traditional Screen Printing: The Conventional Method

- Production Process Comparison: DTF vs. Screen Printing

- Quality and Detail Analysis: Which Offers Better Results?

- Applications and Use Cases: Where DTF Outshines Traditional Printers

- Cost and Efficiency Evaluation: Making the Business Case for DTF

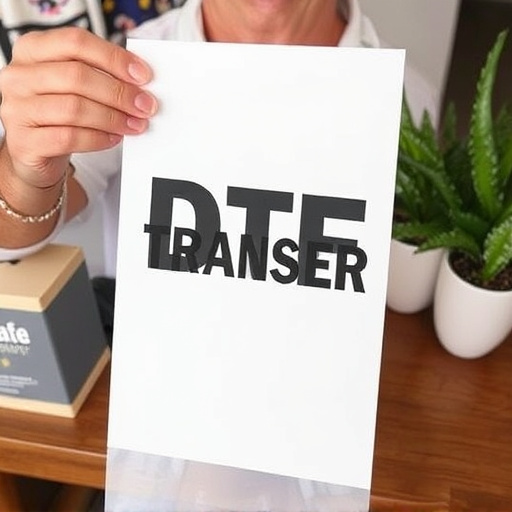

Understanding Direct-to-Film (DTF) Prints: An Overview

Direct-to-Film (DTF) printing is a cutting-edge method that has revolutionized the way we produce prints, especially in comparison to traditional screen printing. This modern technique allows for digital imaging directly onto various materials, including fabric, paper, and plastics. DTF Prints offer several advantages over conventional methods. With DTF, there’s no need for physical screens, which makes the process faster and more efficient. It enables high-quality, detailed prints with vibrant colors and sharp images, making it an attractive option for many industries.

The beauty of DTF lies in its versatility. It can handle complex designs and fine line details seamlessly, ensuring accuracy and precision. This method is particularly useful for short-run productions or creating unique, personalized items, as it offers a cost-effective solution without compromising on quality. Additionally, DTF Prints provide faster turnaround times, making them ideal for businesses and individuals seeking swift production and delivery.

Traditional Screen Printing: The Conventional Method

Traditional screen printing, often referred to as the conventional method, involves creating a stencil on a fine mesh or screen. This process begins with setting up a screen by stretching a thin, flexible material (like silk or synthetic fabrics) over a frame. The design is then transferred onto the screen using emulsion, which hardens when exposed to light. After the emulsion hardens, the areas that correspond to the design’s white spaces are coated with ink, while the open areas (the design itself) allow ink to pass through. This creates a stencil that acts as a template for printing. The process is then repeated on different screens for each color in the design, ensuring precise and vibrant DTF prints.

This traditional method offers excellent control over detail and line work but can be time-consuming and labor-intensive, especially for complex designs or limited runs. It’s a preferred choice for high-quality art and promotional items where precision and durability are paramount.

Production Process Comparison: DTF vs. Screen Printing

Direct-to-film (DTF) printing and traditional screen printing are two distinct methods with unique production processes. In screen printing, a physical screen or mesh is used to apply ink onto the substrate. This involves several steps: setting up the screen with the design, preparing the ink by mixing it with solvent or emulsion, and then pressing ink through the open areas of the screen onto the material below. The process allows for intricate detail but can be time-consuming and requires specialized equipment and skill.

In contrast, DTF printing offers a more straightforward approach. It utilizes modern technology to print directly onto various materials using inkjet printers. Designs are sent from a computer to the printer, which then precisely deposits ink onto the substrate without the need for screens. This method is significantly faster, making it ideal for quick production runs and diverse applications. DTF prints also boast vibrant colors and can produce high-resolution images, appealing to a wide range of industries.

Quality and Detail Analysis: Which Offers Better Results?

When comparing direct-to-film (DTF) prints to traditional screen printing, one of the key factors to consider is print quality and detail. DTF technology has made significant strides in recent years, offering a level of precision and sharpness that was previously unattainable in other methods. This modern approach allows for intricate designs with fine lines and subtle details to be reproduced accurately on a variety of surfaces.

On the other hand, traditional screen printing, while still widely used and beloved by many, may not match the level of detail that DTF prints can achieve. The nature of the process involves creating a stencil on a screen, which can sometimes result in slightly blurred or less precise edges, especially with complex artwork. However, traditional screen printing remains a powerful tool for creating bold, solid colors and large-scale graphics, where clarity and detail are not as critical as overall impact.

Applications and Use Cases: Where DTF Outshines Traditional Printers

Direct-to-film (DTF) prints have emerged as a game-changer in various industries, offering unique advantages over traditional screen printing methods. One of the standout applications of DTF technology is in custom apparel and promotional merchandise. With DTF, businesses can effortlessly create personalized designs on a wide range of fabrics, from t-shirts to hoodies, allowing for an extensive spectrum of use cases. This method enables rapid production, making it ideal for meeting the demands of fast-paced trends and events, such as creating limited-edition clothing lines or promotional items for marketing campaigns.

Additionally, DTF prints excel in fields requiring high-quality, detailed imagery, like signage and advertising. The capability to print directly onto various materials, including plastics, metals, and even acrylics, opens up a world of possibilities for creative designers and marketers. From eye-catching trade show displays to intricate window graphics, DTF offers vibrant colors, sharp details, and a level of versatility that traditional screen printing struggles to match. This technology is also favored in industries like automotive, where custom car wraps and detailed accessories are in high demand.

Cost and Efficiency Evaluation: Making the Business Case for DTF

Direct-to-film (DTF) printing offers a compelling alternative to traditional screen printing, particularly for businesses looking to streamline their production processes and reduce costs. One of the primary advantages lies in its efficiency—DTF eliminates the need for setting up individual screens for each design, which is both time-consuming and labor-intensive in conventional screen printing. This simplification results in faster turnaround times, allowing businesses to respond swiftly to market demands and customer needs.

Moreover, DTF prints prove more cost-effective on a per-print basis, especially for smaller orders or complex designs with intricate details. While initial setup costs for DTF equipment may be higher than traditional screen printing presses, the long-term savings become evident in lower material and labor expenses per print. This makes DTF an attractive option for businesses aiming to maximize profitability while maintaining high-quality output, ensuring a competitive edge in today’s market.