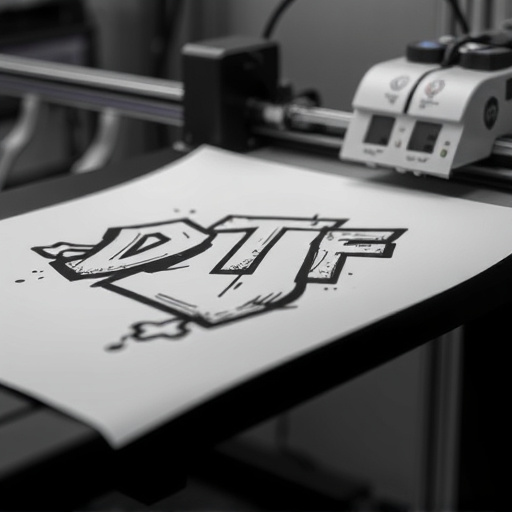

Direct-to-Film (DTF) transfers revolutionize printing with unparalleled speed and durability, eliminating traditional steps for vibrant, precise prints in 24 hours. This method, suitable for art to signage, caters to time-sensitive projects like last-minute events and emergency repairs. Skilled technicians ensure high quality despite tight turnarounds through optimized workflows and advanced equipment. DTF's future promises richer colors, faster speeds, and broader applications thanks to innovations in ink and printing technology, plus automation and AI integration.

In today’s fast-paced media landscape, the demand for direct-to-film (DTF) transfers has surged, especially with the rise of independent filmmakers and content creators. The ability to swiftly produce high-quality DTF prints within 24 hours can significantly impact production timelines and budgets. This article explores the accelerated production of DTF transfers, delving into techniques, quality assurance, business benefits, and future trends, empowering professionals to harness the power of this innovative technology for seamless content delivery.

- Understanding Direct-to-Film (DTF) Transfers: A Brief Overview

- The Demand for Rapid DTF Production: Why 24 Hours Matter

- Unlocking the Process: Techniques for Expedited DTF Printing

- Ensuring Quality: Maintaining Precision in Quick Turnaround

- Benefits of 24-Hour DTF Transfer Services for Businesses

- Future Prospects: Trends and Innovations in DTF Technology

Understanding Direct-to-Film (DTF) Transfers: A Brief Overview

Direct-to-Film (DTF) Transfers are a cutting-edge method revolutionizing the printing industry, especially for creating high-quality, durable prints. This process eliminates the need for traditional intermediate steps, such as printing onto film or paper, and instead allows for the direct transfer of digital data to a photosensitive material. DTF Printing offers unparalleled speed and efficiency, enabling the production of direct-to-film transfers within just 24 hours.

The technology behind DTF involves specialized inks and materials that react to light, creating precise and vibrant prints. When a digital image is sent to the printer, it exposes specific areas of the film or plate, hardening the ink in those locations while leaving other areas unexposed. This allows for intricate details and accurate color reproduction, making DTF ideal for various applications, from fine art printing to commercial signage.

The Demand for Rapid DTF Production: Why 24 Hours Matter

In today’s fast-paced media landscape, there is an increasing demand for quick turnaround times when it comes to film and photography. The expedited production of direct-to-film (DTF) transfers within 24 hours has become a game-changer for many industries. This rapid process caters to the need for immediate access to high-quality prints, ensuring that clients receive their DTF prints swiftly, without compromising on resolution or colour accuracy.

The ability to produce DTF transfers in just 24 hours is particularly valuable for emergency situations, last-minute events, and time-sensitive projects. Whether it’s a film festival requiring promotional materials, a photographer needing to print memories from a recent trip, or a small business wanting to quickly adapt their marketing materials, the speed of DTF printing offers immense flexibility. This efficiency not only saves time but also reduces costs, making it an attractive option for both professionals and enthusiasts alike.

Unlocking the Process: Techniques for Expedited DTF Printing

The process of creating direct-to-film (DTF) transfers isn’t just about speed; it’s a delicate dance between technology and art. Unlocking the potential for 24-hour turnaround times involves a combination of sophisticated techniques. Key among these is the utilization of advanced printing technologies that can lay down ink with precision, ensuring sharp details and vibrant colors in each DTF print.

Specialized materials play a crucial role too. From high-quality films to inks designed for optimal adhesion and durability, every component contributes to the final product’s quality. Additionally, streamlined workflows and automated systems help streamline the process, minimizing human error and maximizing efficiency. This blend of technological sophistication and meticulous material selection allows for the rapid production of DTF transfers without sacrificing quality or reliability.

Ensuring Quality: Maintaining Precision in Quick Turnaround

In the race to deliver content swiftly, maintaining quality becomes an art. When it comes to direct-to-film (DTF) transfers, achieving precision in a 24-hour turnaround is no easy feat. Skilled technicians must meticulously calibrate each step of the process to ensure the final DTF print lives up to its name—a perfect replica of the original material. From color accuracy to resolution, every detail matters, especially with time constraints.

The secret lies in streamlined workflows and state-of-the-art equipment. By employing efficient methods and high-performance printers, professionals can capture intricate details while meeting the tight deadline. Regular quality checks and a deep understanding of DTF printing techniques enable them to make on-the-fly adjustments, ensuring the output remains exceptional despite the rapid production pace.

Benefits of 24-Hour DTF Transfer Services for Businesses

The expedited production of direct-to-film (DTF) transfers within 24 hours offers significant advantages for businesses in various industries. One of the key benefits is the ability to streamline their content creation and distribution processes, ensuring that high-quality prints are available on demand. This efficiency is particularly valuable for time-sensitive projects, such as short-run promotions, event materials, or emergency repairs, where quick turnaround times are essential.

Additionally, 24-hour DTF transfer services provide cost-effectiveness by minimizing storage and inventory management overheads. Businesses no longer need to maintain large stock levels of pre-printed materials, reducing the risk of obsolete inventory and associated waste. Instead, they can rely on on-demand printing, producing only what is needed, when it’s needed, thereby optimizing resource utilization and maximizing return on investment.

Future Prospects: Trends and Innovations in DTF Technology

The future of direct-to-film (DTF) technology looks promising, with continuous innovations pushing the boundaries of what’s possible in such short production times. As demand for on-demand printing and rapid turnaround continues to grow, DTF transfers are expected to become even more prevalent across various industries. Emerging trends include advancements in ink formulations, enabling richer colors and enhanced durability for DTF prints. Printing technologies themselves are evolving, with newer, more efficient machines capable of producing high-quality DTF transfers at unprecedented speeds.

Additionally, the integration of automation and AI promises to streamline the entire process, from design input to final print output. This not only accelerates production times but also ensures consistency in quality. With these innovations, DTF technology is poised to offer even more versatility, making it suitable for a broader range of applications, from promotional merchandise to custom art pieces. The ability to create high-quality, unique items within 24 hours opens up exciting possibilities for businesses and individuals alike.