Direct-to-film (DTF) transfers are cutting-edge printing technology that directly projects high-quality images onto various surfaces. With diverse size options like A3, A4, and A5, DTF offers precise color matching, sharp details, and vibrant outcomes for signage, packaging, clothing, art, and more. The future of DTF looks promising with advancements expected in resolution and material integration, revolutionizing industries and creative possibilities.

Direct-to-film (DTF) transfers have revolutionized printing, offering precise and high-quality applications across various industries. This article delves into the intricacies of categorizing DTF transfers based on dimensional measurements, exploring how size impacts print quality and use cases. From vibrant, bustling displays to intricate details in art and design, understanding these dimensions is crucial for maximizing DTF printing potential. We’ll cover everything from the fundamentals to future trends, providing insights for both professionals and enthusiasts alike.

- Understanding Direct-to-Film (DTF) Transfers: A Basic Overview

- Categorizing DTF Transfers by Dimensional Measurements

- The Impact of Size on Print Quality and Applications

- Popular DTF Transfer Sizes and Their Use Cases

- Factors Influencing the Choice of Dimensional Measurements

- Future Trends in DTF Printing: Dimensional Innovations

Understanding Direct-to-Film (DTF) Transfers: A Basic Overview

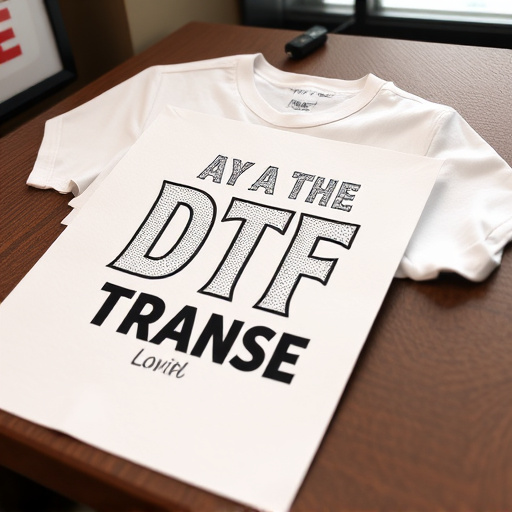

Direct-to-film (DTF) transfers are a cutting-edge printing technology that allows for high-quality reproduction of images and graphics directly onto various surfaces, including film and other media. This innovative process bypasses traditional intermediate steps, such as printing to paper, offering several advantages. DTF Printing enables precise color matching, sharp details, and vibrant outcomes, making it popular among artists, designers, and businesses seeking exceptional visual representations.

The DTF Transfer method involves using specialized equipment to project the desired image onto the target surface, typically a film or polymer sheet. This direct approach ensures that every pixel is accurately transferred, resulting in precise and detailed prints. Whether for signage, packaging, or special effects, DTF Transfers produce durable, long-lasting images, making them suitable for both indoor and outdoor applications. This technology’s versatility and ability to create indelible prints have revolutionized various industries, offering a game-changing solution for those seeking high-impact visual communications.

Categorizing DTF Transfers by Dimensional Measurements

Direct-to-film (DTF) transfers have revolutionized the way we create and reproduce visual content, especially in the context of printing. These transfers are categorized by their dimensional measurements, which play a crucial role in determining the final print quality and application. The process involves transferring ink directly onto a film surface, enabling precise reproduction of designs on various substrates.

DTF Printing offers a wide range of options based on dimensions, ensuring optimal results for different projects. Measurements such as width, length, and thickness are considered to classify these transfers. For instance, DTF prints can be categorized into standard sizes like A4 or larger formats suitable for billboards. This classification aids in selecting the appropriate transfer for specific needs, whether it’s for clothing, signage, or even art installations, ensuring vibrant and detailed DTF prints every time.

The Impact of Size on Print Quality and Applications

The size of a direct-to-film (DTF) transfer plays a significant role in determining the overall print quality and suitable applications. Smaller DTF transfers often result in finer details and sharper images, making them ideal for intricate designs and high-resolution artwork. This precision allows for complex patterns, fine lines, and subtle gradients to be reproduced accurately, which is particularly important for photo prints, graphic novels, or artistic illustrations. However, reducing the size can also mean a more limited print area, suitable only for smaller formats like postcards, stickers, or compact posters.

Conversely, larger DTF transfers offer a broader canvas for printing, enabling full-bleed images without any visible borders. This makes them perfect for showcasing large-scale artwork, murals, or high-impact advertising displays. While sacrificing some detail, bigger DTF prints can handle bolder colors and coarser textures effectively. They are commonly used in commercial printing, window graphics, vehicle wraps, and outdoor signage where the focus is on impactful visuals rather than intricate details.

Popular DTF Transfer Sizes and Their Use Cases

Direct-to-film (DTF) transfers come in various sizes, each with its own set of use cases and advantages. The most popular dimensions include A3, A4, and A5, catering to different printing needs. A3 transfers are ideal for larger designs or high-resolution prints, such as billboards or large-scale wall art. They offer a vast area for intricate details and vibrant colors, making them a favorite among professional artists and graphic designers.

Smaller sizes like A4 and A5 are perfect for more detailed and precise work, including small-scale artwork, logos, and personalized items like business cards or custom stickers. DTF printing in these dimensions allows for meticulous craftsmanship and high-quality results, making it a go-to choice for crafters, small businesses, and individuals looking to create unique, tailored prints.

Factors Influencing the Choice of Dimensional Measurements

When considering the dimensional measurements for a direct-to-film (DTF) transfer or print, several factors come into play. The primary consideration revolves around the intended use and display of the final product. For instance, a DTF Transfer designed for window graphics or signage may require specific dimensions to accommodate the glass or surface it will be applied to. On the other hand, a print meant for a poster or banner would have different size requirements, focusing on impact and visibility at a distance.

Furthermore, the choice of measurements can also depend on the printing technology used in DTF Printing processes. Different technologies offer varying levels of precision and detail reproduction, influencing the optimal print size. For high-resolution prints, smaller dimensions may be preferred to capture intricate details without compromising visual clarity, while larger sizes are suitable for more generic or artistic DTF Prints that can afford to showcase broader design elements.

Future Trends in DTF Printing: Dimensional Innovations

As technology evolves, Direct-to-film (DTF) transfers are expected to see significant advancements in dimensional capabilities. Future innovations will likely involve higher resolution prints, enabling more intricate and detailed DTF designs. This shift towards enhanced dimensionality could revolutionize various industries, from fashion and textiles to signage and packaging. With the ability to produce three-dimensional or textured DTF prints, brands can create unique visual experiences, captivating consumers in new ways.

Researchers and manufacturers are exploring innovative printing techniques, such as multi-material printing and advanced ink formulations, to achieve these dimensional improvements. These developments promise to expand the creative possibilities for designers and artists, allowing them to bring their visions to life with enhanced depth and realism. Additionally, the integration of smart materials and interactive features into DTF transfers may open doors to dynamic and responsive prints, further elevating the overall customer experience.