Direct-to-Film (DTF) transfer and traditional screen printing are two distinct print methods. DTF uses digital technology to directly transfer images, offering faster production times, extreme design flexibility, high-quality outcomes, and cost-effectiveness with eco-friendly waste reduction. Traditional screen printing, though labor-intensive, provides durable, long-lasting prints with bold colors and large-scale graphics, catering to industries like apparel and signage. Choosing between them depends on budget and needs: DTF for swift turnaround times and traditional screen printing for consistent quality across larger runs or intricate designs.

In the realm of print technology, the direct-to-film (DTF) transfer method has emerged as a modern alternative to traditional screen printing. This article delves into the comparison between these two methods, examining key factors such as quality, precision, turnaround time, cost, and suitable applications. Understanding the nuances of DTF Transfer can help businesses make informed decisions, ensuring they optimize their printing processes for superior results and enhanced efficiency, whether relying on DTF Printing or traditional techniques.

- Understanding Direct-to-Film (DTF) Transfer: A Modern Approach

- Traditional Screen Printing: The Time-Tested Method

- DTF vs. Traditional Printing: Quality and Precision

- Turnaround Time and Efficiency: Who Comes Out On Top?

- Cost Analysis: Weighing the Financial Implications

- Applications and Popular Use Cases for Each Technique

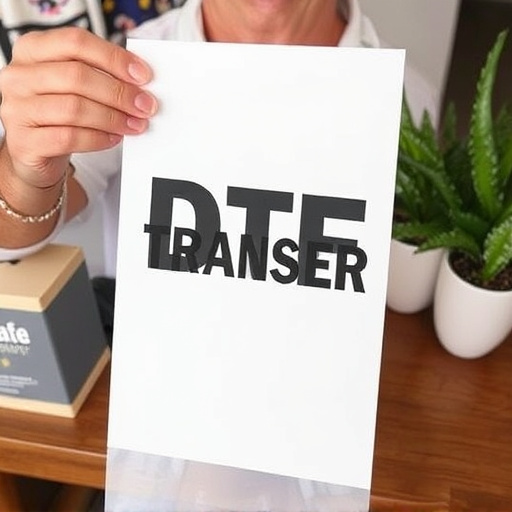

Understanding Direct-to-Film (DTF) Transfer: A Modern Approach

Direct-to-Film (DTF) transfer is a modern printing approach that has revolutionized the way we create custom prints and designs. Unlike traditional screen printing methods, DTF utilizes a digital process where images are transferred directly onto various materials, such as textiles or paper, using specialized inkjet printers. This innovative technique offers several advantages, including faster production times and unparalleled design flexibility. With DTF Printing, complex artwork with fine details and vibrant colors can be achieved without the need for intricate screen setup.

DTF prints have gained popularity due to their high-quality outcomes and cost-effectiveness. The process involves printing directly onto the target surface, eliminating the requirement for screens or plates, which reduces waste and makes it an eco-friendly option. This modern approach allows for on-demand printing, enabling businesses and artists to create personalized products quickly and efficiently. Whether for fashion, marketing materials, or artistic expressions, DTF Transfer has become a go-to method for achieving professional and visually appealing results.

Traditional Screen Printing: The Time-Tested Method

Traditional screen printing has been a tried and tested method for decades, offering precise and vibrant prints on a variety of materials. This time-honored technique involves creating a stencil on a fine mesh or screen, which is then coated with ink. As the ink is pushed through the open areas of the screen, it transfers the design onto the substrate below, resulting in high-quality DTF (Direct-To-Film) prints. This process allows for intricate details and rich colors, making it popular among artists and designers.

In contrast to modern DTF transfer methods, traditional screen printing offers a hands-on experience, requiring skill and precision. Each print is created individually, ensuring uniqueness and personal touch. While it might be more labor-intensive, this method has proven its worth in producing durable and long-lasting DTF prints, catering to various industries from apparel to signage.

DTF vs. Traditional Printing: Quality and Precision

Direct-to-film (DTF) printing and traditional screen printing are two distinct methods with unique advantages and considerations when it comes to quality and precision. DTF involves transferring ink directly onto a substrate from a film, offering several benefits in terms of detail and accuracy. This method allows for intricate designs with fine lines and subtle gradients, making it ideal for high-resolution prints. The precision of DTF ensures that every element of the design is reproduced exactly as intended, resulting in exceptional quality, especially for complex artwork.

In contrast, traditional screen printing relies on a physical stencil to transfer ink onto the material. While this method has long been trusted for its durability and versatility, it may not achieve the same level of detail as DTF. Screen printing is more suitable for bold, solid colors and large-scale graphics, where precision is less critical. However, for intricate patterns and fine details, DTF transfers excel, providing a superior finish for DTF prints.

Turnaround Time and Efficiency: Who Comes Out On Top?

Direct-to-film (DTF) transfer and traditional screen printing both have their strengths when it comes to turnaround time and efficiency, but they cater to different needs. DTF printing offers a significant advantage in speed—it can produce high-quality prints on various materials in a fraction of the time compared to screen printing. This method is ideal for orders with tight deadlines, such as those from small businesses or event organizers who require quick turnaround times without compromising quality.

In contrast, traditional screen printing while more labor-intensive, allows for greater control and customization. It’s suited for larger runs where speed isn’t the primary concern. The setup time for screen printing might be longer, but it ensures consistent quality across multiple prints, making it a preferred method for large-scale production or when creating unique, intricate designs.

Cost Analysis: Weighing the Financial Implications

Direct-to-film (DTF) transfer and traditional screen printing methods have distinct financial implications that should be carefully considered when choosing a print approach. DTF printing involves using heat presses to apply designs directly onto various materials, eliminating the need for separate screens. This simplicity results in potentially lower upfront costs compared to setting up a traditional screen printing system. However, DTF transfers may require more frequent replacement due to their single-use nature, which can increase long-term expenses.

In contrast, traditional screen printing offers higher initial investment costs because it necessitates the creation of individual screens for each design. Yet, these screens are reusable, making subsequent prints more cost-effective. Moreover, screen printing allows for a broader range of ink and material options, enabling specialists to achieve unique effects and cater to diverse client demands. This versatility can be particularly beneficial for businesses targeting niche markets or creating custom, one-off DTF prints.

Applications and Popular Use Cases for Each Technique

Applications and Popular Use Cases for Each Technique

Direct-to-film (DTF) transfer has gained significant traction in recent years, primarily due to its versatility and efficiency. This modern method is ideal for creating custom prints on a wide range of materials, including t-shirts, hoodies, mugs, and even fabric banners. DTF printing offers a seamless, high-quality solution for both small-scale and bulk production runs, making it popular among small businesses, startups, and event organizers looking to create unique, personalized products quickly.

In contrast, traditional screen printing remains a go-to method in industries where durability and vibrant colors are paramount, such as promotional merchandise, signage, and even some garment manufacturing. Its ability to handle intricate designs and multiple color layers makes it suitable for creating detailed artwork and complex logos. While traditionally slower and more labor-intensive than DTF, screen printing continues to be a reliable choice for high-volume production runs where cost-effectiveness and long-lasting prints are essential.