In extreme conditions, high-performance vehicles require robust performance exhaust systems to manage intense engine heat. These systems use advanced materials and insulation, smart heat flow design, and integrated components like stainless steel pipes and optimized headers for longevity. Rigorous testing, optimization with simulation tools, material science advancements, and regular weld quality checks ensure system integrity under demanding circumstances.

In the realm of automotive engineering, high-performance exhaust systems face unique challenges. These systems must endure extreme temperatures generated by powerful engines, demanding enhanced durability and efficiency. This article delves into the critical aspects of designing and optimizing a performance exhaust system built to handle such harsh conditions. We explore key components, testing methodologies, and optimization strategies to ensure optimal performance and longevity in extreme environments.

- Understanding High-Temperature Challenges in Exhaust Systems

- Key Components for Effective High-Performance Exhaust Design

- Testing and Optimization Strategies for Extreme Conditions

Understanding High-Temperature Challenges in Exhaust Systems

In the realm of automotive performance, a well-engineered performance exhaust system is paramount, especially when tackling extreme temperatures. High-performance vehicles generate immense power, resulting in scorching heat within their exhaust systems. This presents several challenges for traditional components, which can succumb to warping, cracking, or even premature failure under prolonged exposure to such intense conditions. The constant flux of hot gases exerts significant pressure on the system, particularly at higher RPMs, making heat resistance and durability critical.

One of the primary considerations is managing the heat signature generated by the engine, especially around critical parts like exhaust mufflers and exhaust pipes. Overheated components can lead to reduced performance and even pose safety risks. Therefore, a robust performance exhaust system designed for high-temperature endurance must incorporate advanced materials and innovative engineering solutions. This may include reinforced metal alloys, specialized insulation, and smart design elements that direct heat flow efficiently, ensuring the longevity and reliability of the exhaust system while preserving optimal vehicle performance.

Key Components for Effective High-Performance Exhaust Design

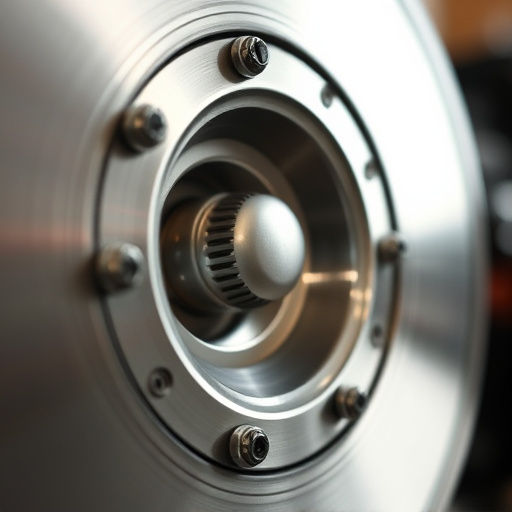

A performance exhaust system designed to handle high temperatures hinges on several key components working in harmony. First and foremost is the material used for the exhaust pipes; stainless steel is a popular choice due to its superior heat resistance and corrosion-free properties, ensuring longevity under extreme conditions. The exhaust headers play a crucial role in optimizing gas flow, and their design should facilitate efficient combustion gases expulsion.

Additionally, high-performance brakes, featuring robust brake pads, contribute to overall system effectiveness by enabling precise control during demanding driving conditions. Complementing this is the integration of cold air intakes which, by drawing in cool air, can enhance engine performance and reduce stress on the exhaust system, further extending its lifespan.

Testing and Optimization Strategies for Extreme Conditions

When developing a performance exhaust system designed to handle high temperatures, thorough testing and optimization are paramount. Extreme conditions simulate real-world scenarios, ensuring the system’s integrity and reliability under demanding circumstances. Engineers employ advanced simulation tools to predict performance before physical testing. This process involves subjecting components to intense heat, pressure, and corrosion resistance tests, mimicking the harsh environments of racing tracks or off-road trails.

Optimization strategies focus on material science and design refinement. High-performance exhaust systems often utilize advanced alloys that can withstand extreme temperatures without compromising strength or durability. Additionally, integrating innovative cooling mechanisms, such as liquid cooling components or strategic ventilation, helps manage heat buildup. Regular adjustments to the system’s design, including improvements in weld quality and joint integrity, contribute to overall performance and longevity, ensuring the exhaust system remains efficient even under intense conditions.

A well-designed performance exhaust system tailored for high-temperature applications is a game-changer for automotive enthusiasts. By understanding the unique challenges posed by extreme heat, incorporating vital components like advanced materials and efficient cooling mechanisms, and employing rigorous testing and optimization techniques, engineers can create exhaust systems that deliver both superior performance and longevity. This ensures an enhanced driving experience while tackling the demanding conditions of high-performance vehicles.