DTF Apparel Printing revolutionizes garment creation with direct fiber ink application, offering vibrant colors and intricate details on diverse fabrics, including dark ones. Ideal for limited-run productions, this technology provides designers flexibility, control, and eco-friendliness, minimizing storage costs and waste. The streamlined production process using DTF heat transfer paper and heat press ensures swift adaptation to fashion trends, making it a cost-effective solution for small-batch manufacturers catering to demanding consumers.

“Unleash your creativity with Direct to Fiber (DTF) printing, a game-changing technology for limited-run apparel production. This innovative process allows designers to easily bring unique, small-batch clothing ideas to life. From design to garment, DTF apparel printing offers precision, speed, and cost-effectiveness.

Explore the benefits, understand the process, and discover how this method democratizes fashion, empowering creators to print on demand without complex machinery or large investments.”

- Understanding Direct to Fiber (DTF) Printing Technology

- Benefits of Limited-Run Apparel Production for Designers

- DTF Printing Process: From Design to Garment

Understanding Direct to Fiber (DTF) Printing Technology

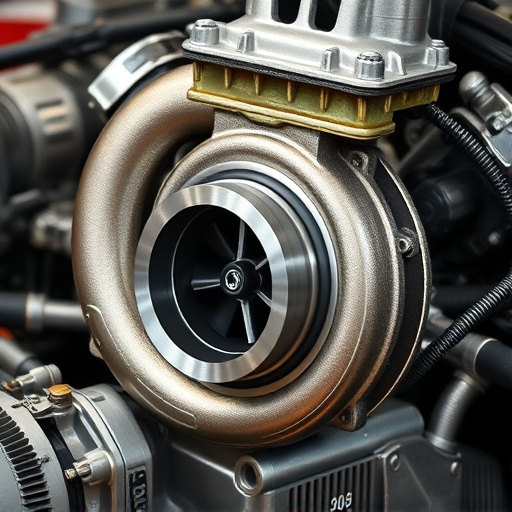

Direct to Fiber (DTF) Printing is a cutting-edge technology revolutionizing the apparel industry, especially for limited-run and custom designs. This innovative process eliminates the need for traditional printing methods, allowing designers and manufacturers to produce unique, personalized garments with precision and speed. DTF Apparel Printing directly applies ink onto textile fibers using specialized equipment, ensuring vibrant colors and intricate details on a variety of fabrics.

One key advantage lies in its versatility; it excels when applied to dark fabrics, offering rich, long-lasting colors that traditional methods might struggle with. Whether creating direct to film personalized hoodies or intricate dtf transfers, the technology enables the production of high-quality, customized apparel at scale. This makes DTF Printing an attractive option for those seeking a cost-effective and efficient way to bring their fabric designs to life, especially in today’s fast-paced fashion market.

Benefits of Limited-Run Apparel Production for Designers

Designers can greatly benefit from limited-run apparel production using DTF (Direct to Fiber) printing technology. This approach allows for smaller batch sizes, enabling creators to bring unique, niche designs to market without the usual high minimum order quantities. By producing just what’s needed, designers can minimize storage costs and reduce waste, making it an eco-friendly choice.

DTF Apparel Printing offers designers flexibility and control over their creations. They can experiment with various fabrics, colors, and styles, quickly adapting to changing trends and consumer demands. The use of dtf heat transfer paper and dtf transfer sheets streamlines the production process, allowing for efficient printing on a variety of garments. Additionally, a heat press further enhances speed and precision, ensuring high-quality results every time.

DTF Printing Process: From Design to Garment

The DTF (Direct to Fabric) printing process revolutionizes apparel production by enabling small-batch clothing manufacturers to create limited-run garments with ease and precision. It starts with a designer conceptualizing a unique print, which is then digitally transferred onto a special printing plate within a DTF printer. This plate is gently pressed against the fabric, depositing ink directly onto the garment’s surface. The result is a vibrant, detailed design that truly brings the original artwork to life.

Unlike traditional printing methods, DTF Apparel Printing allows for swift turnaround times and minimal waste, making it an eco-friendly option for small-scale producers. Once printed, the garments can be cured using heat or UV light, ensuring the ink sets permanently onto the fabric. This efficient workflow lets manufacturers swiftly move from design to garment, easily accommodating the demand for limited-edition pieces that resonate with trendy consumers in today’s fast-paced fashion landscape.

Direct to fiber (DTF) printing technology revolutionizes limited-run apparel production, offering designers an efficient and versatile option. By eliminating the need for costly set-ups and allowing for intricate designs, DTF apparel printing ensures that small batch productions can still boast high-quality results. This cutting-edge method opens doors for creative expression, enabling fashion enthusiasts to bring unique garments to life with ease.