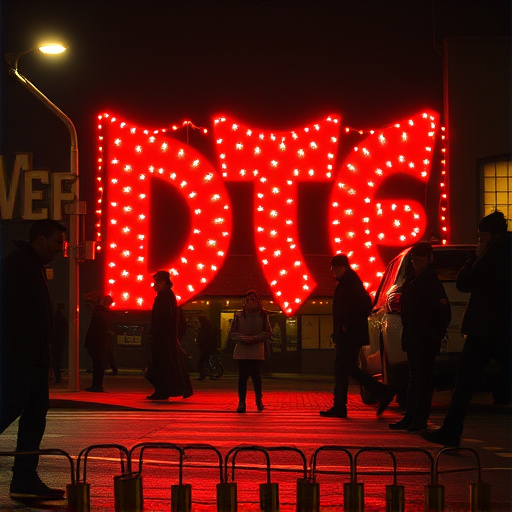

Prepare workspace with good ventilation, tools like mask, spatulas, heat press, and store DTF Powder in accessible container. Measure and evenly distribute DTF Adhesive Powder using fine-tipped brush for precise control, minimizing waste, enhancing adhesion on dark fabrics for DTF printing. Uniform distribution maximizes efficiency and ensures quality design transfer during heat pressing.

Looking to master the art of applying DTF Adhesive Powder without waste? This guide is your compass. We’ll walk you through preparing your workspace and tools, accurately measuring and applying the powder, and most importantly, spreading it uniformly to avoid excess. Master these steps, and you’ll achieve precise, efficient results every time, ensuring your DTF adhesive powder works as hard as you do.

- Prepare Your Workspace and Tools

- Measure and Apply Adhesive Powder Correctly

- Spread Powder Uniformly: Avoid Excess Waste

Prepare Your Workspace and Tools

Before you begin applying DTF Adhesive Powder, setting up your workspace and gathering the right tools is essential. Start by clearing a clean, well-lit area where you can work comfortably. Ensure proper ventilation to prevent inhaling any dust or fumes. Gather all necessary equipment, including a mask for protection, precision spatulas or brushes designed for powder application, and a heat press machine. For optimal results with DTF prints on fabrics like clothing brands, having a steady hand and the right tools will ensure minimal waste and precise control during the application process.

Organize your workspace by keeping your DTF Adhesive Powder in an easily accessible container and placing your tools within reach. A clean, organized area allows for a more efficient workflow and reduces the risk of spills or mess. This setup is crucial when working with delicate materials and powders like DTF, especially if you’re creating intricate designs for logos on clothing.

Measure and Apply Adhesive Powder Correctly

Proper measurement and application are key when using DTF Adhesive Powder to avoid waste and ensure optimal results. Start by carefully measuring the required amount based on your project’s scale and complexity. A precise measure prevents overapplication, reducing unnecessary powder usage. Once measured, evenly distribute the adhesive across the desired surface using a fine-tipped brush or applicator tool. This controlled application ensures full coverage without excess, enabling better adhesion when transferring designs to materials like DTF printing for dark fabrics, t-shirts, or creating direct-to-film personalized hoodies.

Spread Powder Uniformly: Avoid Excess Waste

To ensure optimal use of DTF Adhesive Powder and minimize waste, spreading the powder uniformly is key. This even application allows for precise control over the amount needed for each project, eliminating excess material that can compromise your design’s quality. Start by sifting a measured amount into your work area to achieve a smooth, consistent layer. The uniform spread not only saves powder but also ensures your custom dtf transfers and heat transfer paper adhere perfectly to the garment, preserving the intricate details of your custom sheets for heat pressing designs onto garments.

By meticulously preparing your workspace, measuring adhesive powder precisely, and spreading it uniformly, you can significantly reduce waste when applying DTF Adhesive Powder. This not only saves costs but also ensures a cleaner, more efficient application process, leaving you with minimal excess residue.