Straight pipe exhaust systems are performance boosters for turbocharged engines, offering minimal restrictions for efficient gas flow, enhanced power output, and improved throttle response. Their direct design provides a powerful sound and better vehicle dynamics, appealing to enthusiasts seeking a tailored driving experience. Installation is relatively simple, with proper alignment and sealing crucial for optimal performance, and these systems require minimal maintenance.

“Unleash the full potential of your turbocharged engine with a straightforward pipe exhaust system. This article delves into the fundamentals of straight pipe exhaust design, highlighting its unique advantages for turbo engines. We explore how this setup enhances performance, improves sound, and simplifies maintenance compared to complex headers. Discover the benefits, installation tips, and key considerations for integrating a straight pipe exhaust, making your engine modification journey smoother and more efficient.”

- Understanding Straight Pipe Exhaust System Basics

- Advantages of Using Straight Pipes for Turbo Engines

- Installation, Maintenance, and Performance Considerations

Understanding Straight Pipe Exhaust System Basics

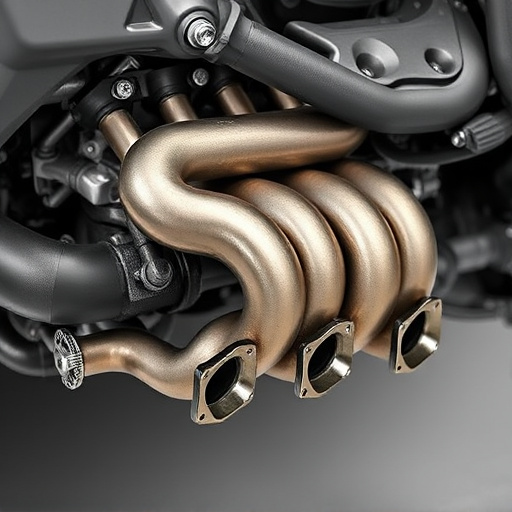

A straight pipe exhaust system is a fundamental component in enhancing the performance of turbocharged engines. Unlike curved or twisted exhaust systems, straight pipes are designed with a simple and direct flow, allowing gases to exit the engine efficiently. This configuration prioritizes minimal restrictions, which can significantly boost engine performance. By eliminating complex bends and reducers, straight pipes maintain the natural expansion of exhaust gases, resulting in increased power output and improved throttle response.

This type of exhaust system is often favored by enthusiasts and professionals alike due to its ability to provide a powerful sound and enhance overall vehicle dynamics. Unlike cat-back exhaust systems that include additional components for noise reduction, straight pipe exhausts offer a more open and direct path for gases, contributing to better performance brakes and improved engine management. Understanding these basics is crucial when customizing or upgrading turbocharged vehicles, ensuring both optimal performance and a tailored driving experience.

Advantages of Using Straight Pipes for Turbo Engines

Using straight pipe exhaust systems for turbocharged engines offers several advantages that enhance both performance and driving experience. Unlike twisted or bent headers, straight pipes provide a straightforward path for exhaust gases to flow, minimizing restrictions in the exhaust system. This direct routing allows for increased backpressure, which can boost engine power and torque output. By eliminating complex bends and chambers, straight pipes also simplify the installation process, making them a popular choice among enthusiasts looking to enhance their vehicles without extensive modifications.

Additionally, straight pipe exhaust systems contribute to better sound dynamics, producing a more aggressive and sporty exhaust note. This characteristic is often favored by those who enjoy the sensory experience of driving a high-performance vehicle. Moreover, these exhausts can integrate seamlessly with other performance upgrades, such as coilover kits and advanced air intake systems, to create a balanced and cohesive power delivery system, further enhancing the overall driving pleasure.

Installation, Maintenance, and Performance Considerations

The installation process for a straight pipe exhaust system is relatively straightforward, especially when compared to more complex forced induction setups. This simplicity makes it an attractive option for car enthusiasts looking to enhance their turbocharged engine’s performance. During installation, it’s crucial to ensure proper alignment and sealing of all components, particularly at the header flanges and exhaust outlets. Proper mounting ensures not only optimal performance but also prevents potential leaks that could lead to power loss.

Maintenance of a straight pipe exhaust system is largely dependent on the quality of materials used. High-performance stainless steel and aluminum alloys are common choices for their durability and resistance to corrosion, which are essential when dealing with high-temperature gases. Regular visual inspections should be conducted to check for any signs of damage or wear. Unlike complex air intake systems and intake components, straight pipe exhausts typically require minimal maintenance. However, keeping an eye on potential issues ensures the system’s longevity and maintains peak performance.

A straight pipe exhaust system offers a powerful performance upgrade for turbocharged engines, providing a direct path for gases to flow freely. By eliminating the complex curves and chambers found in traditional systems, these pipes enhance engine efficiency and reduce backpressure, resulting in improved horsepower and torque. While installation requires careful consideration, proper maintenance ensures longevity and optimal performance. Adopting a straight pipe exhaust system can be a game-changer for vehicle enthusiasts seeking to unleash the full potential of their turbocharged engines.