Oil fouling on automotive sensors causes inaccurate readings and potential failure, leading to safety concerns in modern vehicles with numerous critical sensors. A dry air filter prevents oil droplets and contaminants from entering the engine, ensuring clean air intake for optimal sensor precision. By filtering out moisture and particles, these filters enhance system reliability, reduce sensor degradation, extend brake component lifespan, improve vehicle safety, and increase overall efficiency, especially in high-performance exhaust systems.

Dry air filters play a crucial role in minimizing the risk of oil fouling on sensors, an issue that can cause significant sensor degradation and impact device performance. This article delves into the problem of oil fouling, exploring its causes and consequences in detail. We’ll uncover the surprising link between moisture and sensor degradation, and highlight how dry air filters act as a game-changer by providing a dry environment, thus preventing fouling and ensuring sensors operate at peak efficiency.

- Understanding Oil Fouling on Sensors

- The Role of Moisture in Sensor Degradation

- How Dry Air Filters Mitigate Risk

Understanding Oil Fouling on Sensors

Oil fouling on sensors is a common issue that can significantly impact various automotive systems. It occurs when oil from the engine, particularly when it becomes contaminated with dust, debris, or other particles, accumulates on sensitive sensor surfaces. This buildup can lead to inaccurate readings and, in some cases, complete sensor failure. In modern vehicles, where numerous sensors are used for optimal performance and safety, such fouling can cause significant problems.

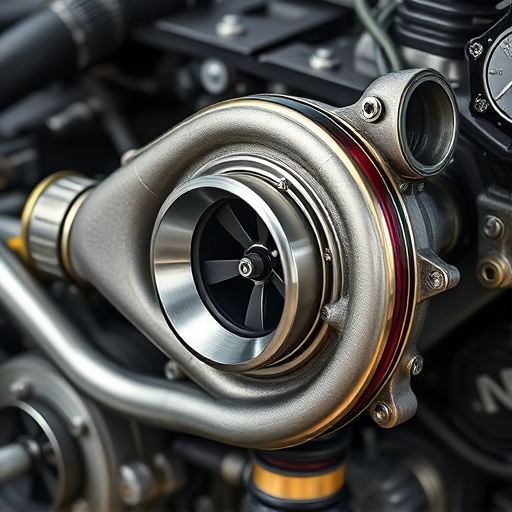

A dry air filter plays a crucial role in preventing this issue by ensuring that minimal oil droplets or contaminants enter the engine’s internal components, including sensors. Unlike traditional filters that rely on oil changes to maintain efficiency, a dry air filter continuously traps particles, keeping them from reaching critical systems like those responsible for monitoring engine performance, suspension components, and even brake rotors. By maintaining clean air intake, these sensors operate at peak precision, enhancing overall vehicle performance and safety.

The Role of Moisture in Sensor Degradation

Moisture plays a significant role in sensor degradation, which can lead to costly and inefficient equipment performance. Sensors, often exposed to various environmental conditions, are particularly vulnerable to moisture-related issues. When sensors come into contact with water vapour or liquid water, it can cause electrical interference and signal distortion. This interference disrupts the accuracy of readings and may result in false data, affecting critical decision-making processes.

In automotive applications, for instance, sensors are integral to engine management systems, ensuring optimal performance and fuel efficiency. A dry air filter is an effective solution to mitigate moisture ingress. By filtering out water vapour and contaminants from the incoming airflow, it creates a drier environment, reducing the risk of oil fouling on sensors. This is especially beneficial in vehicles with performance exhaust systems or cat back exhausts, where moisture accumulation can be more pronounced due to higher operating temperatures and engine bay environments. Air filter kits, designed for specific vehicle requirements, offer an easy retrofit solution to enhance sensor longevity and overall system reliability.

How Dry Air Filters Mitigate Risk

Dry air filters play a pivotal role in mitigating the risk of oil fouling on sensors within automotive systems. By ensuring a constant supply of clean, dry air, these filters prevent the accumulation of moisture and contaminants that can degrade sensor performance over time. Moisture, often carried by ambient air, can lead to the formation of condensate on sensitive components like brake rotors and sensors, causing them to malfunction or even fail prematurely.

Moreover, oil fouling occurs when engine oil, which is inherently oily and viscous, coats the surfaces of sensors, reducing their efficiency. Clean air filters trap microscopic particles of oil and other debris before they reach these crucial components, including brake pads and sensors integral to safe braking systems. By maintaining optimal operating conditions, dry air filters help extend the lifespan of brake components, thereby enhancing overall vehicle safety and performance.

Dry air filters play a crucial role in mitigating oil fouling on sensors, preventing degradation and ensuring optimal performance. By reducing moisture levels in the air, these filters create a drier environment, hindering the buildup of oil on sensor components. This simple yet effective solution is a game-changer for maintaining reliable sensor functionality, especially in industrial settings where dust and contaminants are prevalent. Adopting dry air filters can significantly extend sensor lifespan and minimize costly downtime caused by fouling.