Intercooler piping finishes impact both performance and aesthetics: polished for heat dissipation, coated for durability & corrosion resistance, wrinkle for superior airflow efficiency and rust resistance. Choice depends on prioritizing aesthetics (polished) or functionality (coated/wrinkle). Wrinkle finish excels in extreme conditions for high-performance vehicles.

Intercooler piping finishes—polished, coated, or wrinkle—offer diverse aesthetic and performance options for vehicle enthusiasts. Understanding these finishes is crucial when optimizing both looks and functionality of your intercooler system. This article delves into the nuances of each finish, highlighting how polished metal enhances visual appeal, while protective coatings safeguard against corrosion. We also explore the durability and performance benefits of wrinkle finish, a game-changer for rugged applications.

- Understanding Intercooler Piping Finishes

- Polished vs Coated: Aesthetic and Functionality

- Wrinkle Finish: Durability and Performance

Understanding Intercooler Piping Finishes

Intercooler piping finishes play a significant role in the performance and aesthetics of your vehicle’s cooling system. These finishes are designed to suit various needs, from enhancing heat dissipation to providing protection against corrosion. When discussing intercooler piping, three primary finish options stand out: polished, coated, and wrinkle (or textured).

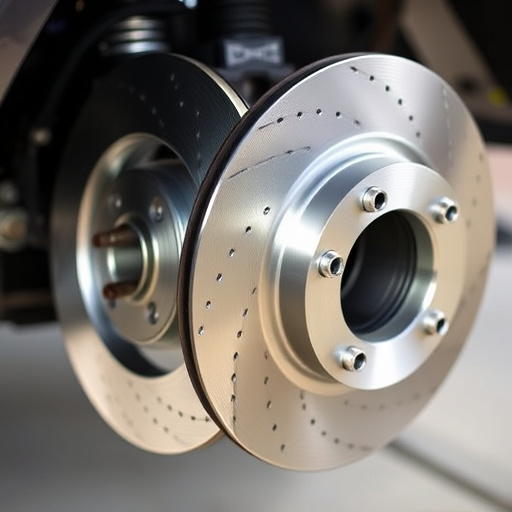

Polished intercooler piping is known for its sleek, mirror-like surface, reflecting light rather than absorbing it. This finish offers superior heat transfer capabilities, making it a favorite among those seeking optimal cooling performance. Coated piping, on the other hand, features an applied layer that can provide additional protection against rust and corrosion, ensuring longevity even in harsh driving conditions. Wrinkle finishes offer a more unique look, often chosen for their aesthetic appeal in high-performance vehicles, where style and functionality merge seamlessly with powerful engines and advanced components like custom air filter kits and high-performance brake rotors.

Polished vs Coated: Aesthetic and Functionality

When it comes to intercooler piping finishes, the choice between polished and coated offers a unique blend of aesthetics and functionality. Polished pipes exude a sleek, mirror-like finish that not only enhances the visual appeal of a vehicle’s underbelly but also facilitates better heat dissipation. This is particularly beneficial for high-performance vehicles where maintaining optimal engine temperatures is crucial for sustained vehicle performance. The reflective surface can help reflect heat away from the engine, reducing temperature spikes and ensuring consistent power output.

On the other hand, coated intercooler piping provides a more durable and protective layer over the metal. These coatings are designed to withstand extreme temperatures and resist corrosion, which is essential for maintaining the longevity of intercooler piping components. Additionally, certain coatings can contribute to noise reduction, especially in comparison to raw, polished metal. While it may not be as visually striking as a polished finish, the coated option offers a practical advantage, ensuring that your cat back exhaust and performance brakes remain reliable under intense conditions.

Wrinkle Finish: Durability and Performance

The Wrinkle Finish option for intercooler piping offers a unique advantage in terms of both durability and performance. This finish is designed to withstand extreme conditions, making it ideal for high-performance vehicles where reliability is paramount. The wrinkled surface acts as a barrier against corrosion and rust, which are common issues with metal components exposed to heat and moisture. Unlike polished or coated finishes that might be more susceptible to chipping or flaking under stress, the wrinkle finish provides a tough exterior that can take the brunt of driving conditions, from dusty trails to hot, crowded city streets.

Moreover, this finish enhances airflow efficiency within the intercooler system. The slight roughness of the wrinkled surface promotes better turbulence, ensuring optimal cooling performance even under heavy load. This is particularly beneficial for off-road enthusiasts and those who regularly push their vehicles to the limit, as it means consistent engine performance and reduced risk of overheating, a common issue with poorly cooled brake components and suspension kits.

When it comes to intercooler piping finishes, the choice between polished, coated, or wrinkle depends on your aesthetic preferences and performance needs. Polished piping offers a sleek, mirror-like finish for a refined look, while coated options provide added protection against corrosion. Wrinkle finish, on the other hand, excels in durability and performance, making it ideal for demanding environments. Ultimately, selecting the right intercooler piping finish allows you to balance visual appeal with optimal cooling efficiency.