Proper DTF Adhesive Powder application begins with clean, textured surfaces for enhanced adhesion. Evenly distribute measured powder using a smooth tool to ensure optimal print quality and strength for designs on fabric or wood, utilizing fine mesh sieves for intricate details.

“Achieving optimal results with DTF (Direct Thermal Transfer) adhesive powder requires a systematic approach. This article explores best practices for even application, ensuring superior adhesion and long-lasting durability. We’ll guide you through preparing surfaces, measuring and distributing the powder uniformly, and achieving comprehensive coverage. By following these steps, you can maximize the effectiveness of DTF adhesive powder, enhancing the overall quality of your projects.”

- Prepare Surface for Optimal Adhesion

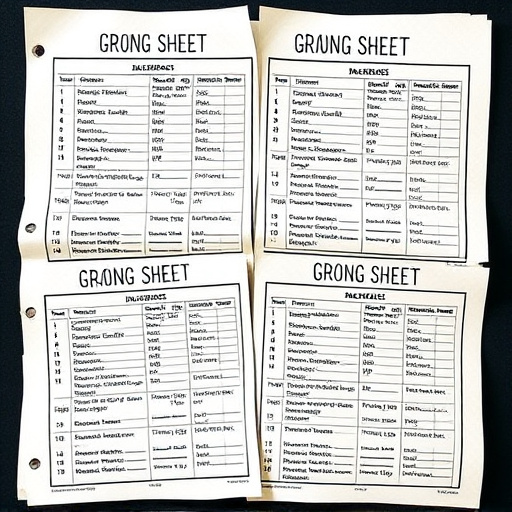

- Measure and Distribute Powder Uniformly

- Ensure Even Coverage for Strength and Durability

Prepare Surface for Optimal Adhesion

Before applying DTF Adhesive Powder, ensuring your surface is properly prepared is paramount for achieving even adhesion. Start by thoroughly cleaning and degreasing the area where you’ll be working to remove any contaminants or oils that could hinder the bonding process. This step is crucial, especially when preparing custom dtf transfers for apparel or applying DTF directly onto garments using heat pressing designs.

Next, consider the roughness or smoothness of the fabric or substrate. For optimal adhesion, a slightly textured surface can help create a mechanical bond with the DTF powder. Sanding or gently abrasing the area can increase friction and allow the adhesive to penetrate better. However, be cautious not to overdo it, as excessive roughening might damage the material’s texture or integrity.

Measure and Distribute Powder Uniformly

When applying DTF Adhesive Powder, uniform distribution is key to achieving optimal results. Start by accurately measuring the required amount of powder using a precise scale. This ensures that every application has the same consistency, critical for consistent print quality. Once measured, distribute the powder evenly across the surface using a smooth, flat tool. This could be a spatula or a special applicator designed for DTF Adhesive Powder, ensuring no clumps form and the layer is even.

For best results with a direct to film printer or heat press, consider the particle size of the powder. A uniform powder layer allows for even heat transfer during the pressing process, adhering the design perfectly to the substrate. This meticulous step is often overlooked but significantly impacts the final product’s quality, especially when using the best DTF printer available.

Ensure Even Coverage for Strength and Durability

Achieving even coverage with DTF Adhesive Powder is paramount for enhancing strength and durability in your projects. When applying the powder, aim for a consistent layer that coats the entire surface area intended for the design. This meticulous step ensures that the adhesive binds firmly to the substrate, whether it’s fabric, wood, or other materials commonly used in DTF printing, like hoodies. An even application prevents weak spots where adhesion might be lacking, leading to longer-lasting results.

For optimal results with your best DTF printer, consider adjusting the powder’s consistency and using a fine mesh sieve for accurate measurement. This approach is particularly beneficial when working with intricate designs or complex shapes. Remember that achieving the right coverage enhances not only the structural integrity but also the overall aesthetic appeal of cold peel DTF transfers, making them a popular choice in various creative applications.

Applying DTF adhesive powder evenly is crucial for achieving strong, durable bonds. By preparing the surface properly, measuring accurately, and ensuring even coverage, you can maximize the effectiveness of this versatile material. Remember that consistent application practices are key to achieving professional results with DTF Adhesive Powder in your projects.