Polyurethane bushings, crafted from durable synthetic polymers, excel in extreme conditions, offering wear resistance and consistent performance over time. Their strategic design balances flexibility for shock absorption with rigidity to withstand pressure, ensuring structural integrity in demanding automotive environments. Shape retention capabilities revolutionize various industries, enhancing durability, alignment precision, and vibration absorption, ultimately improving component and machinery longevity.

Polyurethane bushings have emerged as indispensable components in various industries, renowned for their versatility and exceptional load-bearing capabilities. This article delves into the world of these innovative materials, exploring their unique properties and how they maintain shape under heavy loads. We’ll discuss critical design considerations ensuring optimal performance, highlighting their diverse applications, and dissecting the benefits of shape retention in polyurethane components.

- Understanding Polyurethane Bushings: Materials and Properties

- Design Considerations for Load Resistance in Bushings

- Applications and Benefits of Shape Retention in Polyurethane Components

Understanding Polyurethane Bushings: Materials and Properties

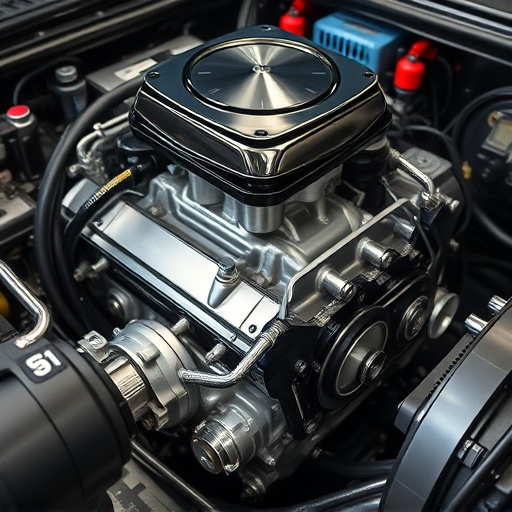

Polyurethane bushings are engineered components designed to withstand extreme conditions and maintain their shape under heavy loads. Crafted from a synthetic polymer, they offer a unique blend of properties that make them indispensable in various industries. The primary material, polyurethane, is renowned for its exceptional durability and resilience against wear and tear. This characteristic makes polyurethane bushings ideal for applications involving constant friction and impact, such as in automotive systems like performance air filters, exhaust mufflers, and brake components.

Their structural integrity ensures a consistent performance over time, even under demanding circumstances. Polyurethane’s flexibility allows these bushings to absorb shocks and vibrations, providing shock-absorbing capabilities that can prevent damage to interconnected parts. This property is particularly valuable in environments with high mechanical stress, ensuring the longevity of connected machinery and components, be it in heavy-duty vehicles or industrial equipment.

Design Considerations for Load Resistance in Bushings

When designing polyurethane bushings intended to withstand heavy loads, several factors come into play. The primary consideration is material selection, where high-quality polyurethanes with exceptional mechanical properties are chosen to ensure durability and resistance. These materials should offer a balance between flexibility for shock absorption and rigidity to maintain their shape under extreme pressure.

Additionally, the geometry of the bushing plays a crucial role in load resistance. Optimizing the thickness, radius, and taper of the bushings can significantly enhance their performance. For instance, bushings used in applications like cat back exhaust systems or performance brakes often require steeper tapers and enhanced radial rigidity to manage the dynamic forces involved. Integrating these design elements ensures that the polyurethane bushings maintain their structural integrity, providing reliable performance in demanding automotive environments, including those with intake components.

Applications and Benefits of Shape Retention in Polyurethane Components

Polyurethane components that retain their shape under heavy loads have found diverse applications across various industries. One notable use is in automotive parts such as muffler tips, brake rotors, and suspension kits, where their ability to withstand high pressure and stress without deforming is crucial for safety and performance. This characteristic makes polyurethane bushings a preferred choice for these critical components, ensuring they maintain their structural integrity even under extreme conditions.

The benefits of shape retention in polyurethane are multifaceted. Firstly, it enhances the overall durability of the parts, reducing the risk of failure or damage over time. Secondly, it improves the longevity and performance of vehicles and machinery by maintaining precise alignment and stability. Additionally, shape-retaining polyurethanes offer excellent vibration absorption properties, further contributing to a smoother ride and reduced noise levels. These advantages make them invaluable in industries demanding high-performance, long-lasting, and reliable components.

Polyurethane bushings that maintain shape under heavy load are a game-changer in various industries. By understanding the unique materials and properties of polyurethane, along with thoughtful design considerations, these bushings offer superior performance and benefits in numerous applications. Their ability to retain shape even under extreme pressure makes them a reliable choice for demanding environments, ensuring longevity and efficiency in everything from automotive components to industrial machinery.