Charge pipes, essential for high-performance engines, streamline air flow from turbochargers/superchargers to intake manifolds, reducing backpressure and enhancing performance. Strategically designed, they improve engine bay aesthetics, simplify maintenance, and highlight vehicle power. In tight spaces, engineers use CAD software to optimize pipe design for minimal turbulence and interference, with regular cleaning and airtight seals ensuring long-term efficiency.

Looking to optimize your engine’s performance in tight spaces? Discover the game-changing benefits of charge pipes, essential components that streamline airflow efficiently. This article delves into their crucial role, highlighting how they enhance engine power while fitting seamlessly into compact engine bays. We’ll explore design considerations and installation tips to ensure a clean, optimal fit. Unlock your engine’s potential with these innovative charge pipes.

- Understanding Charge Pipes: Their Role and Benefits

- Design Considerations for Tight Engine Bays

- Installation Tips: Achieving a Clean Fit

Understanding Charge Pipes: Their Role and Benefits

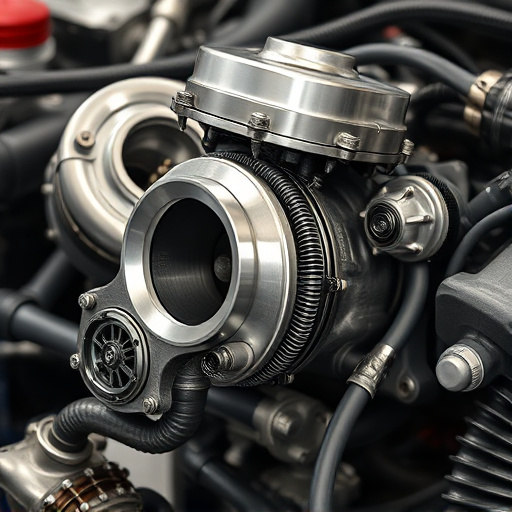

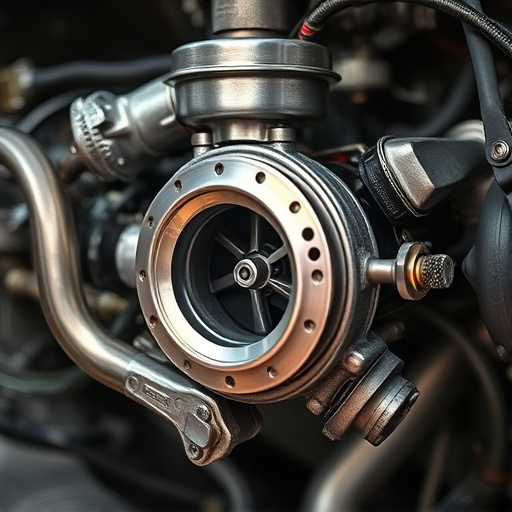

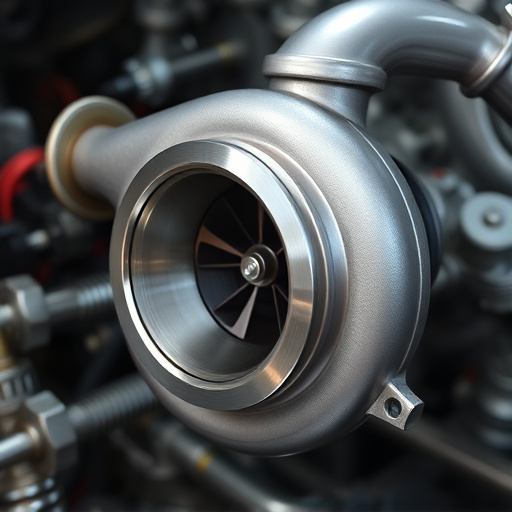

Charge pipes, an integral part of any high-performance engine setup, play a crucial role in enhancing the overall efficiency and power delivery of the vehicle. These components serve as the conduit for transporting compressed air from the turbocharger or supercharger directly to the intake manifold, ensuring a seamless flow of atmospheric pressure into the engine. By streamlining the process of delivering cool, dense air, charge pipes contribute significantly to improved engine performance, especially in scenarios where minimizing air restriction is paramount.

Beyond their functional benefits, well-designed charge pipes offer several advantages. They help reduce backpressure within the exhaust system, allowing gases to exit efficiently, which can lead to improved turbocharger or supercharger performance. Additionally, their strategic placement and seamless integration into the engine bay contribute to a cleaner, more organized appearance, contrasting with the often bulky and complex nature of intake components and muffler tips. This aesthetic appeal not only enhances the overall look of the vehicle but also facilitates easier maintenance and servicing of critical engine components.

Design Considerations for Tight Engine Bays

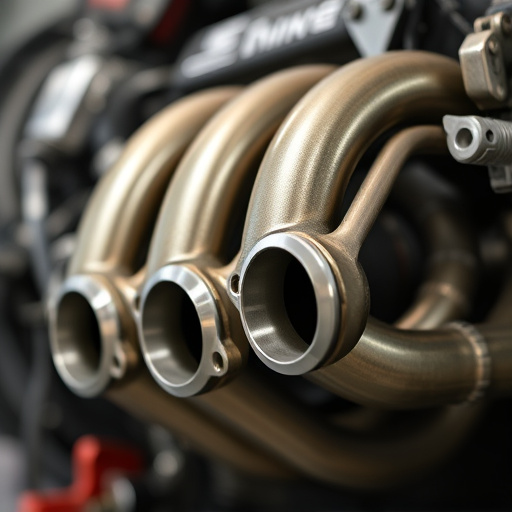

When designing charge pipes for tight engine bays, several factors come into play to ensure a clean fit and optimal performance. Engineers must consider the limited space available while incorporating features that enhance both airflow and cooling efficiency. The goal is to create a seamless integration that allows for proper air flow, minimizing turbulence and ensuring the charge pipes do not interfere with other components or systems in the bay.

One key consideration is the overall size and shape of the charge pipes, which should be tailored to fit the specific engine bay dimensions. Using advanced CAD software, designers can model and test various configurations to find the most efficient arrangement. Additionally, incorporating features like optimized bend radii, smooth internal surfaces, and strategic mounting points helps in reducing air resistance and ensuring the smooth flow of compressed air. Upgrading to high-performance air filters or air filter kits can also enhance overall engine performance, further emphasizing the importance of thoughtful design within these confined spaces.

Installation Tips: Achieving a Clean Fit

When installing charge pipes designed to fit snugly within tight engine bays, attention to detail is key to achieving a clean and efficient setup. Begin by ensuring all components are properly aligned; misalignment can lead to leaks and performance issues. Next, use high-quality sealants and gaskets to create an airtight connection between the charge pipes and surrounding parts, such as intake manifolds and headers. This step is crucial for maintaining optimal engine performance and minimizing backpressure.

For a seamless installation, consider the layout of your engine bay. Proper clearance around the exhaust components, including brake rotors and cat-back exhaust systems, ensures smooth airflow and prevents obstructions. Regular cleaning and inspection of the charge pipes and associated hardware can also help maintain their integrity over time, ensuring continued peak performance in your vehicle.

Charge pipes are a smart solution for maximizing engine performance in compact spaces. By understanding their role, considering design constraints of tight engine bays, and following installation best practices, you can ensure a clean fit that enhances your vehicle’s power and efficiency. This simple modification makes a big impact, allowing you to unlock the full potential of your engine with streamlined, high-performance charge pipes.