Custom DTF (Direct to Fabric) transfers offer a revolutionary, efficient printing solution for light fabrics, eliminating complex equipment. Designers create or source optimized artwork, which is transferred onto specialized ready-to-press films using advanced technology. Printers apply the design with heat press, achieving fast, cost-effective results. This method is popular among fashion designers, small businesses, and enthusiasts for swiftly bringing creative visions to life with precise cutting, strategic layout, and vibrant colors suitable for diverse dark fabric applications. Custom DTF transfers streamline processes, simplify application, and offer versatile uses in promotional merchandise, custom apparel, signages, and decorative items on various materials.

Discover the revolution in custom printing with Ready to Press DTF (Direct to Fabric) transfers. This innovative technology streamlines the process, allowing designers and businesses to effortlessly create high-quality, vibrant prints on various fabrics. In this guide, we’ll explore the intricacies of the custom DTF transfer process, from design and print considerations to its diverse applications. Uncover the benefits that make these ready-to-press transfers a game-changer for on-demand printing.

- Understanding Custom DTF Transfer Process

- Design and Print Considerations for DTF Transfers

- Benefits and Applications of Ready to Press DTF Transfers

Understanding Custom DTF Transfer Process

Custom DTF (Direct to Fabric) transfers are a cutting-edge printing solution designed to revolutionize the way we adorn our garments and textiles. This process involves a unique, ready-to-press transfer film that facilitates precise and vibrant printing on light fabrics. Unlike traditional methods, DTF transfers offer a straightforward approach to achieving high-quality designs without the need for elaborate equipment or complex techniques.

The custom DTF transfer process begins with designing or sourcing the artwork, ensuring it’s optimized for print. The graphic is then precisely transferred onto a specialized film using advanced printing technology. This film acts as a temporary carrier, allowing printers to easily apply the design to various light-colored fabrics with just a heat press. The result is a fast, efficient, and cost-effective method of creating custom printed materials, making it popular among fashion designers, small businesses, and enthusiasts looking to bring their creative visions to life swiftly and with remarkable detail.

Design and Print Considerations for DTF Transfers

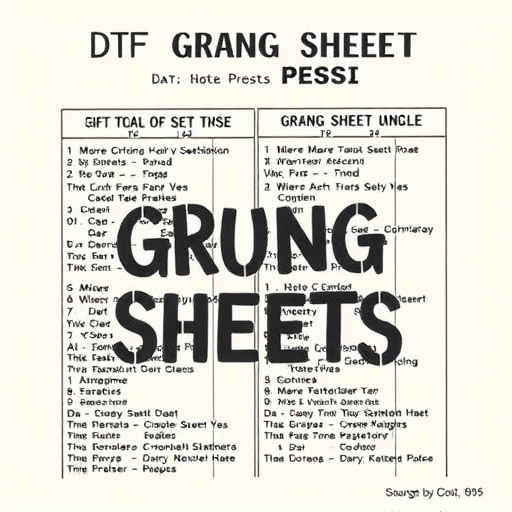

When it comes to Custom DTF Transfers Ready To Press, design and print considerations are paramount. Designers should opt for high-resolution graphics, ensuring every detail is crisp and vibrant when printed. The choice of colors matters too; for dark fabrics, dtf printing techniques require specific color profiles to achieve optimal results without fading or blotching. Using the right software that supports DTF transfer preparation is essential, as it allows precise cutting and positioning of designs.

Additionally, understanding the cold peel process of DTF transfers is crucial. This involves selecting materials that adhere well to fabrics while ensuring easy removal after printing. The design should be arranged with these factors in mind, considering elements like layout, font choices, and the overall aesthetic. With these considerations, creators can produce stunning, long-lasting DTF transfers suitable for a variety of dark fabric applications.

Benefits and Applications of Ready to Press DTF Transfers

Custom DTF (Direct-To-Film) transfers offer a host of benefits for businesses and creatives looking for efficient, high-quality printing solutions. These ready-to-press films streamline the production process by eliminating the need for complex set-up steps, reducing preparation time significantly. With pre-adhered backing, they are user-friendly, allowing designers to focus on their creative vision rather than technical intricacies.

The versatility of DTF transfers is evident in various applications. From promotional merchandise and custom apparel to signages and decorative items, these transfers can be used on a wide range of materials like fabric, plastic, wood, and metal. The direct-to-film printing method ensures vibrant colors and sharp details, making them ideal for creating eye-catching designs. Moreover, cold peel DTF transfers provide an easy-peel solution, simplifying the application process and ensuring a smooth finish on various surfaces.

Custom Ready to Press DTF (Direct to Fabric) transfers offer a streamlined solution for businesses looking to print on demand. By understanding the unique benefits of this process, from design considerations to enhanced application flexibility, you can leverage these transfers to create vibrant, high-quality custom garments and products with minimal effort. This efficient approach to printing ensures that your business stays competitive in today’s dynamic market.