Hydraulic suspension systems transform automotive performance and safety by using fluid pressure for height adjustment and control, enhancing stability in various conditions. However, without proper structural reinforcement, these systems face increased stress on vital components during high-performance driving, leading to potential structural failures and reduced efficiency. Thus, integrating reinforcement is crucial for optimal vehicle dynamics, crash safety, and the effective operation of hydraulic suspension technology.

Hydraulic suspension systems offer unparalleled ride quality, but their implementation demands careful structural reinforcement for safety. This article delves into the intricacies of these advanced systems, exploring the challenges and risks associated with unreinforced designs. We highlight the pivotal role of structural reinforcement in enhancing vehicle stability and passenger safety, underscoring its importance in modern automotive engineering. By understanding these key aspects, manufacturers can ensure the seamless integration of hydraulic suspension for superior performance and peace of mind.

- Understanding Hydraulic Suspension Systems

- Challenges and Risks of Unreinforced Implementation

- The Role of Structural Reinforcement in Safety Enhancement

Understanding Hydraulic Suspension Systems

Hydraulic suspension systems are a sophisticated engineering marvel that has transformed the automotive industry. These systems utilize fluid pressure to control and adjust the height and posture of vehicles, offering enhanced performance and comfort. By enabling precise control over vehicle dynamics, hydraulic suspension enhances stability, especially during aggressive driving maneuvers or on rough terrain. This technology is not limited to luxury vehicles; it’s also integral to off-road cars and trucks, where its ability to adapt to varying terrains is invaluable.

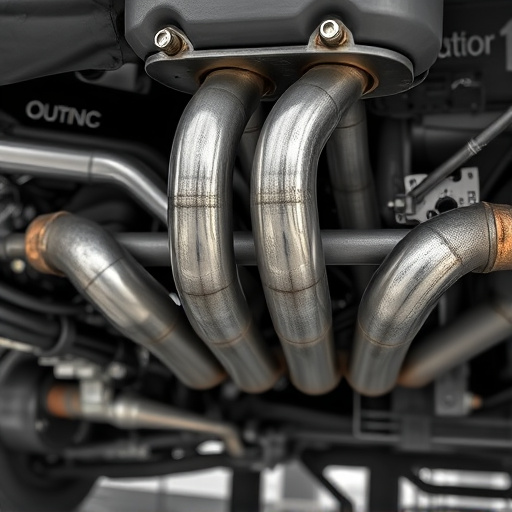

In addition to their performance benefits, hydraulic suspensions play a critical role in safety. The structural integrity of the vehicle depends on the suspension’s capacity to absorb and distribute impact forces evenly. When properly designed and reinforced, these systems can significantly reduce the risk of damage to essential components like exhaust mufflers and exhaust tips, ensuring optimal vehicle performance and rider safety. Moreover, advanced hydraulic suspensions can contribute to improved handling and reduced body roll, enhancing overall control, especially in high-performance vehicles equipped with powerful engines and tailored performance exhaust systems.

Challenges and Risks of Unreinforced Implementation

Implementing a hydraulic suspension system without proper structural reinforcement can pose several challenges and risks that often go overlooked. One of the primary concerns is the potential for increased stress on critical components, particularly during high-performance driving conditions. Hydraulic suspensions rely on fluid power to adjust height and cushioning, but this very mechanism can also lead to excessive strain if not supported adequately. Without reinforcement, routine braking maneuvers or abrupt steering inputs could cause structural failures in the suspension system, compromising both safety and vehicle control.

Moreover, unreinforced hydraulic suspensions may result in reduced effectiveness of performance brakes and other advanced brake components designed for optimized stopping power. The lack of structural integrity can also negatively impact the overall performance of high-performance air filters, which are crucial for maintaining engine efficiency. These issues underscore the importance of integrating structural reinforcement into any hydraulic suspension setup to ensure both safety and optimal vehicle dynamics.

The Role of Structural Reinforcement in Safety Enhancement

The incorporation of structural reinforcement is a vital aspect when enhancing safety in vehicles equipped with hydraulic suspension systems. These intricate mechanisms, while offering smooth and adaptable ride quality, also demand robust support structures to mitigate potential risks. The primary function of structural reinforcement lies in fortifying critical components, ensuring they withstand the forces exerted during operation, especially under extreme conditions. This includes reinforcing areas subject to stress, such as the connection points of suspension components, exhaust systems, and performance exhaust pipes.

By strengthening these areas, the overall stability and integrity of the vehicle are improved. This is particularly crucial in hydraulic suspension setups, where the system’s fluidity and control rely on a stable chassis and body structure. Adequate reinforcement prevents structural failure, enhances crash safety, and ensures that the advanced suspension technology performs optimally without compromising passenger security.

Implementing hydraulic suspension systems in vehicles requires careful structural reinforcement for optimal safety. As discussed, unreinforced integration can lead to severe challenges and risks, compromising both passenger security and vehicle integrity. By enhancing structural reinforcement, manufacturers can ensure the stability and durability of these advanced suspension setups, ultimately providing a safer driving experience. This is crucial for the ongoing development and adoption of hydraulic suspension technology in various automotive sectors.