Exhaust system shops address complex noise and vibration issues in modern cars through specialized knowledge and tools. They diagnose and mitigate problems from internal combustion, manifolds, converters, and mufflers. Upgrades like cold air intakes enhance performance harmony. Shops use sound-absorbing materials, sealed systems, and soundproofing barriers to reduce noise levels. Best practices prioritize safe, quiet operation, certified technicians, high-quality materials, and regular maintenance for customer satisfaction and regulatory compliance.

In the realm of automotive maintenance, exhaust system shops play a vital role in ensuring vehicle safety and performance. However, they also face unique challenges posed by noise and vibration from exhaust systems. This article delves into understanding these issues, exploring strategies to mitigate sound at exhaust shops, and highlighting best practices for quieter and safer vehicle operation. By implementing effective solutions, exhaust system shops can enhance their operations and contribute to a more peaceful environment.

- Understanding Noise and Vibration in Exhaust Systems

- Strategies for Mitigating Sound at Exhaust Shops

- Best Practices for Safe and Quiet Vehicle Operation

Understanding Noise and Vibration in Exhaust Systems

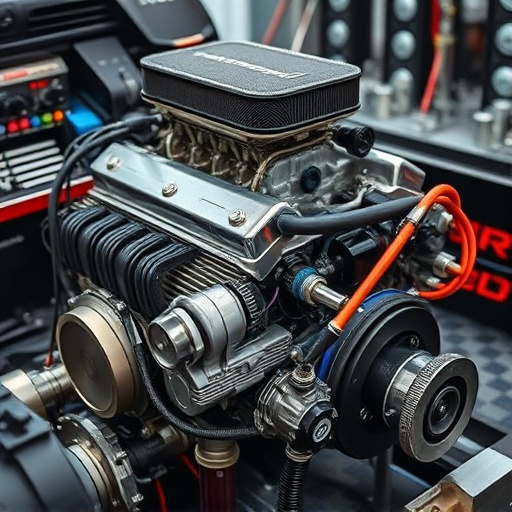

Noise and vibration in exhaust systems are multifaceted issues that significantly impact both performance and user experience. Exhaust system shops play a crucial role in addressing these challenges, especially as vehicles evolve with advancements in technology. In modern cars, various components interact to create complex noise patterns, from the engine’s internal combustion to the flow of gases through the exhaust manifold, catalytic converter, and muffler. Vibration, on the other hand, arises from the resonance of these components, often amplified by the system’s design and operating conditions.

At exhaust system shops, professionals utilize specialized knowledge and tools to diagnose and mitigate noise and vibration issues. They inspect components like headers, pipes, silencers, and mufflers for damage, wear, or misalignment, which can cause unwanted noises. Additionally, shops assess the condition of brake components, as their wear can lead to vibrations during driving. For performance enthusiasts, shops also cater to upgrades such as cold air intakes and high-flow performance air filters, ensuring these modifications contribute positively to overall vehicle harmony rather than introducing new noise or vibration problems.

Strategies for Mitigating Sound at Exhaust Shops

Exhaust system shops employ various strategies to mitigate sound levels within their premises, ensuring a safer and more comfortable working environment for employees and surrounding communities. One of the primary methods involves installing sound-absorbing materials on walls, ceilings, and floors. These materials, such as acoustic panels and foam, help reduce reflections and reverberation, minimizing echo and noise buildup. Additionally, using sealed and insulated exhaust systems plays a crucial role in noise reduction. This includes proper sealing of air intake systems and exhaust pipes to prevent leakage, which can significantly decrease overall noise levels.

Another approach is to incorporate sound-dampening barriers between work areas and public spaces. For instance, installing specialized doors or walls with built-in soundproofing technology can block out external noise from entering the shop while containing workshop noise from spreading outward. Moreover, regular maintenance of suspension components and intake components is essential. By keeping these parts in good condition, shops can minimize the vibration and subsequent noise associated with their operation, contributing to a quieter work environment.

Best Practices for Safe and Quiet Vehicle Operation

In any exhaust system shop, ensuring safe and quiet vehicle operation is paramount to maintaining a comfortable driving experience and adhering to noise pollution regulations. Best practices for achieving this involve several key strategies. Firstly, proper installation techniques are crucial; certified technicians should meticulously assemble exhaust components to minimize vibration during operation. This includes securing parts with the right hardware and aligning them correctly for seamless integration.

Additionally, employing high-quality materials and state-of-the-art equipment can significantly reduce noise levels. For instance, upgrading performance brakes or installing coilover kits can help refine vehicle dynamics, thereby lowering vibrations that cause excessive noise. Even simple upgrades like air filter kits can make a notable difference in engine sound reduction. Regular maintenance checks are also essential to identify and rectify any potential issues before they escalate, ensuring the exhaust system operates at optimal conditions, contributing to both safety and tranquility on the road.

Exhaust system shops play a vital role in addressing noise and vibration issues, ensuring quieter and safer vehicle operation. By implementing effective strategies, such as utilizing sound-absorbing materials, installing advanced silencers, and adopting best practices during service, these shops can significantly reduce exhaust noise. This not only contributes to a more comfortable riding experience for drivers but also adheres to environmental regulations. With the right approach, exhaust system shops can be the game changer in fostering quieter, greener transportation.