Intercooler piping design is crucial for high-performance vehicles, optimizing air flow to turbochargers/superchargers, reducing backpressure, and enhancing engine cooling efficiency. Strategic layout balances tube diameter, bend radii, and length for seamless airflow, minimizing heat absorption in the engine bay. Advanced techniques, including material selection and routing, contribute to improved intercooler system performance, boosting overall vehicle output and reliability.

Intercooler piping is a critical component in high-performance automotive systems, playing a pivotal role in efficient airflow control. This article delves into the intricacies of intercooler piping layout and design, exploring key factors influencing optimal performance. We discuss advanced techniques to enhance airflow management, ensuring your vehicle’s cooling system operates at peak efficiency. By understanding these aspects, you can achieve better engine performance and reliability.

- Understanding Intercooler Piping Layout and Design

- Key Factors Influencing Optimal Intercooler Piping

- Advanced Techniques for Efficient Airflow Management

Understanding Intercooler Piping Layout and Design

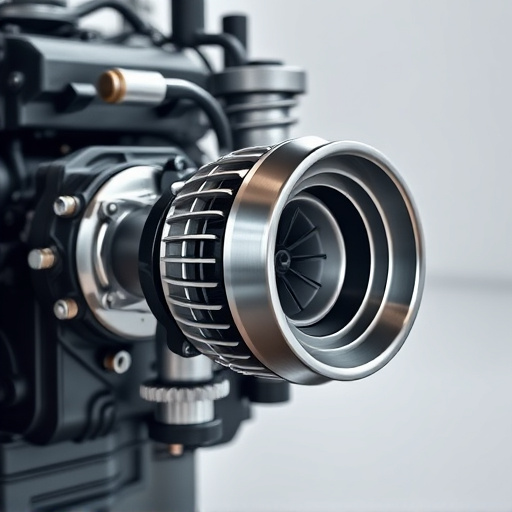

The intercooler piping layout and design are critical components in any vehicle’s cooling system, particularly for high-performance cars and trucks. This intricate network of tubes and connectors serves as the vital link between the engine and the intercooler, ensuring efficient airflow control. The primary goal is to optimize the flow of cool air into the turbocharger or supercharger, thereby enhancing engine performance and reducing overheating risks.

A well-designed intercooler piping system typically incorporates strategically placed muffler tips to minimize backpressure while allowing for smooth air circulation. By integrating these components seamlessly, engineers can achieve optimal vehicle performance, even with a cat back exhaust system in place. The layout should consider factors like tube diameter, bend radii, and the overall length of the pipes to guarantee efficient cooling without compromising on engine power.

Key Factors Influencing Optimal Intercooler Piping

The design and layout of intercooler piping play a significant role in determining the overall efficiency of an automotive cooling system. Several key factors come into play when optimizing intercooler piping for optimal airflow control. One crucial aspect is the material used; aluminum, for instance, is a preferred choice due to its excellent thermal conductivity, ensuring efficient heat transfer from the engine to the intercooler. The diameter and thickness of the pipes are also essential, as larger diameters allow for higher air flow rates without significant pressure drop, thereby enhancing cooling efficiency.

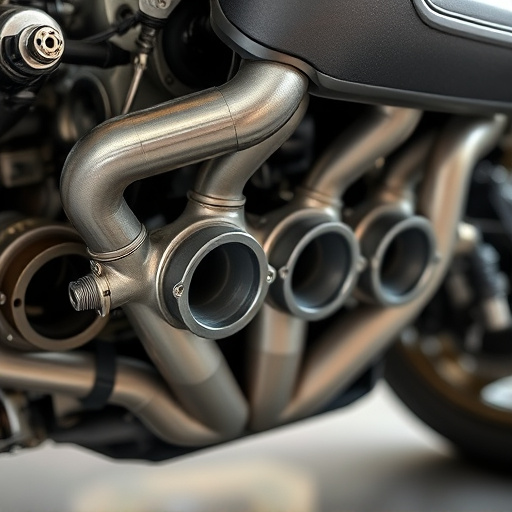

Additionally, strategic positioning of the intercooler within the engine bay, in relation to both intake components and brake components, is vital. Proper routing of the piping can minimize heat absorption from surrounding components, maintaining the cold air intakes’ integrity. This, combined with well-designed bends and curves, ensures a smooth airflow path, preventing turbulence that could reduce cooling performance. As such, careful consideration of these factors contributes to a more effective intercooler system, enhancing engine performance and reliability.

Advanced Techniques for Efficient Airflow Management

In the pursuit of optimal performance, advanced techniques for efficient airflow management are essential. Intercooler piping plays a pivotal role in this regard, allowing for precise control over air flow to and from the intercooler. By strategically designing and implementing high-flow intercooler piping systems, enthusiasts can experience significant gains in engine cooling efficiency. This, in turn, enhances overall engine output and response, particularly during demanding conditions like track days or off-road adventures.

Furthermore, integrating cold air intakes and suspension kits that complement the intercooler piping can further optimize airflow dynamics. For instance, a well-engineered cold air intake draws in cooler, denser air to fuel combustion, while a refined suspension kit reduces drag and optimizes ground clearance—both contributing to a smoother ride and improved engine performance. Even muffler tips, designed for reduced backpressure, play a supporting role in maintaining efficient airflow throughout the entire exhaust system.

Intercooler piping is a critical component in maintaining efficient airflow control within automotive systems. By understanding the layout, design, and key factors influencing optimal piping, vehicle performance can be significantly enhanced. Advanced techniques for managing airflow ensure optimized cooling, leading to improved engine durability and overall efficiency. Implementing these practices can revolutionize the way we approach intercooler management, making it a game-changer in today’s high-performance automotive landscape.