Direct-to-Film Transfers (DTF) revolutionize custom apparel production with cutting-edge technology, offering unparalleled versatility, streamlined production, and fast turnaround times while maintaining exceptional print quality on various fabric types. This modern method eliminates traditional printing methods, enabling high-resolution, vibrant prints with sharp details, meeting demanding customer expectations.

Direct-To-Film (DTF) transfers are transforming the custom apparel industry, offering a revolutionary approach to printing on demand. This article explores how DTF technology enables businesses to achieve vibrant, high-quality designs on a variety of fabrics with remarkable efficiency. We’ll delve into the benefits, applications, and implementation strategies, showcasing why DTF is becoming an indispensable tool for modern garment production.

- Understanding Direct-to-Film Transfers: A Custom Apparel Perspective

- Benefits and Applications in Modern Garment Production

- Implementing DTF for Efficient, High-Quality Customization

Understanding Direct-to-Film Transfers: A Custom Apparel Perspective

Direct-to-Film Transfers (DTF) represent a cutting-edge technology revolutionizing the custom apparel industry. This innovative process allows designers and businesses to create intricate, high-quality prints directly on fabric using specialized equipment. In the realm of custom apparel, DTF offers unparalleled versatility, especially for light fabrics like cotton or linen. By eliminating the need for traditional screen printing methods, it streamlines production, making it an attractive option for small batch orders or unique, one-off designs.

Understanding DTF from a custom apparel perspective involves grasping its ability to produce detailed, vibrant graphics with minimal setup time. The process involves applying a thin film of ink directly onto the fabric, which is then cured using heat or UV light. This method is particularly beneficial for dtf printing on t-shirts and other garments, ensuring fast turnaround times while maintaining exceptional print quality.

Benefits and Applications in Modern Garment Production

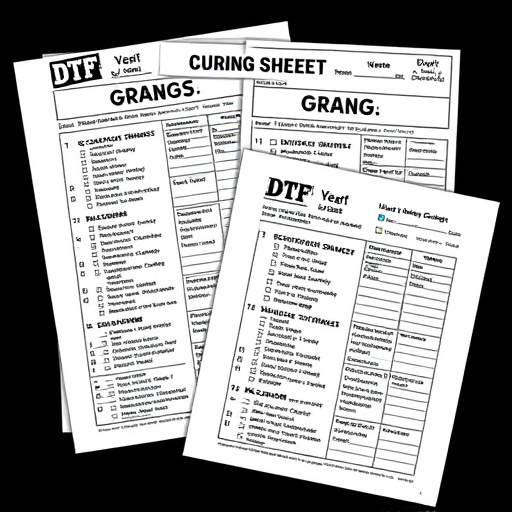

Direct-to-Film Transfers (DTF) have revolutionized modern garment production, offering numerous benefits to custom apparel businesses. One of the primary advantages is their ability to enable on-demand printing, allowing companies to create personalized, high-quality custom t shirts and other garments quickly and efficiently. DTF printers, unlike traditional heat press machines, can produce intricate designs with vibrant colors and fine details directly on various fabric types, making them versatile for a wide range of apparel.

Additionally, DTf transfer technology streamlines the production process by eliminating the need for separate printing and application stages. This not only reduces turnaround time but also minimizes waste, as the direct application ensures precise use of materials. The versatility of DTF further extends to its applicability across diverse fabric materials, from cotton and polyester to niche blends, ensuring that businesses can cater to a broader range of customer preferences and demands for custom apparel.

Implementing DTF for Efficient, High-Quality Customization

Implementing Direct-to-Film (DTF) technology for custom apparel production offers a significant advantage in terms of efficiency and quality. This innovative method streamlines the process of creating personalized designs on various garments, especially custom t-shirts, by eliminating the need for traditional screen printing or heat transfer methods. With DTF for t-shirts, businesses can achieve high-resolution prints with vibrant colors and sharp details directly onto the fabric.

The efficiency of DTF transfers lies in its quick setup and production time. Designers and businesses can easily prepare digital artwork and then use specialized equipment to apply the design directly onto the film, which is later pressed onto the garment. This modern approach ensures a swift turnaround, allowing custom t-shirt businesses to meet demanding customer expectations while maintaining exceptional print quality.

Direct-to-Film Transfers (DTF) have emerged as a game-changer in custom apparel production. By enabling efficient and high-quality printing directly onto fabrics, DTF offers businesses a competitive edge in meeting diverse customer demands. This technology streamlines garment customization processes, allowing for complex designs and fast turnaround times without compromising quality. As the demand for personalized clothing continues to rise, adopting DTF can empower custom apparel businesses to thrive in today’s market.