A turbocharger system boosts engine performance through forced induction, increasing power and torque while enhancing acceleration and efficiency. Modern systems use advanced technologies like VTG and ECUs for optimized speed and load performance. Upgrading exhaust systems complements these gains. Engineering for extreme conditions requires managing high temperatures, stress, and durability with specialized materials and cooling systems. Rigorous testing and optimization ensure reliability and peak performance under duress.

“Discover the ultimate performance booster, the turbocharger system, designed to conquer extreme driving conditions. This powerful technology has revolutionized automotive engineering, offering unprecedented speed and efficiency. In this article, we explore the intricacies of turbocharger systems, from their fundamental workings to the intricate process of engineering them for harsh environments. Unveiling the secrets behind testing and optimizing these systems ensures they deliver peak performance and reliability, making them a game-changer on and off the road.”

- Understanding Turbocharger Systems: Basics and Benefits

- Engineering for Extreme Conditions: Challenges and Solutions

- Testing and Optimization: Ensuring Performance and Reliability

Understanding Turbocharger Systems: Basics and Benefits

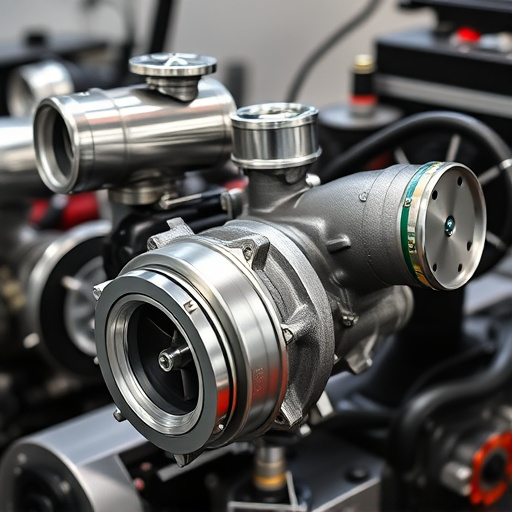

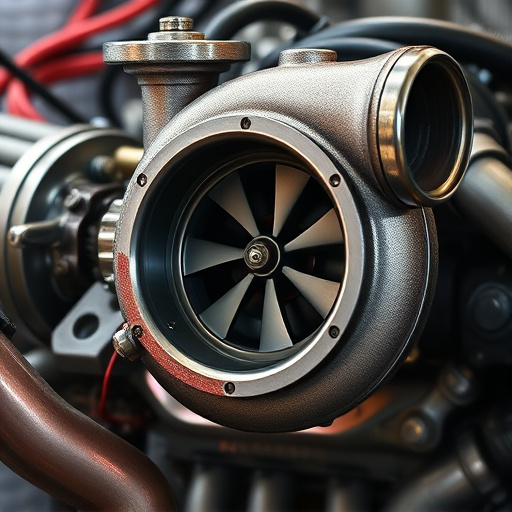

A turbocharger system is a powerful tool that enhances an engine’s performance by forcing more air into it. This forced induction method increases the power and torque output, leading to improved acceleration and overall engine efficiency. At its core, a turbocharger consists of two main components: a turbine and a compressor. The turbine spins from exhaust gases, which drives the compressor to pump in cold, dense air from the atmosphere. This additional oxygen allows the engine to burn fuel more efficiently, resulting in increased horsepower and a smoother power delivery.

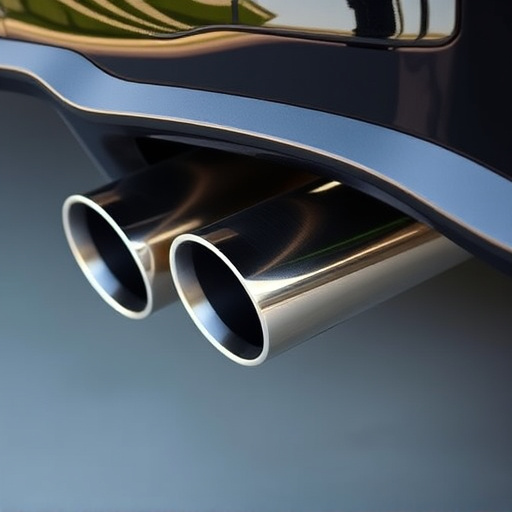

Understanding how a turbocharger system works is crucial when tackling extreme driving conditions. Unlike superchargers that are driven by the engine’s crankshaft, turbochargers utilize exhaust gas flow, making them lighter and more efficient. This design also allows for easier installation and integration into various vehicle architectures. Additionally, modern turbocharger systems feature advanced technologies like variable turbine geometry (VTG) and electronic control units (ECUs) to optimize performance across a wide range of speeds and loads. These features contribute to better fuel economy, reduced emissions, and enhanced drivability—even under demanding conditions such as high altitudes or extreme temperatures. Moreover, upgrading exhaust systems, including cat-back exhausts, can further complement the turbocharger’s capabilities by minimizing backpressure and optimizing gas flow.

Engineering for Extreme Conditions: Challenges and Solutions

Engineering a turbocharger system for extreme driving conditions presents unique challenges. These include managing elevated temperatures, sustaining performance under intense stress, and ensuring durability in harsh environments. One key solution involves employing advanced materials that can withstand high heat and pressure, such as specialized alloys and composites. Additionally, efficient cooling systems become imperative; liquid-cooled intercoolers and optimized oil circuits help maintain optimal operating temperatures.

Further challenges arise from varying atmospheric conditions, including altitude and humidity. To address these, engineers design turbocharger systems with variable boost controls that adapt to changing altitudes, ensuring consistent power delivery. Air filter kits, cold air intakes, and efficient breathing systems also play crucial roles in maximizing airflow, especially in humid regions where moisture can impact performance. These strategies combined enable the turbocharger system to perform optimally even under extreme driving conditions.

Testing and Optimization: Ensuring Performance and Reliability

Testing and optimization are crucial steps in developing a turbocharger system designed for extreme driving conditions. Engineers conduct rigorous simulations to mimic various environments, from steep inclines to rugged off-road trails, ensuring the system’s performance and reliability under duress. These tests involve pushing the turbocharger to its limits while monitoring critical parameters like boost pressure, temperature, and wear on components. By subjecting the system to extreme conditions, engineers can identify potential weaknesses and make necessary adjustments.

This process involves fine-tuning not just the turbocharger itself but also integrating it seamlessly with other high-performance parts, such as suspension kits and exhaust systems. The goal is to achieve a harmonious balance between power delivery, efficiency, and durability. Through iterative testing and optimization, the final product promises exceptional performance and dependable operation, even in the most challenging driving scenarios.

A well-engineered turbocharger system is essential for vehicles designed to handle extreme driving conditions. By understanding the fundamentals and benefits of these systems, addressing the unique challenges through innovative engineering, and rigorously testing and optimizing performance, manufacturers can deliver reliable and powerful vehicles capable of excelling in any environment. The turbocharger system emerges as a key enabler for navigating tough terrain, offering both efficiency and enhanced performance, ultimately elevating the driving experience to new heights.