Charge pipes, crucial for managing extreme temperatures in vehicles, rely on advanced alloys like nickel, chromium, and molybdenum for durability. Strategic design aims for uniform heat distribution, preventing local hot spots to ensure component stability. Optimal material selection and meticulous engineering are key to achieving peak performance and longevity under harsh conditions, benefiting high-performance sports cars, trucking, and industrial machinery.

“Charge pipes, essential components in high-performance systems, face the ultimate challenge: withstanding extreme temperatures. This article explores the innovative solutions revolutionizing the field. We delve into the material science behind these advanced charge pipes, revealing how engineering prowess creates durability in the harshest conditions.

From design strategies to state-of-the-art materials, we uncover the benefits and diverse applications of high-temperature charge pipes, shaping a future where performance is limited only by imagination.”

- Material Science Behind High-Temperature Charge Pipes

- Engineering Solutions for Extreme Heat Durability

- Applications and Benefits of Advanced Charge Pipes

Material Science Behind High-Temperature Charge Pipes

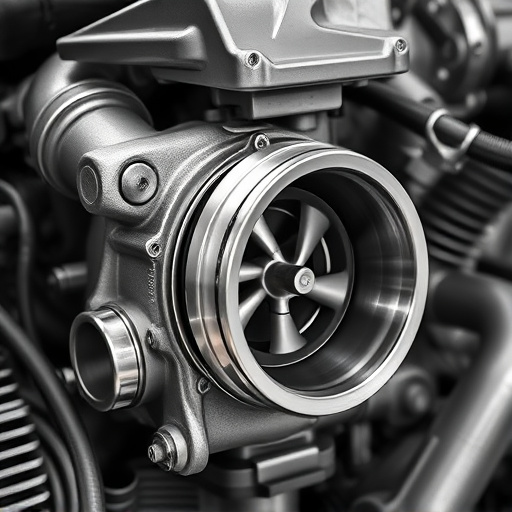

The material science behind high-temperature charge pipes revolves around selecting and designing materials that can withstand extreme conditions without compromising structural integrity or performance. These pipes are engineered to manage intense heat, often found in automotive applications like performance exhaust systems and cold air intakes, ensuring optimal engine performance. Advanced alloys, such as those incorporating nickel, chromium, and molybdenum, are frequently used for their superior heat resistance and corrosion protection properties.

Furthermore, the design considerations include efficient heat transfer to prevent local hot spots and ensure uniform temperature distribution along the pipe length. This is crucial not only for preventing thermal expansion issues but also for maintaining the structural stability of components adjacent to the charge pipes, such as brake pads in high-performance vehicles. The choice of materials and meticulous design play a pivotal role in achieving both exceptional performance and longevity under extreme temperatures.

Engineering Solutions for Extreme Heat Durability

In the pursuit of enhancing vehicle performance, engineering solutions for extreme heat durability are paramount, especially when it comes to charge pipes. These components play a crucial role in managing high temperatures, ensuring optimal functionality within various automotive systems. Advanced materials and innovative designs are being explored to create charge pipes that can withstand scorching conditions without compromise. By integrating robust alloys and specialized coatings, engineers aim to protect these pipes from the rigors of heat, preventing premature wear and tear.

Moreover, the focus on improving heat resistance extends beyond mere material choices. Engineering strategies also involve streamlining airflow around exhaust systems, which is particularly important in high-performance vehicles where intense heat is generated. This involves meticulous design considerations, such as strategic ventilation and advanced cooling mechanisms, to maintain charge pipe integrity throughout operation. Such tailored solutions not only guarantee the longevity of brake components but also contribute to overall vehicle reliability, especially under demanding conditions.

Applications and Benefits of Advanced Charge Pipes

Charge pipes, designed to withstand extreme temperatures, are not just a mechanical component but a crucial element in enhancing vehicle performance. Their primary applications span across various industries, from high-performance sports cars to heavy-duty trucking and industrial machinery. These advanced charge pipes offer numerous benefits that traditional exhaust mufflers cannot match. They ensure optimal air flow, reducing backpressure, which is vital for maximizing engine efficiency and power output.

Moreover, their temperature resistance makes them ideal for performance exhaust systems, especially in off-road vehicles and racing cars where extreme conditions are common. Unlike standard pipes susceptible to damage from heat, advanced charge pipes are built to last, often featuring durable materials and innovative designs that incorporate suspension kits for enhanced stability under stress. This technology not only improves engine cooling but also contributes to overall vehicle performance and safety.

Advanced charge pipes, engineered with innovative materials science and robust solutions, offer unparalleled durability even in extreme high temperatures. These cutting-edge components find applications across diverse industries, enhancing performance and reliability. By embracing these advanced technologies, professionals can harness the full potential of high-performance systems while ensuring longevity and safety under demanding conditions, solidifying the significance of charge pipes in modern engineering.