Strut tower braces, connecting suspension to chassis, enhance vehicle stability and handling by reducing body roll. Advanced materials like high-strength aluminum alloys or carbon fiber composites offer lightweight strength, corrosion resistance, and improved durability, integrating with modern components for better dynamics and efficiency. Optimal design involves strategic structural reinforcement, proper alignment, and material selection for reduced weight, enhanced handling, and corrosion prevention in diverse environments.

In the pursuit of enhanced vehicle performance, lightweight strut tower braces have emerged as a crucial component. This article delves into the essential functions and requirements of strut tower braces, exploring why they’re vital for stability and handling. We examine popular lightweight materials, including advanced composites and high-strength alloys, analyzing their unique properties. Additionally, design considerations are discussed to ensure optimal performance, durability, and safety in various driving conditions.

- Understanding Strut Tower Brace Functions and Requirements

- Exploring Popular Lightweight Materials for Strut Tower Braces

- Design Considerations for Optimal Performance and Durability

Understanding Strut Tower Brace Functions and Requirements

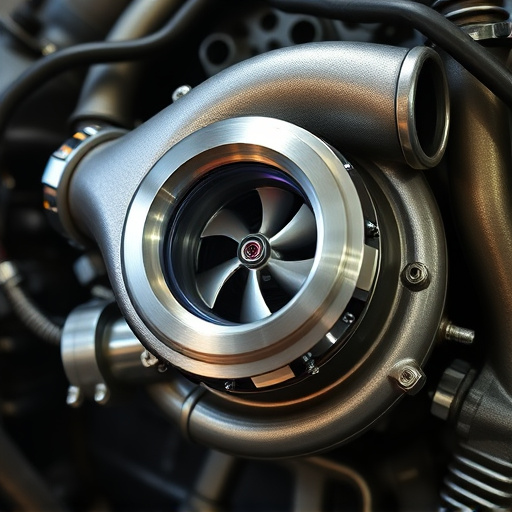

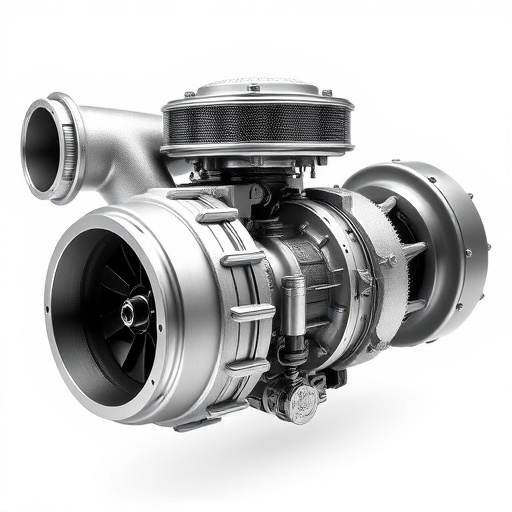

Strut tower braces are critical suspension components that play a pivotal role in enhancing vehicle stability and handling. Their primary function is to provide structural support by connecting the strut towers to the chassis, reducing body roll during cornering. This, in turn, improves overall vehicle dynamics and driver control. The effectiveness of a strut tower brace relies on its ability to withstand high torsional forces without compromising the integrity of other suspension components, such as air filter kits or air intake systems, which often share the same mounting points.

Understanding the specific requirements for a lightweight strut tower brace design is essential. This includes considering factors like material strength-to-weight ratio, corrosion resistance, and compatibility with existing suspension geometry. The use of advanced materials, like high-strength aluminum alloys or carbon fiber composites, allows for the creation of lighter, stiffer braces that can enhance vehicle performance without adding significant weight. These materials also ensure better heat dissipation, crucial for maintaining optimal operating temperatures in various driving conditions.

Exploring Popular Lightweight Materials for Strut Tower Braces

In the quest for enhanced vehicle performance and handling, the strut tower brace has emerged as a key component, connecting the suspension system to the vehicle’s chassis. When designing or upgrading strut tower braces, the choice of materials plays a pivotal role in achieving both lightweight construction and structural integrity. The automotive industry has witnessed a trend towards adopting popular lightweight materials for strut tower brace designs.

Among these, carbon fiber stands out due to its exceptional strength-to-weight ratio, making it ideal for high-performance vehicles. Aluminum alloys are another preferred choice, offering excellent corrosion resistance and lighter weight alternatives to traditional steel. Additionally, advanced composite materials, such as glass fiber-reinforced polymers (GFRP), provide a balance between strength and reduced weight, appealing to those seeking a more cost-effective yet durable solution. These materials not only contribute to improved vehicle dynamics but also enhance overall efficiency, particularly when integrated with modern exhaust tips, brake components, and air intake systems.

Design Considerations for Optimal Performance and Durability

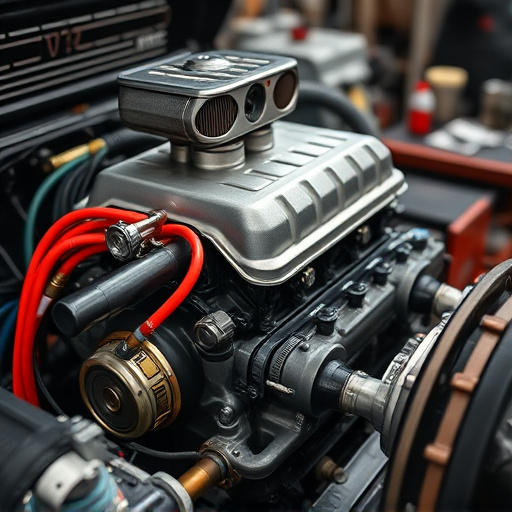

When designing a strut tower brace, prioritizing optimal performance and durability is paramount. Key considerations include material selection, structural integrity, and alignment precision. Using lightweight yet strong materials like high-grade aluminum or carbon fiber can significantly reduce weight, improving vehicle handling and response. These materials offer excellent strength-to-weight ratios, ensuring the strut tower brace effectively manages stress without adding excessive bulk.

Additionally, designers must account for factors such as corrosion resistance, especially in environments with high humidity or salt content, to prevent premature failure. Proper structural design, including strategically placed reinforcement ribs and mounting points, is crucial to withstand the lateral forces generated during cornering and braking. Ensuring proper alignment of the brace with the vehicle’s suspension components is also vital for maximizing its benefits, particularly when paired with performance upgrades like cold air intakes, air filter kits, or coilover kits.

When designing or selecting a lightweight strut tower brace, understanding the material’s role in enhancing vehicle performance is key. By considering the right mix of strength, weight reduction, and corrosion resistance, as discussed in this article, you can ensure your strut tower brace offers optimal durability and handling improvements for your automotive application. Remember that the best material choice ultimately depends on specific design requirements and desired performance levels.