DTF transfer processes for apparel require precise techniques to avoid common issues. Misalignment, ink bleeding, blocked nozzles, and pixelated prints can be prevented by verifying design file quality, fabric compatibility, machine calibration, and test printing on scrap pieces. Optimizing DTF printing involves using correct ink types, pressure settings, and software settings for high-quality results ready for pressing.

Experiencing issues with your DTF transfers ready to press? You’re not alone. Common problems can arise at various stages, from file preparation to printing. This comprehensive guide breaks down the fundamentals of DTF (Direct-To-Plate) transfer processes, identifies frequent challenges and their root causes, and provides proven troubleshooting strategies. By understanding these key aspects, you’ll enhance your print quality and streamline your workflow.

- Understanding DTF Transfer Basics

- Common Issues and Their Causes

- Effective Troubleshooting Strategies

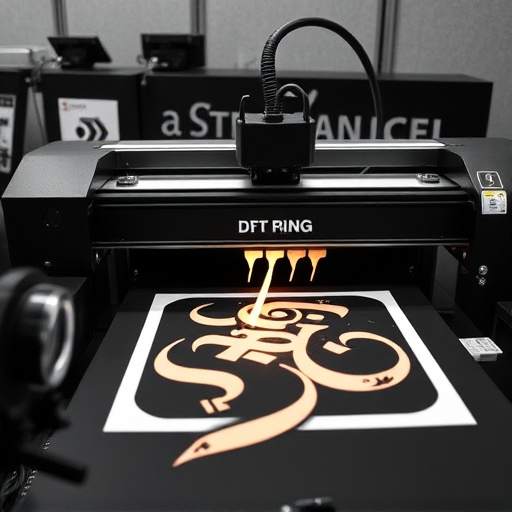

Understanding DTF Transfer Basics

A DTF (Direct to Fabric) transfer is a cutting-edge method revolutionizing the apparel industry, offering precise and intricate designs on various materials, especially light fabrics. This technique involves printing onto a special paper that serves as a temporary carrier for the design, which is then heatedly pressed onto the fabric, fusing the ink permanently. DTF for Apparel has become a game-changer, enabling businesses to create custom DTG transfers with remarkable detail and speed.

Understanding the fundamentals of DTF transfer ready to press processes is crucial for avoiding common issues. The key lies in preparation: ensuring the design is optimized for DTF printing, using high-quality materials, and following precise application techniques. For instance, when employing DTF printing for light fabrics, considerations like ink type and pressure settings become paramount to prevent smudging or inadequate transfer of the design.

Common Issues and Their Causes

Common DTF Transfer Ready to Press Issues often stem from a variety of factors. One prevalent problem is misalignment during the transfer process, leading to uneven or incomplete printing on the fabric. This typically results from improper positioning of the dtf transfer film or inconsistent application pressure. Another frequent challenge is ink bleeding, especially when dealing with custom dtf transfers designed for light fabrics. Inadequate drying time or using incompatible inks can cause this issue, affecting the clarity and durability of the final design.

Additionally, blocked nozzles in the printing head are a common hurdle, disrupting the smooth flow of ink during the DTF transfer ready to press stage. This can be attributed to dried-up ink, dust accumulation, or foreign particles within the machine. Proper maintenance, including regular cleaning and calibration, is crucial to mitigate such issues. Furthermore, improper settings in the printing software may lead to subpar results, causing colors to appear washed out or pixelated, especially when printing detailed designs for light fabrics using dtf transfer film.

Effective Troubleshooting Strategies

When encountering issues with a DTF (Direct to Fabric) transfer ready to press, effective troubleshooting strategies become paramount. Start by double-checking the quality and compatibility of your design files—corrupted or pixelated images can cause problems during the transfer process. Ensure your designs are in the correct format (like SVG or PNG) and resolution for the specific DTF machine you’re using. For logos dft for clothing brands and dtf for Custom graphic tees, precision is key; even slight misalignments can result in imperfect prints on the final products, especially when dealing with detailed artwork.

Inspect your fabric types and ensure they are suitable for DTF printing. Different fabrics have varying absorptivity levels, which can impact ink transfer. Using the wrong fabric, like a smooth or heavily woven material, might lead to smudging or incomplete ink application. Testing on scrap pieces of fabric before finalizing your order is a practical step, especially when working with dtf for t-shirts. Additionally, maintain and calibrate your DTF machine regularly, as faulty settings can cause misfires or misalignments, leading to subpar print quality.

When encountering issues with DTF transfers ready to press, understanding the fundamentals of the process and identifying common problems is key. By recognizing causes like improper file formats, resolution settings, or print driver conflicts, you can implement effective troubleshooting strategies. Regularly calibrating your equipment, updating firmware, and utilizing specialized software tools further ensure optimal DTF transfer results. With these steps, you’ll be well-equipped to address and prevent future challenges, guaranteeing high-quality prints every time.