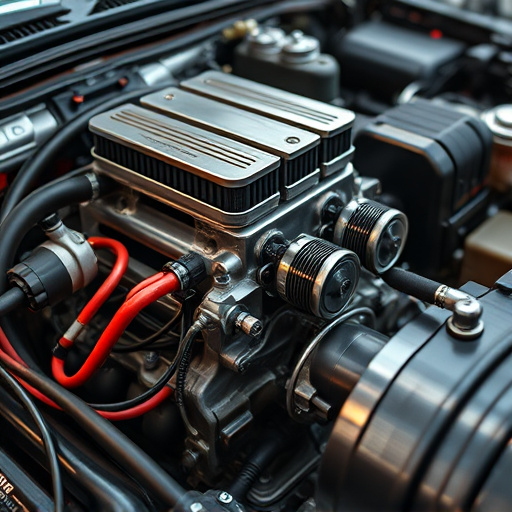

Understanding noise levels in quiet performance exhaust systems requires balancing gas flow, structural integrity, and noise control. Factors like engine type, power output, desired noise level, muffler design, and high-performance parts influence pipe diameter choices. Optimizing quietness involves measuring current noise levels, considering pipe length and diameter, selecting cat-back exhaust systems, evaluating air intake, and choosing quality brake rotors to minimize vibration.

Selecting the right pipe size for a quiet exhaust system involves balancing noise reduction with optimal engine performance. Understanding how sound travels through pipes and what factors influence their acoustic properties is key. This article guides you through the process, from deciphering noise levels to optimizing quiet performance. Learn essential steps to ensure your exhaust system offers both silent cruising and robust power delivery.

- Understanding Noise Levels in Exhaust Systems

- Factors Affecting Pipe Size Selection

- Optimizing Quiet Performance: A Step-by-Step Guide

Understanding Noise Levels in Exhaust Systems

Understanding Noise Levels in Exhaust Systems

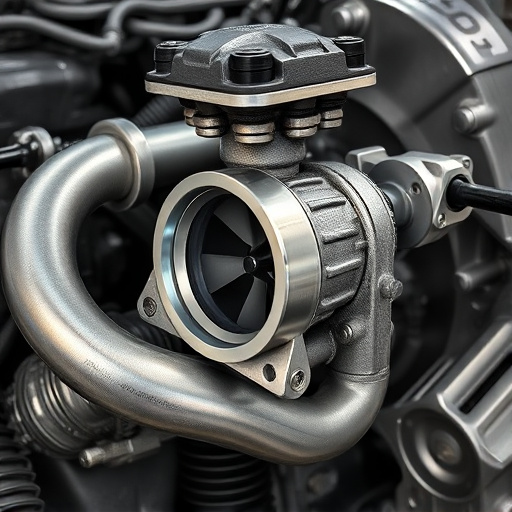

When it comes to quiet performance exhaust systems, noise level is a critical factor that influences both driver comfort and legal compliance. The primary source of noise in an exhaust system is the flow of gases—as air and fuel burn within the engine, they create vibrations that travel through various components, ultimately resulting in sound. Different materials, designs, and pipe sizes can significantly alter these sound waves, leading to variations in decibel levels.

In a well-designed quiet performance exhaust, the goal is to minimize noise without compromising vehicle performance or sacrificing structural integrity. This involves selecting appropriate pipe diameters that allow for smooth gas flow while dampening sound effectively. For instance, larger pipes can handle higher flow rates but may need additional muffling components to reduce noise levels, whereas smaller pipes might offer better noise control but could restrict airflow, impacting overall vehicle performance and potentially requiring modifications to cold air intakes or brake components.

Factors Affecting Pipe Size Selection

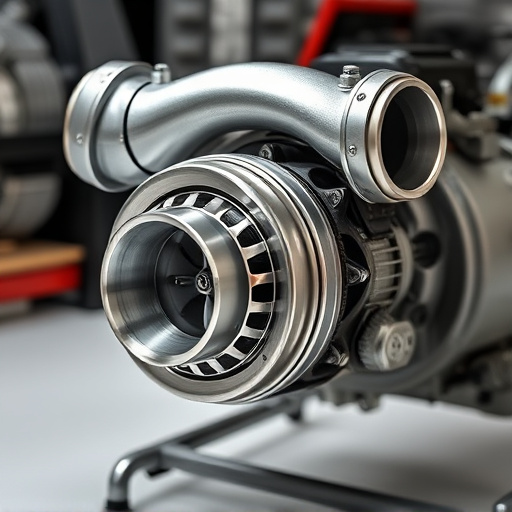

Selecting the appropriate pipe size for a quiet performance exhaust system involves considering several key factors. One of the primary considerations is the vehicle’s engine type and power output, as this directly influences the amount of exhaust gas produced and the necessary flow rate. Different engines require different pipe diameters to ensure efficient gas expulsion without compromising silence.

Additionally, the choice of pipe size is impacted by the desired level of quietness and the specific muffler tips or high-performance parts integrated into the system. To achieve a truly quiet ride, engineers must balance the need for smooth gas flow with noise reduction. Larger pipes can help in this regard, but they also require careful tuning to prevent backpressure, which could negatively affect engine performance. Suspension kits and other modifications should be taken into account as well, as they may introduce additional dynamic forces that the exhaust system needs to manage effectively.

Optimizing Quiet Performance: A Step-by-Step Guide

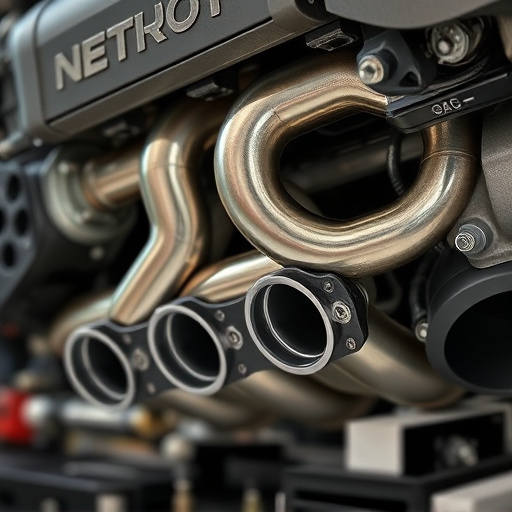

To optimize quiet performance in your exhaust system, follow this step-by-step guide. Firstly, assess the noise levels of your current setup using a decibel meter. This will give you a baseline to work from. Secondly, consider the length and diameter of your pipes; shorter, larger pipes tend to reduce noise by minimizing resonance and turbulence.

Next, choose a cat back exhaust system tailored for quiet performance, ensuring it’s designed to dampen sound effectively without compromising flow. Additionally, evaluate your air intake systems; a well-designed cold air intake can significantly contribute to overall quietness by delivering cool, dense air to the engine without creating unwanted noise. Remember that even your brake rotors can affect exhaust noise, so opt for high-quality rotors that are designed for reduced vibration and quiet operation.

When optimizing your quiet performance exhaust system, selecting the appropriate pipe size is crucial. By considering factors like vehicle type, engine specifications, and desired noise reduction levels, you can achieve a harmonious balance between efficient airflow and silent operation. Follow our step-by-step guide to ensure your exhaust system not only reduces noise but also enhances overall vehicle performance.