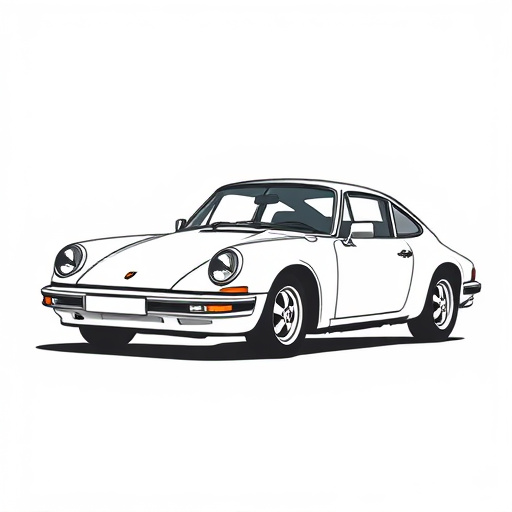

Ceramic coatings serve diverse purposes, from car protection to art preservation and window tinting. Selecting the right tools for application is vital for achieving flawless results in ceramic coating projects. Handheld applicators or spray guns are chosen based on detail vs. speed needs. Proper surface preparation enhances adhesion. Solvent selection considers environmental impact and safety. High-quality tools ensure better finish, longer durability, and reduced overspray. Regular maintenance keeps equipment optimal for ultimate project success.

“Unleash the potential of your vehicle with the transformative power of ceramic coating! This comprehensive guide navigates the essential steps in choosing the right tools for a flawless ceramic coating application. From understanding diverse coating types and their unique advantages to uncovering critical considerations, we demystify the process.

Learn expert tips on selecting equipment tailored for optimal results, ensuring a durable, sleek finish that protects your investment. Discover the secrets to achieving professional-level ceramic coating application.”

- Understanding Ceramic Coating Types and Their Uses

- Essential Considerations for Choosing the Right Tools

- Selecting Equipment: Tips for Optimal Application Results

Understanding Ceramic Coating Types and Their Uses

Ceramic coatings come in various types, each designed for specific applications and offering unique benefits when it comes to ceramic coating application. These advanced protective layers are renowned for their ability to safeguard surfaces from adverse weather conditions, UV rays, and scratches, enhancing both aesthetics and durability.

Understanding the difference between ceramic coatings is key to selecting the right one for your needs. For instance, some are ideal for vehicle protection, providing a durable barrier against road grime and bugs, while others excel in paint protection film applications, shielding paintwork from fading and chipping. Ceramic window tinting, another application, offers both privacy and UV filtering, making it popular for automotive and architectural uses. Each type has its own set of specifications, ensuring the right choice aligns perfectly with your desired outcome, be it protecting a car’s finish, preserving artwork, or enhancing window functionality.

Essential Considerations for Choosing the Right Tools

When it comes to achieving a flawless ceramic coating application, selecting the appropriate tools is paramount to success. The right equipment can streamline the process, ensuring precision and long-lasting results for custom graphics or vehicle wraps. One of the primary considerations is the type of applicator; traditional spray guns or more advanced airbrushes can be chosen based on the desired level of detail and finish. For intricate designs, an airbrush might be preferable due to its fine control, while spray guns offer faster application for larger areas, such as vehicle protection coatings.

Moreover, the surface preparation is another critical aspect. Adequate tools for sanding, cleaning, and degreasing are essential to ensure the ceramic coating adheres properly. The choice of solvents or cleaners should also be guided by the specific requirements of the coating manufacturer, considering factors like environmental impact and user safety, especially when dealing with vehicle protection products. Proper tool selection not only enhances the aesthetics but also contributes to the longevity and durability of custom graphics or protective layers.

Selecting Equipment: Tips for Optimal Application Results

Selecting the right equipment is paramount to achieving optimal results in ceramic coating application, whether for a custom vehicle wrap or professional PPF (Paint Protection Film) installation. The first step involves understanding your project’s unique needs and scope. For instance, while a small, intricate detail may require a more precise, handheld applicator, larger surfaces often demand a spray gun for even coverage. Consider the type of coating you’re using; some formulations are better suited to specific application methods.

Next, invest in high-quality tools designed for ceramic coatings, as these can significantly impact adhesion, sheen, and longevity of the finish. Look for applicators with microfibers or specialized nozzles that ensure precise control and minimize overspray, a common issue that can lead to inconsistent protection for your vehicle’s surface. Regular maintenance of your equipment is also crucial; keeping them clean and well-maintained ensures optimal performance throughout your project, providing the ultimate in vehicle protection.

When it comes to mastering the art of ceramic coating application, selecting the right tools is a game-changer. By understanding different coating types and their applications, along with considering key factors like surface preparation and environmental conditions, you can make informed decisions. Choose your equipment wisely, ensuring optimal results that enhance durability and protect your surfaces. With the right tools at hand, achieving professional-grade ceramic coating application becomes an achievable goal.