Mandrel-bent tubing is a key component in performance exhaust systems, optimizing gas flow and boosting engine power through precise curves while preserving integrity. Its customizable designs enhance exhaust dynamics, reducing restrictions for smoother gas movement and improving vehicle acceleration. This method maintains tube strength, handles high temps/pressures, pairs with upgraded parts, and offers quieter power delivery. Installation requires precision alignment; regular maintenance, inspections, gasket/clamp replacement, and cleaning ensure longevity and aesthetic appeal.

Mandrel-bent tubing, a key component in high-performance exhaust systems, enhances engine output and efficiency. This article delves into the fundamentals of mandrel-bent tubing, highlighting its benefits for improved flow and power in performance exhaust systems. We explore installation intricacies and maintenance tips, offering insights to ensure optimal performance and longevity. By understanding this technology, automotive enthusiasts can unlock their vehicles’ true potential, achieving a seamless blend of power and reliability in their performance exhaust system.

- Understanding Mandrel-Bent Tubing Basics

- Benefits for Performance Exhaust Systems

- Installation and Maintenance Considerations

Understanding Mandrel-Bent Tubing Basics

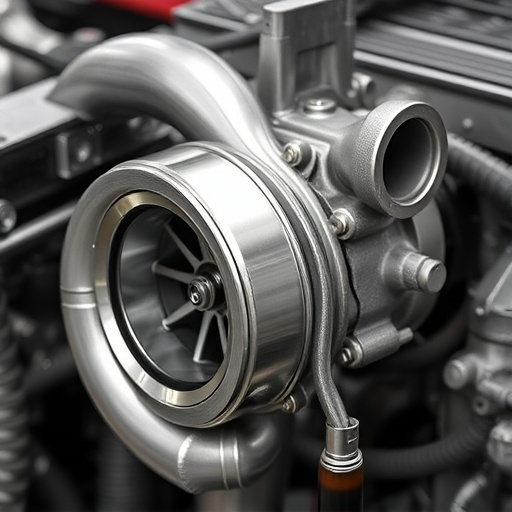

Mandrel-bent tubing is a critical component in high-performance exhaust systems, known for its role in optimizing gas flow and boosting engine power. This technique involves bending pipes using a mandrel, a tool that allows for precise, smooth curves while preserving the integrity of the tube’s internal diameter. The process enhances exhaust gas dynamics by reducing restrictions, enabling smoother and faster movement of gases from the engine. This is particularly beneficial in performance exhaust systems, where efficient flow can significantly impact engine performance.

In contrast to other bending methods, mandrel bending preserves the tube’s strength and structural integrity, ensuring it can withstand high temperatures and pressures encountered in performance applications. Additionally, the technique allows for custom designs, catering to specific vehicle requirements. Often paired with high-performance suspension kits and upgraded muffler tips or exhaust mufflers, mandrel-bent tubing contributes to overall system efficiency, enhancing acceleration and power delivery.

Benefits for Performance Exhaust Systems

Mandrel-bent tubing plays a pivotal role in enhancing the performance of exhaust systems, offering several advantages for vehicle performance enthusiasts. One of its key benefits is improved airflow efficiency. The precise bending process allows for tailored curves, ensuring optimal flow of gases, which can lead to increased engine power and torque. This is particularly crucial for high-performance vehicles where every component contributes to overall vehicle dynamics.

Additionally, mandrel bends provide a smoother transition within the exhaust system, reducing turbulence. This feature is beneficial for several reasons: it minimizes backpressure in the combustion chamber, allowing engines to operate more efficiently; it also reduces noise levels, providing a quieter yet powerful performance exhaust experience. Moreover, the ability to customize the tubing’s shape and size makes mandrel-bent tubing versatile, accommodating various vehicle setups and enhancing cold air intakes for optimal engine cooling.

Installation and Maintenance Considerations

When installing a mandrel-bent tubing in a performance exhaust system, precision is key. The intricate design of these tubes requires careful alignment and secure fastening to ensure optimal gas flow. Improper installation can lead to restrictions, power loss, and even potential safety hazards. Professional mechanics often use specialized tools and techniques to guarantee a seamless fit, enhancing the overall performance of the vehicle’s exhaust system.

Regular maintenance is equally vital for longevity. Mandrel-bent tubes are susceptible to corrosion over time due to exposure to varying temperatures and road conditions. Routine inspections should include checking for signs of damage, wear, or rust, especially at joints and connections. Replacing worn components, such as gaskets and clamps, and cleaning the tubes periodically will ensure the performance exhaust system maintains its efficiency and aesthetic appeal, featuring pristine exhaust tips that enhance the vehicle’s overall look.

Mandrel-bent tubing is a key component in high-performance exhaust systems, offering benefits such as improved airflow, increased throttle response, and enhanced engine sound. By understanding its basic principles and installation considerations, car enthusiasts can harness the full potential of their vehicles’ engines. Incorporating mandrel-bent tubing into a performance exhaust system is a strategic move that contributes to a smoother, more enjoyable driving experience.