Exhaust cutout valves are key automotive components that manage airflow, optimizing performance and fuel efficiency based on driving conditions. High-performance vehicles integrate them into suspension for dynamic control during aggressive maneuvers. Selecting the right valves requires considering both performance needs and application requirements to enhance engine performance, ensure seamless system operation, and prevent safety issues. Accurate measurement of exhaust system dimensions is crucial for precise fitment and maximizing vehicle performance.

Selecting the perfect size for your exhaust cutout valves is a critical step in any automotive build. These valves control engine exhaust flow, enhancing performance and allowing for custom tuning. This article guides you through the process of understanding exhaust cutout valves, factoring in key considerations like vehicle type and desired sound profile, and ensuring a precise fit for optimal engine performance. Learn how to make informed decisions when choosing these essential components.

- Understanding Exhaust Cutout Valves and Their Function

- Key Factors to Consider When Choosing Valve Sizes

- How to Ensure Proper Fit and Optimize Engine Performance

Understanding Exhaust Cutout Valves and Their Function

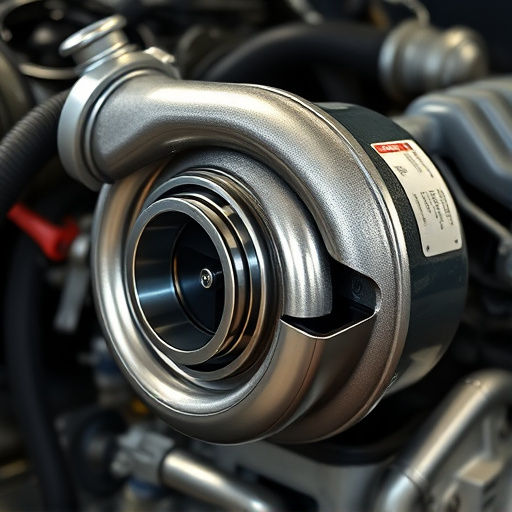

Exhaust cutout valves play a crucial role in managing airflow within an automotive system. These valves are strategically placed to control the flow of exhaust gases, allowing for precise tuning and performance optimization. Their primary function is to regulate the pressure and flow of exhaust gases, which can be adjusted based on vehicle speed, engine load, and other driving conditions. By manipulating these valves, engineers can fine-tune an automotive setup for enhanced performance, improved fuel efficiency, or specific racing requirements.

In many high-performance vehicles, exhaust cutout valves are integrated into coilover kits or suspension components. This allows for dynamic control over the exhaust system’s behavior, especially during aggressive driving maneuvers. When paired with advanced brake rotors and tailored coilover settings, these valves contribute to improved handling, reduced weight transfer, and enhanced overall driving dynamics. Understanding how exhaust cutout valves interact with other vehicle systems is essential for achieving optimal performance and fine-tuning a build to suit specific needs or racing disciplines.

Key Factors to Consider When Choosing Valve Sizes

When selecting exhaust cutout valves for your build, several key factors come into play. Firstly, consider the overall performance requirements of your vehicle or machine. Exhaust cutout valves are integral to enhancing engine performance by enabling efficient gas flow and optimized air intake systems. The right valve size ensures that your system operates seamlessly, allowing for quick exhaust release and improved turbocharger or supercharger functionality if applicable.

Additionally, think about the specific application and the kind of exhaust cutout valves needed. Different vehicles have varying engine sizes and configurations, which influence the required valve dimensions. Moreover, the interaction between the valves and performance air filters or intake components is crucial; they must work in harmony to maximize airflow without compromising efficiency or safety.

How to Ensure Proper Fit and Optimize Engine Performance

To ensure proper fit and optimize engine performance with exhaust cutout valves, start by measuring your vehicle’s exhaust system dimensions accurately. This includes the diameter, height, and depth of the cutout area where the valve will be installed. These measurements are crucial for selecting a valve that perfectly aligns with your vehicle’s specifications, preventing any gaps or misalignments.

Additionally, consider the impact of exhaust cutout valves on overall vehicle performance. By strategically placing these valves, you can enhance power delivery and torque output, especially in performance-oriented vehicles. Just as important is ensuring smooth airflow through the system, which can be achieved by choosing valves that are compatible with your coilover kits or other tuning modifications. Proper fitment not only guarantees reliable operation but also contributes to a more responsive and enjoyable driving experience.

When selecting the appropriate size of exhaust cutout valves, understanding their function and considering key factors like vehicle compatibility, expected usage patterns, and desired sound levels is paramount. By optimizing engine performance through precise valve sizing, you not only enhance overall vehicle dynamics but also ensure a seamless integration that contributes to both efficiency and aesthetics in your build.