Heavy-duty vehicles demand robust car suspension parts capable of withstanding extreme forces and conditions. Key considerations include enhancing shock absorbers, springs, axle assemblies, mounting systems, and damping mechanisms for longevity and stability. Heat, pressure, and debris tolerance in brake rotors, exhaust mufflers, and air filter kits minimize maintenance needs. Advanced technologies like adjustable suspension systems and optimized intake, cooling, and exhaust systems further enhance performance and durability. Rigorous testing and quality control guarantee car suspension parts meet high standards for safe, efficient operation over extended periods.

In the realm of automotive engineering, heavy-duty vehicles demand robust car suspension parts to withstand rigorous workloads. This article delves into the critical components and innovative designs that ensure durability in demanding environments. Understanding the unique challenges faced by these vehicles is key. We explore how specialized car suspension parts can enhance performance, safety, and longevity, making them indispensable for various industries. From advanced materials to rigorous testing, discover the secrets behind reliable heavy-duty suspensions.

- Understanding Heavy-Duty Suspension Requirements

- Key Components for Enhanced Durability

- Testing and Quality Assurance for Longevity

Understanding Heavy-Duty Suspension Requirements

Heavy-duty vehicles face unique challenges on the road compared to their lighter counterparts, demanding a robust and reliable car suspension system. Understanding the specific requirements for heavy-duty suspension parts is crucial for ensuring safety and performance over extended periods. These vehicles often operate under significant weight loads, navigate through challenging terrains, and are subjected to frequent stop-and-go movements, putting immense strain on various components. As such, car suspension parts designed for this sector must be engineered to withstand extreme forces and maintain stability under adverse conditions.

Key considerations include enhancing the strength and durability of shock absorbers and springs to absorb road shocks effectively. Additionally, robust axle assemblies, sturdy mounting systems, and improved damping mechanisms are essential to prevent premature wear and tear. Even components like brake rotors, exhaust mufflers, and air filter kits should be designed with heavy-duty applications in mind, ensuring they can tolerate higher heat, pressure, and debris without compromising performance or requiring frequent replacements.

Key Components for Enhanced Durability

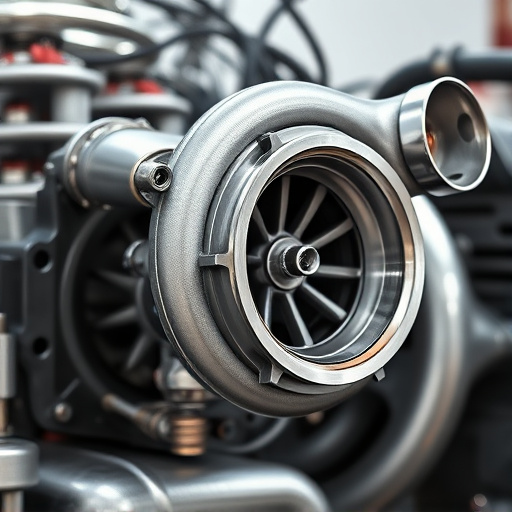

In the realm of heavy-duty vehicles, where power and performance are paramount, the reliability of car suspension parts becomes an indispensable factor for durability. Key components such as struts, shocks, and coil springs play a crucial role in ensuring the vehicle maintains optimal stability and control, even under extreme loads. These suspension components are designed to withstand rigorous conditions, from navigating challenging terrains to carrying heavy cargo, thereby extending the life of the entire system.

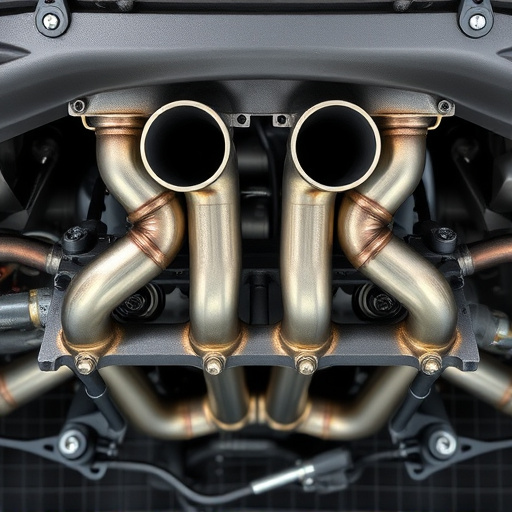

Moreover, advanced technologies like adjustable suspension systems offer an added advantage. These systems allow for fine-tuning, enabling drivers to adapt to different road conditions and driving styles. Additionally, integrating air intake systems and efficient cooling mechanisms can further enhance performance and durability by ensuring optimal engine operation, which indirectly benefits the overall health of car suspension parts, especially when coupled with a well-designed cat back exhaust system.

Testing and Quality Assurance for Longevity

In the realm of car suspension parts designed for heavy-duty use and durability, testing and quality assurance are paramount. Rigorous testing protocols ensure that each component endures a battery of simulations designed to mimic real-world conditions, from harsh weather to extreme terrain. This meticulous approach ensures that suspension kits and their various suspension components stand up to the demands of demanding applications.

Manufacturers employ advanced techniques and technologies to verify performance, safety, and longevity. High-tech equipment measures wear and tear, while sophisticated software models predict component life spans under different scenarios. Even exhaust tips, though seemingly unrelated, are subject to rigorous testing to ensure they withstand high temperatures and corrosive elements without compromising structural integrity or emitting harmful substances.

Car suspension parts designed for heavy-duty applications require a unique blend of robust materials, meticulous engineering, and rigorous testing. By understanding the specific demands of such vehicles, manufacturers can develop components that ensure longevity, safety, and superior performance. Key components like shock absorbers, springs, and control arms, when crafted with durability in mind, play a pivotal role in navigating challenging terrains and extreme conditions, ultimately contributing to a smoother ride and extended vehicle lifespan.