The design of an engine intake system directly impacts both the performance and sound of internal combustion engines. By meticulously crafting air passage shapes, lengths, vent placements, and incorporating sound-dampening materials, engineers can optimize airflow for enhanced power output while refining the engine's acoustic signature. This process not only reduces noise pollution but also improves vehicle tuning and customization through components like air filters, tubes, and manifolds, offering a smoother, quieter driving experience.

The design of an engine intake system plays a pivotal role in shaping the characteristic sounds produced by an internal combustion engine. This article delves into the intricate relationship between intake design, airflow patterns, and engine noise. We explore how specific intake configurations contribute to both undesirable noises and optimal performance. By understanding these dynamics, engineers can optimize intake systems for reduced sound emissions while enhancing overall engine efficiency.

- Intake Design's Role in Engine Sound Creation

- Impact of Airflow Patterns on Engine Noise

- Optimizing Intake for Reduced and Refined Sounds

Intake Design's Role in Engine Sound Creation

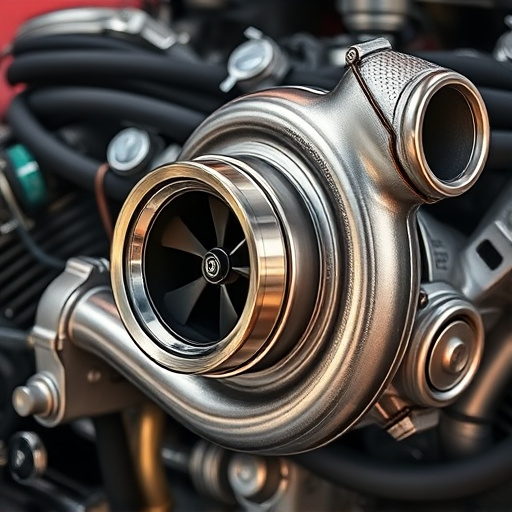

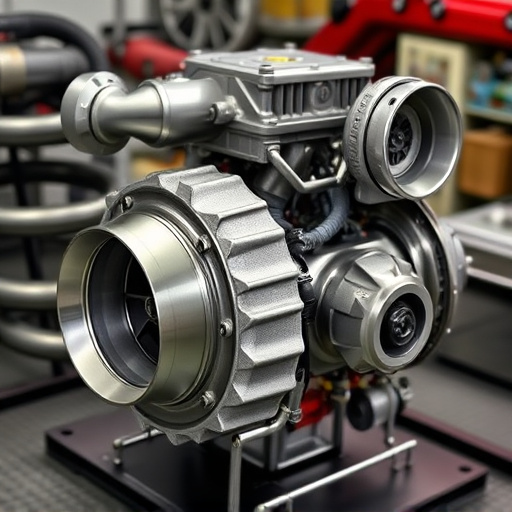

The design of an engine intake system plays a pivotal role in shaping the sound produced by the engine. The intake system is responsible for drawing air into the engine, and its components can significantly influence the airflow and pressure within the engine compartment. As air flows through the intake, it interacts with various parts such as air filters, tubes, and manifolds, each contributing to the overall acoustic experience.

A well-designed intake system can enhance performance brakes and optimize power output, but it also affects the sound signature. The shape, size, and materials used in the intake design can modify the sound waves generated during combustion, resulting in a deeper rumble or a more aggressive roar. For enthusiasts who appreciate the auditory feedback of their engine’s capabilities, customizing intake systems with coilover kits is a popular way to achieve a desired sound profile, adding to the overall driving experience.

Impact of Airflow Patterns on Engine Noise

The design of an engine intake system plays a pivotal role in shaping the overall noise profile of an internal combustion engine. Airflow patterns within the intake manifold can create complex sound waves that interact with various components, leading to both desirable and undesirable noises. Turbulent air flow, for instance, can generate a deeper, more robust exhaust note, often sought after by automotive enthusiasts. Conversely, smooth and laminar airflow might produce a quieter engine sound, which is generally preferred in urban environments to minimize noise pollution.

Engineers meticulously craft intake systems considering these airflow dynamics to achieve optimal performance and refine the engine’s acoustic signature. This involves strategic design choices such as the shape and length of air passages, the placement of vents, and even the integration of sound-dampening materials. Enhancing the airflow can also positively impact the engine’s power output and efficiency, making it a crucial aspect to consider when tuning or modifying vehicles, alongside other essential components like exhaust systems and air filter kits.

Optimizing Intake for Reduced and Refined Sounds

Optimizing the engine intake system is a delicate art that can significantly refine and reduce unwanted noise. By carefully designing the intake components, engineers can create a smoother flow of air into the engine, minimizing turbulence and the subsequent vibrations that cause loud noises. This process involves selecting the right materials and shapes for the air filter housing, mass airflow sensors, and the intake pipe itself to ensure a consistent and controlled air delivery.

Using high-performance parts like advanced performance air filters can play a crucial role in this optimization. These filters are designed to allow optimal airflow while capturing fine particles, preventing air leaks, and reducing turbulence. Additionally, incorporating suspension kits that provide precise control over the vehicle’s motion can indirectly contribute to quieter operation by minimizing shock absorption adjustments required during engine operation, further refining the overall sound profile.

The design of an engine intake system plays a pivotal role in shaping the overall sound of an internal combustion engine. By understanding airflow patterns and optimizing intake components, engineers can significantly impact noise reduction and create refined engines. Through precise tuning and innovative designs, modern engine intake systems are revolutionizing both performance and acoustic experiences, ensuring quieter, more enjoyable driving for folks across various landscapes.