Turbocharger systems enhance engine performance and efficiency in off-roaders and sports cars by compressing air for better fuel burning and power output. Key components include turbine, compressor, and intercooler. Extreme driving conditions demand robust materials, cooling mechanisms, and sealing to withstand high temperatures (up to 260°C) and pressures exceeding 30 psi. Regular maintenance is crucial. Innovations in air filters, intake systems, specialized materials, and cooling mechanisms improve performance under harsh environments, with durable, lightweight components enhancing system reliability.

In the realm of automotive engineering, the turbocharger system stands as a marvel of modern technology, enhancing engine performance while improving fuel efficiency. However, pushing these systems to their limits in extreme driving conditions presents unique challenges. This article delves into the intricate world of turbochargers, exploring their fundamental principles and components. We examine the hurdles posed by intense heat, pressure, and durability demands, and uncover innovative engineering solutions that elevate turbocharger performance in harsh environments.

- Understanding Turbocharger Systems: Principles and Components

- Challenges in Extreme Driving Conditions: Heat, Pressure, and Durability

- Engineering Solutions: Enhancing Turbocharger Performance in Harsh Environments

Understanding Turbocharger Systems: Principles and Components

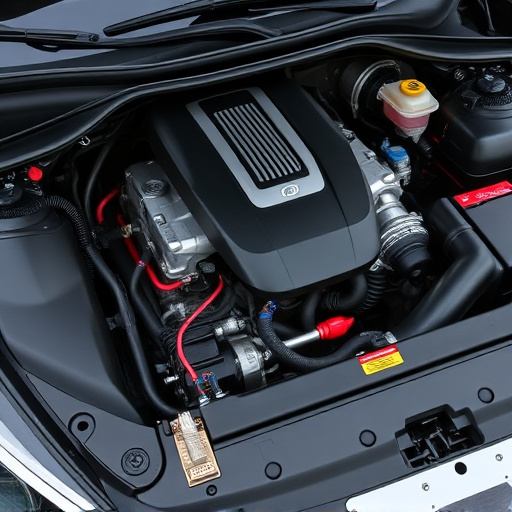

A turbocharger system is a powerful tool that enhances the performance and efficiency of an internal combustion engine. This technology has become increasingly popular in vehicles designed for extreme driving conditions, such as off-roaders and high-performance sports cars. At its core, a turbocharger operates on the principle of compressing air entering the engine, allowing for more efficient burning of fuel and increased power output.

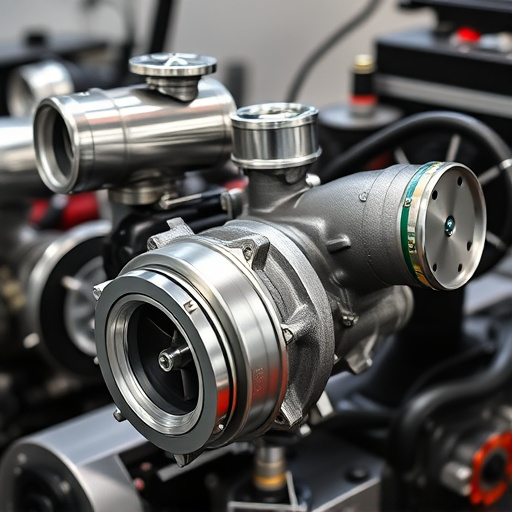

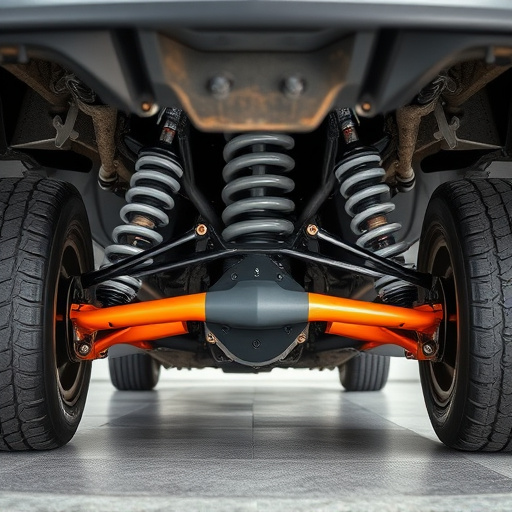

The key components of a turbocharger system include the turbine, compressor, and intercooler. The turbine is driven by exhaust gases exiting the engine, which in turn spins the compressor to force more air into the combustion chamber. This process increases the charge density of the air entering the engine, resulting in enhanced performance. High-quality performance air filters play a crucial role in ensuring clean and optimal airflow to the turbocharger, while carefully designed intake components and brake components contribute to maintaining stability and control during extreme driving conditions.

Challenges in Extreme Driving Conditions: Heat, Pressure, and Durability

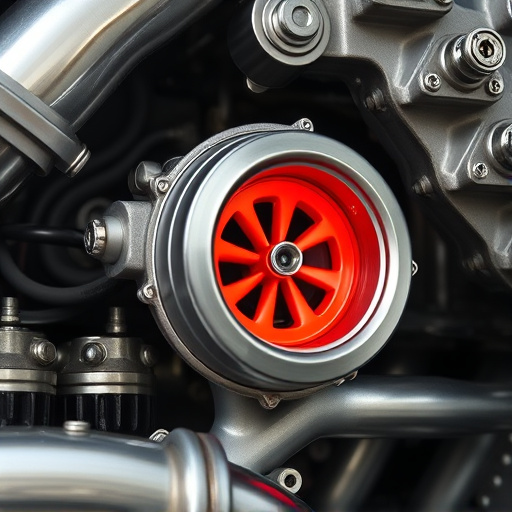

Driving conditions that are extreme present unique challenges for any vehicle component, and a turbocharger system is no exception. Heat is a significant factor; high-performance turbos can reach and even exceed temperatures of up to 500°F (260°C), demanding robust materials and cooling mechanisms. In such environments, the turbocharger’s bearing housing, wheels, and other parts must withstand intense heat without compromising integrity.

Moreover, extreme pressure is another obstacle. Turbochargers are designed to compress air, generating immense pressure that can exceed 30 psi (pounds per square inch). In harsh conditions, this pressure increases, putting a strain on seals, gaskets, and other components. Durability becomes paramount; regular exposure to high heat, pressure, and varying atmospheric conditions can lead to premature wear and failure of turbocharger parts, necessitating the use of high-quality materials and robust construction, often aided by specialized coatings and sealing mechanisms. Additionally, proper maintenance, including regular air filter kits replacements and muffler tips inspections, is crucial to ensure optimal performance and longevity in extreme driving situations.

Engineering Solutions: Enhancing Turbocharger Performance in Harsh Environments

In extreme driving conditions, whether it’s rugged off-road trails or intense racing tracks, a turbocharger system faces unique challenges. Traditional turbochargers may struggle with variations in air density, extreme temperatures, and dusty or muddy air intake systems. To overcome these hurdles, engineers have developed innovative solutions that enhance turbocharger performance under harsh environments.

These advancements focus on key areas like improving air intake efficiency by designing more robust air filters and optimized air intake systems, ensuring a steady supply of cool, dense air even in challenging conditions. Additionally, specialized materials and cooling mechanisms are incorporated into the turbocharger design to withstand high temperatures and maintain optimal performance. Furthermore, durable and lightweight components, including upgraded brake rotors for better heat dissipation, contribute to enhanced overall system reliability during intense driving scenarios.

In extreme driving conditions, a robust turbocharger system is essential for maintaining performance and reliability. By understanding the principles and components of these systems, engineers can develop innovative solutions to overcome challenges related to heat, pressure, and durability. This article has explored these complexities and highlighted engineering advancements that enhance turbocharger performance in harsh environments, ensuring optimal vehicle functionality under any circumstance.