Charge pipes, integral in vehicle systems for fluid management under extreme conditions, especially in high-performance brakes and suspensions, require strategic material selection by engineers to ensure heat resistance and durability. Using advanced materials science, these pipes incorporate alloys like stainless steel or composites with exceptional thermal properties for enhanced heat conductivity, preventing premature wear and ensuring structural integrity. Modern manufacturing processes and rigorous quality control measures further guarantee their reliability in intense automotive environments.

Charge pipes, integral components in various industries, face significant challenges when exposed to high temperatures. This article explores the science behind these resilient structures, delving into material choices and design strategies that enable them to withstand extreme conditions. We dissect the intricate balance between performance and durability, shedding light on manufacturing techniques ensuring charge pipes’ longevity. By understanding these elements, we can optimize their usage, enhancing overall system efficiency and safety in demanding environments.

- Understanding Charge Pipes and Their Challenges

- Material Science Behind High-Temperature Resistance

- Design and Manufacturing Techniques for Durability

Understanding Charge Pipes and Their Challenges

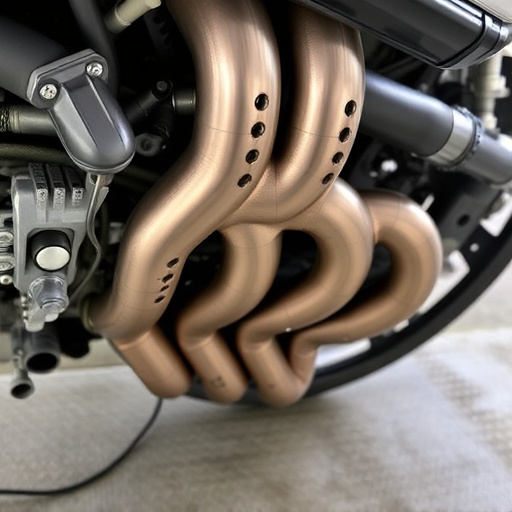

Charge pipes, integral parts of vehicle systems, play a crucial role in managing and conveying fluids, particularly under extreme conditions. These pipes are designed to handle high-pressure and high-temperature environments, often found in performance brakes and suspension kits. However, they face unique challenges due to their exposure to intense heat, especially during frenetic driving sessions or when integrated into racing cars.

The primary obstacle is maintaining structural integrity while withstanding repeated thermal stresses. High temperatures can cause metal fatigue, leading to potential failures if not adequately addressed. Therefore, engineers must carefully select materials that offer excellent heat resistance and durability, ensuring the charge pipes can endure the rigors of intense use without compromising safety or performance.

Material Science Behind High-Temperature Resistance

The material science behind charge pipes’ high-temperature resistance is a fascinating aspect that sets them apart from ordinary automotive components. These pipes are engineered to withstand extreme conditions, often found in performance cars and racing applications. The key lies in selecting materials with exceptional thermal properties, such as advanced alloys and specialized composites. These materials offer superior heat conductivity, ensuring the charge pipes remain cool even under heavy load and high-speed operations.

Unlike traditional exhaust mufflers or suspension components that may falter in extreme temperatures, charge pipes are designed to manage heat efficiently. This is crucial for maintaining optimal performance and longevity. The materials’ ability to resist thermal expansion and contraction prevents premature wear and ensures the pipes remain structurally intact. This feature is especially beneficial when paired with high-performance brakes, as it contributes to overall vehicle stability during intense driving conditions.

Design and Manufacturing Techniques for Durability

The design and manufacturing techniques employed for charge pipes are pivotal to their ability to withstand high temperatures, ensuring optimal performance in demanding automotive environments. Engineers focus on materials science, utilizing high-temperature resistant alloys like stainless steel or specialized composites. These advanced materials not only endure extreme heat but also resist corrosion, a common issue in high-performance vehicles.

Manufacturing processes involve precision engineering and state-of-the-art technologies to create seamless charge pipes with minimal flaws. Techniques such as laser welding and advanced casting methods ensure structural integrity, enabling the pipes to withstand the pressure and temperature changes associated with performance air filters and intake components. Additionally, implementing robust quality control measures during production guarantees consistency and reliability, vital for maintaining optimal vehicle suspension components and overall system efficiency.

Charge pipes, pivotal in modern vehicle systems, demand exceptional high-temperature resistance. By leveraging advanced material science, engineers now employ innovative design and manufacturing techniques to create durable charge pipes capable of withstanding extreme conditions. These advancements ensure reliable performance, safety, and efficiency in today’s demanding automotive landscape.