Direct-to-Film Transfers (DTF) transform custom printing, offering a modern, efficient process that skips traditional steps. By transferring designs from digital files to film, then applying them with heat and pressure, DTF ensures quick turnaround times and versatile applications on materials like posters, banners, and textiles. Outperforming screen printing and DTG methods in quality and cost-effectiveness, DTF is ideal for small businesses and entrepreneurs creating vibrant, long-lasting custom products.

In the evolving landscape of visual media, Direct-To-Film (DTF) transfers have emerged as a modern alternative to traditional print methods. This cutting-edge technology promises enhanced quality, cost-effectiveness, and accessibility. However, understanding the nuances between DTF transfers and conventional printing techniques is paramount for informed decision-making. This article delves into these contrasting approaches, comparing their respective quality outputs, financial implications, and availability.

- Understanding Direct-To-Film Transfers: A Modern Approach

- Traditional Print Methods: The Established Techniques

- Comparing Quality, Cost, and Accessibility

Understanding Direct-To-Film Transfers: A Modern Approach

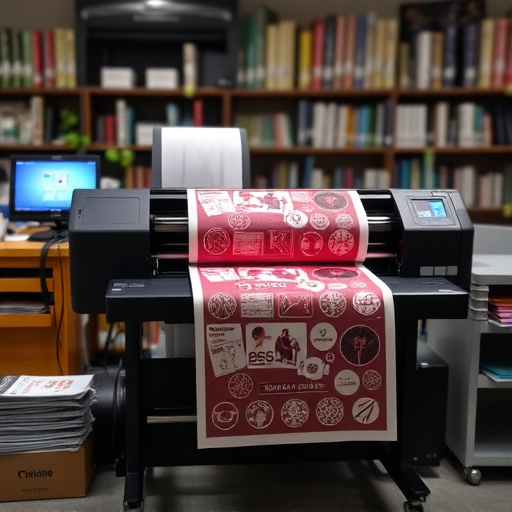

Direct-To-Film Transfers (DTF) represent a modern approach to printing on various materials, including custom t-shirts and other textiles. This innovative method eliminates traditional steps involved in print production, offering a streamlined process that is both efficient and cost-effective. With DTF, designs are directly transferred from digital files onto film, which is then used to apply the artwork to the desired substrate using heat and pressure.

This cutting-edge technology has gained significant traction, especially among small businesses and entrepreneurs looking to create custom products swiftly. Unlike traditional print methods that may require specialized equipment and a longer setup time, DTF printing for light fabrics allows for quick turnaround times. Its versatility is evident in its ability to produce high-quality results on various materials, making it suitable not just for t-shirts but also for items like posters, banners, and even stickers.

Traditional Print Methods: The Established Techniques

Traditional Print Methods have been the go-to approach for many years, offering a range of techniques that have become established in the industry. This often involves using printing presses to apply ink directly onto fabric or other materials. For hoodies and various garments, screen printing is a popular method where a fine mesh screen is used to transfer ink, allowing for detailed designs and vibrant colors. Each color in an image requires its own screen, making it a time-consuming process but yielding high-quality results that are durable and suitable for mass production.

Another traditional technique is heat pressing or DTG (Direct to Garment) printing, where designs are first printed onto special paper using inkjet printers. These papers are then pressed onto the fabric under high heat and pressure, fusing the design permanently. This method, while more versatile than screen printing, allows for personalization on demand, making it ideal for creating direct to film personalized hoodies or dtf transfers. It offers a wide range of color options and is suitable for various fabric types.

Comparing Quality, Cost, and Accessibility

When comparing Direct-to-Film (DTF) transfers with traditional print methods, one key area to consider is quality. DTF offers a superior level of detail and color accuracy when printing on various materials, including t-shirts and other textiles. This method directly bonds ink to the substrate, resulting in vibrant, long-lasting colors that resist fading. Traditional print methods, such as screen printing or heat transfers, can sometimes exhibit lower resolution or limited color range, especially when dealing with fine details or intricate designs.

In terms of cost, DTF for t-shirts and other items is often a more economical option in the long run. While the initial investment in dtf heat transfer paper may be higher than traditional printing supplies, the process eliminates the need for complex setup and equipment like screens or presses. This makes it accessible to small businesses and even individuals looking to create custom designs. Additionally, DTF transfers can print directly onto a wide range of materials without requiring specialized equipment, further reducing costs associated with specific substrates.

Direct-to-film transfers have emerged as a modern alternative to traditional print methods, offering enhanced quality, cost-effectiveness, and improved accessibility. As technology continues to evolve, these innovative techniques are likely to play an increasingly significant role in the film industry. However, understanding the unique advantages and limitations of each method is essential for making informed decisions. By comparing direct-to-film transfers with traditional print processes, filmmakers and enthusiasts alike can navigate the ever-changing landscape of film preservation and production.