Exhaust cutout valves are essential for optimizing vehicle performance by managing exhaust gas flow. Installation requires initial tuning and testing to ensure seamless operation. Advanced tuning techniques allow precise control over engine behavior, enhancing power output and throttle response while minimizing backpressure. Complementing with air filters and cat-back exhaust systems further improves performance and driving experience.

After installing exhaust cutout valves, proper tuning is crucial for optimal engine performance. This article guides you through the essential steps, from understanding these innovative components that allow precise control over exhaust gas flow, to post-installation tuning and advanced techniques. Learn how to fine-tune your system, ensuring smooth operation, enhanced power delivery, and improved throttle response—all by leveraging the unique capabilities of exhaust cutout valves.

- Understanding Exhaust Cutout Valves and Their Function

- Post-Installation: Initial Tuning and Testing Procedures

- Optimizing Performance: Advanced Tuning Techniques

Understanding Exhaust Cutout Valves and Their Function

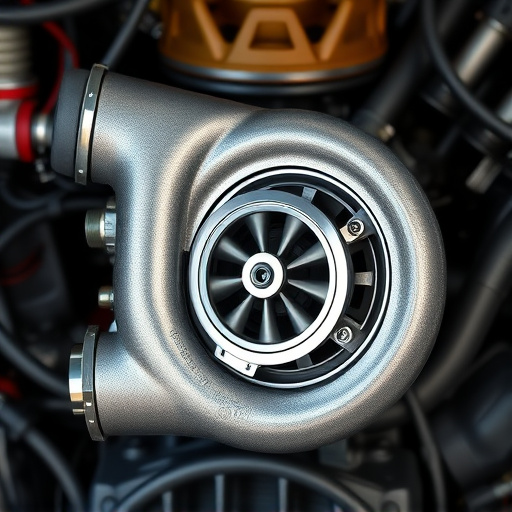

Exhaust cutout valves are an essential component in a vehicle’s exhaust system, designed to redirect or restrict airflow for optimal performance. These valves operate based on engine speed and temperature, allowing for precise control over exhaust gas flow. By adjusting the valve’s position, they can enhance engine power, improve throttle response, and even reduce noise levels. This makes them a popular choice among car enthusiasts looking to fine-tune their vehicles’ performance.

Understanding how exhaust cutout valves function is crucial when making tuning adjustments. They work in conjunction with other components like brake rotors, air filter kits, and cold air intakes to regulate engine output. After installing or modifying these valves, it’s vital to reassess the vehicle’s settings, ensuring that the engine management system recognizes and compensates for the changed dynamics. This ensures smooth operation and maximizes the benefits of the exhaust cutout valve setup.

Post-Installation: Initial Tuning and Testing Procedures

After installing exhaust cutout valves, it’s crucial to conduct initial tuning and testing procedures for optimal performance. The first step involves checking the system for any leaks by starting the engine and inspecting all connections. This is essential as even a small leak can significantly impact engine efficiency. Once the system is sealed, focus on adjusting the air-fuel ratio using a dyno or diagnostic tools to ensure the engine runs smoothly and efficiently with the new setup.

Next, test the exhaust cutout valves’ functionality by simulating various driving conditions. This includes accelerating at different speeds, idling, and climbing hills to see how the valves respond. Additionally, check the vehicle’s braking performance since exhaust cutout valves can affect airflow around brake rotors, potentially altering their cooling efficiency. Ensure the brakes are working as expected, especially under high-performance scenarios where heat buildup could be a concern.

Optimizing Performance: Advanced Tuning Techniques

After installing exhaust cutout valves, advanced tuning techniques can further optimize your vehicle’s performance. These methods allow for precise control over engine behavior, particularly during low-to-mid RPM ranges where exhaust cutouts are most effective. One key strategy involves adjusting the timing of valve opening and closing to minimize backpressure in the exhaust system. This not only enhances engine responsiveness but also improves throttle sensitivity, resulting in a more dynamic driving experience.

Additionally, integrating performance air filters and cat-back exhaust systems can complement the tuned setup. High-flow air filters provide cleaner, cooler air to the engine, boosting its power output. Meanwhile, a cat-back exhaust system reduces backpressure further, allowing for smoother gas flow and improved torque delivery. Combining these components ensures your vehicle not only sounds aggressive but also performs at its peak, especially with the strategic placement of exhaust cutout valves.

After installing exhaust cutout valves, proper tuning is essential for optimal vehicle performance. Beginning with initial setup and testing, as outlined in this article, allows for a solid foundation. As you explore advanced tuning techniques, you can fine-tune your system to achieve the best results. Remember, understanding how exhaust cutout valves function is key to unlocking your vehicle’s full potential, providing both enhanced performance and control.