Intercooler piping is vital for high-performance vehicles, managing heat absorption and delivery between engine and intake components to maintain consistent cold air intake temperatures. This process optimizes combustion efficiency, boosts power output, reduces wear on brakes, and enhances overall automotive design. Efficient design requires strategic planning with insulation, precise installation, and performance brakes for reliability in extreme conditions.

Intercooler piping is a vital component in automotive cooling systems, playing a crucial role in maintaining optimal engine performance. This article explores the essential concept of intercooler piping, focusing on how it helps regulate consistent intake temperatures. We’ll delve into the fundamentals, highlighting its advantages and guiding you through installation considerations for efficient engine management. By understanding intercooler piping, car enthusiasts can enhance their vehicle’s capabilities.

- Understanding Intercooler Piping Basics

- Benefits of Consistent Intake Temperatures

- Design and Installation Considerations

Understanding Intercooler Piping Basics

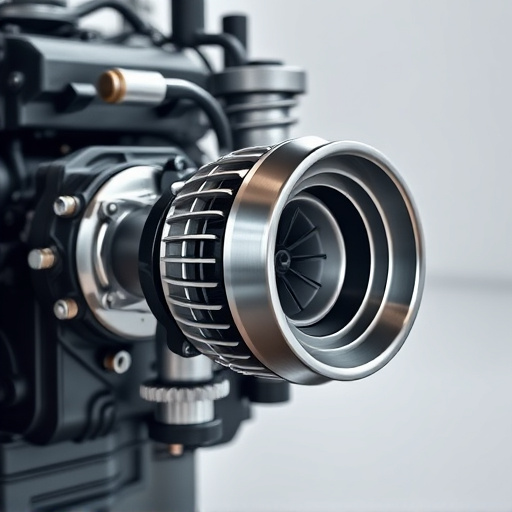

Intercooler piping is a vital component in many high-performance vehicles and power sports equipment. It’s designed to manage and direct cooling fluids, typically between the engine and intake components, ensuring optimal operating temperatures. At its core, intercooler piping consists of a series of tubes or channels that facilitate the flow of liquid coolants, absorbing heat from the engine and delivering it to an intercooler for dissipation. This process plays a crucial role in maintaining consistent intake air temperatures, which can significantly enhance engine performance and efficiency.

Understanding intercooler piping basics involves grasping how it interacts with other brake components and intake components. Cold air intakes, for instance, rely on efficient piping to draw in cool, dense air, enhancing combustion and power output. By managing heat transfer, intercooler piping contributes to the overall health and effectiveness of these systems, ensuring that both engine and intake components operate within their designed temperature ranges.

Benefits of Consistent Intake Temperatures

Maintaining consistent intake temperatures is paramount for optimal engine performance. Intercooler piping plays a pivotal role in achieving this by regulating the air entering the engine. This ensures that the air is at the ideal temperature, enhancing combustion efficiency and boosting power output. When air intake systems are kept cool, the engine can breathe better, leading to smoother transitions between acceleration and deceleration, thereby improving overall vehicle performance.

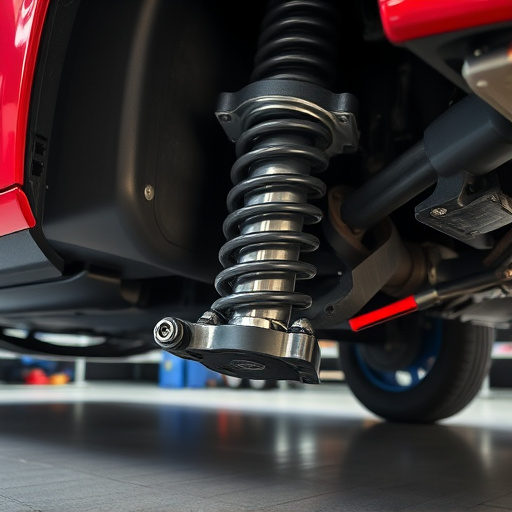

Moreover, consistent temperatures help prevent premature wear on critical components like brake pads, which are often affected by heat-induced expansion. By keeping the air intake system at a stable temperature, intercooler piping contributes to longer lasting performance brakes, reducing maintenance costs over time. This synergy between efficient air intake and sustained brake performance underscores the importance of intercooler piping in modern automotive design.

Design and Installation Considerations

When designing an intercooler piping system, it’s crucial to consider several factors that will impact its performance and efficiency. The primary goal is to ensure a steady flow of cold air to the turbocharger, which requires strategic routing and sizing of pipes. Proper insulation is essential to maintain the desired temperature drop across the intercooler core, minimizing heat pickup from surrounding components like hot exhaust gases or intense engine bay temperatures.

Installation of intercooler piping demands precision and attention to detail. It’s vital to secure pipes firmly, using compatible brackets or hangers, to prevent vibration-induced damage or leaks. Additionally, ensuring adequate clearance for air flow and proper alignment with the intercooler and cold air intake (CAI) is fundamental. Upgrading to performance brakes, like those designed for high-performance vehicles, can further enhance system reliability by managing heat dissipation more effectively during intense driving conditions.

Intercooler piping is an essential component in maintaining optimal engine performance. By consistently managing intake temperatures, these systems enhance engine efficiency, reduce turbulence, and improve overall power output. When designing and installing intercooler piping, consider factors like material choices, routing optimization, and efficient heat dissipation to ensure peak engine performance and longevity. Invest in high-quality piping for a reliable cooling system that will keep your engine running cool under pressure.