DTF Hot Peel Film revolutionizes custom apparel printing with direct application of designs, offering vibrant results and easy removal post-printing. Ideal for graphic tees, hoodies, and complex transfers, this technology provides a cost-effective, high-quality solution for on-demand printing, benefiting businesses in advertising, packaging, and fine art. Key advantages include precise color reproduction, sharp details, and durable prints, eliminating common issues like ink bleeding or smudging. Optimal results require proper workspace preparation, high-quality film, meticulous substrate cleaning, accurate film application using a heat press, and thorough inspection.

Discover how DTF Hot Peel Film is transforming the printing industry. This innovative technology offers unparalleled precision and quality, ensuring crisp, vibrant prints every time. From enhancing color accuracy to simplifying the peeling process, DTF Hot Peel Film is a game-changer for professional printers. Learn about its benefits, implementation tips, and best practices in this comprehensive guide, designed to help you unlock superior print quality using DTF Hot Peel Film.

- Understanding DTF Hot Peel Film Technology

- Benefits of Using DTF Hot Peel Film for Print Quality

- Implementing DTF Hot Peel Film: Tips and Best Practices

Understanding DTF Hot Peel Film Technology

DTF Hot Peel Film technology has revolutionized the printing industry, especially in the realm of custom apparel. This innovative process allows for direct application of designs onto various surfaces, including fabric, without the need for traditional screen printing methods. By using a special film that adheres to the material, printers can achieve precise, vibrant results with a range of colors and intricate details. The ‘hot peel’ aspect refers to the heating process that facilitates easy removal of the film after printing, leaving behind only the ink transferred to the fabric.

This technology is particularly beneficial for creating custom graphic tees, direct-to-film personalized hoodies, and even complex custom dtf transfers. It offers a cost-effective solution for businesses and individuals looking to produce high-quality, unique designs with speed and efficiency. With its ability to mimic screen printing’s vibrancy and detail, DTF Hot Peel Film is a game-changer in the world of on-demand printing, ensuring that personalized items can be created and delivered promptly while maintaining exceptional print quality.

Benefits of Using DTF Hot Peel Film for Print Quality

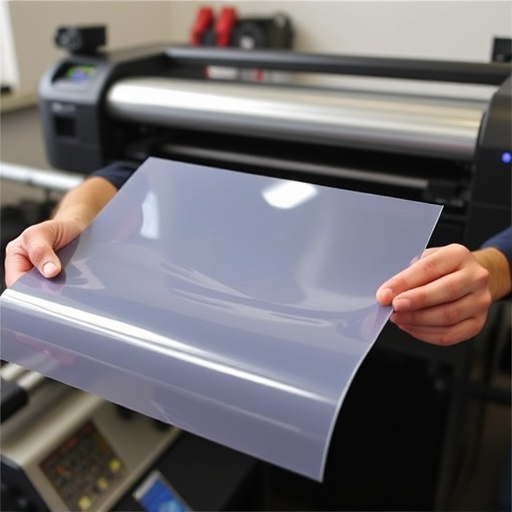

Using DTF Hot Peel Film offers significant advantages for enhancing print quality, especially when employing a direct to film printer. The film’s unique properties ensure precise color reproduction and sharp details, resulting in high-resolution prints that rival traditional printing methods. This is particularly beneficial for businesses and professionals who require consistent and exceptional output, whether it’s for advertising, packaging, or fine art printing.

Furthermore, the DTF printer‘s ability to directly apply ink onto the film allows for a more precise and controlled printing process. The best DTF printer configurations can produce vibrant, durable prints with excellent color consistency. This method eliminates potential issues like ink bleeding or smudging commonly found in other printing techniques, ensuring that final outputs maintain their integrity and visual appeal.

Implementing DTF Hot Peel Film: Tips and Best Practices

Implementing DTF Hot Peel Film requires careful consideration and best practices to achieve optimal print quality on custom graphic tees or DTG (Direct-to-Garment) transfers. Firstly, ensure your work area is clean and well-ventilated due to the heat involved in the process. Use a high-quality DTF film suitable for your printing needs; cheap alternatives may compromise resolution and adhesion.

Before applying the film, properly prepare your substrate—usually a blank t-shirt—by cleaning it with isopropyl alcohol to remove any oils or dirt. Position the DTF film accurately over the design area, making sure no air bubbles are trapped beneath. Heat the film using a professional heat press at the recommended temperature and time for your specific material. Once peeled off, inspect the print for any issues like smudges or misalignments, and make adjustments as necessary. This meticulous approach guarantees superior results in creating custom t shirts with vibrant, long-lasting designs.

The adoption of DTF Hot Peel Film technology offers a game-changing approach to enhancing print quality, revolutionizing the way we produce visually stunning results. By understanding its unique benefits and implementing best practices, printers can achieve exceptional detail, vibrant colors, and crisp outlines, elevating their work to new heights. This innovative film is a testament to the ongoing evolution of printing technology, ensuring folks in the industry stay ahead of the curve.