Straight pipe exhaust setups' pipe diameter impacts sound and power output, with smaller diameters restricting airflow and larger ones facilitating freer flow. Balancing performance gains with weight, cost, and noise levels is key. Larger pipes enhance airflow, boosting horsepower and torque, but choices should consider backpressure, gas flow dynamics, heat transfer efficiency, and emissions standards. Optimizing exhaust flow unlocks engine potential, impacting power output and torque delivery. Strategic geometry and high-flow air filters further enhance performance.

Choosing the right pipe diameter for your performance exhaust is a crucial step in enhancing engine performance. This article guides you through understanding how pipe diameter impacts exhaust flow and overall engine efficiency. We’ll explore key factors to consider, such as engine type and output requirements, to ensure optimal performance. Learn how optimizing exhaust flow can lead to better throttle response and horsepower gains, making your straight pipe exhaust a true game-changer on the road.

- Understanding Pipe Diameter Impact on Exhaust Performance

- Factors to Consider When Choosing Pipe Diameter

- Optimizing Exhaust Flow for Enhanced Engine Performance

Understanding Pipe Diameter Impact on Exhaust Performance

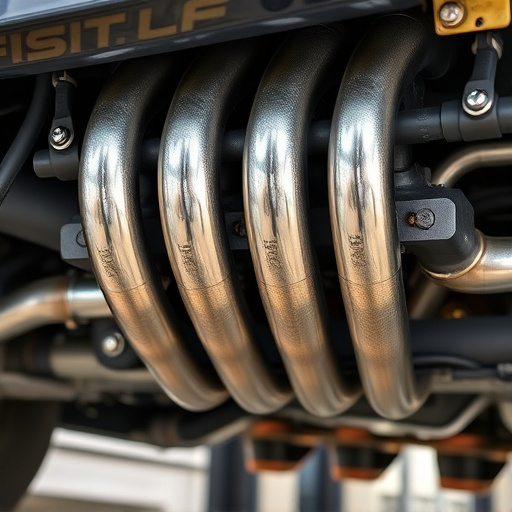

The pipe diameter plays a significant role in shaping the overall performance of an exhaust system, especially in straight pipe exhaust setups. As air flows through the pipes, its velocity and pressure drop across different diameters can dramatically affect the sound and power output. Smaller diameters restrict airflow, causing higher backpressure, which can reduce engine power. Conversely, larger diameters allow for freer flow, enhancing exhaust gas expulsion and potentially improving vehicle performance.

When considering pipe diameter, it’s crucial to balance the desire for improved performance with practical factors like weight, cost, and noise levels. Exhaust tips designed for specific pipe sizes contribute to tailored performance gains while ensuring a harmonious blend of power and sound. Additionally, pairing your exhaust system with high-quality performance air filters can further optimize vehicle performance by enhancing engine intake efficiency.

Factors to Consider When Choosing Pipe Diameter

When selecting a pipe diameter for a performance exhaust system, several key factors come into play. One primary consideration is the overall goal and desired outcome of the modification. Different pipe diameters can significantly impact the exhaust note, power delivery, and flow efficiency of your vehicle’s engine. For instance, larger pipes can accommodate higher airflow rates, resulting in increased horsepower and torque, especially at high RPMs. This makes them a popular choice for those seeking improved straight-pipe exhaust performance.

Additionally, the type of vehicle, engine configuration, and existing exhaust system play crucial roles. High-performance parts and suspension components often require specific pipe diameters to ensure optimal compatibility and functionality. Factors such as backpressure, gas flow dynamics, and the efficiency of heat transfer should also be evaluated. For example, a cat-back exhaust system might dictate certain diameter choices to maintain balance between performance gains and legal emissions standards.

Optimizing Exhaust Flow for Enhanced Engine Performance

Optimizing exhaust flow is key to unlocking an engine’s full potential. In a straight pipe exhaust system, gases flow freely, allowing for rapid expulsion and improved turbospire velocity. This promotes efficient combustion and enhances overall engine performance. By ensuring smooth and unobstructed airflow, the right pipe diameter can make a significant difference in power output and torque delivery.

When considering a performance exhaust system, the goal is to strike a balance between flow restrictions and backpressure. Well-designed exhaust systems with strategic geometry and strategically placed components can optimize gas exchange, leading to increased horsepower and improved throttle response. Integrating high-flow performance air filters further enhances this process by ensuring a consistent and rich supply of cool, dense air into the engine, complimenting the optimized exhaust flow.

When selecting a pipe diameter for your performance exhaust system, understanding the interplay between flow dynamics and engine performance is key. By considering factors like engine specifications, desired exhaust notes, and legal restrictions, you can optimize your exhaust for enhanced power and efficiency. Remember, a well-chosen straight pipe exhaust not only improves sound but also enhances overall engine performance, making it a crucial component in any modification journey.