Blow off valves, crucial for regulating pressure release in turbocharged/supercharged engines, face issues like clogged venturi (restricting airflow) or faulty closure. Regular maintenance, including visual inspections, pressure tests, and cleaning/replacement of filters and vents, is essential to prevent damage and maintain optimal engine performance. Proactive measures like regular inspections, upgrades, and clean air filters extend valve life.

“Unleash your vehicle’s performance potential by delving into the essential component that is the blow off valve. This crucial mechanism, designed to release compressed air from the engine, can often fall victim to various issues, leading to reduced efficiency and even damage.

In this comprehensive guide, we’ll explore the most common problems with blow off valves, equip you with diagnostic tools for identifying malfunctions, and provide effective fixes along with maintenance strategies to keep these valves in top shape.”

- Understanding Common Blow Off Valve Issues

- Diagnosing and Testing for Malfunctions

- Effective Fixes and Maintenance Strategies

Understanding Common Blow Off Valve Issues

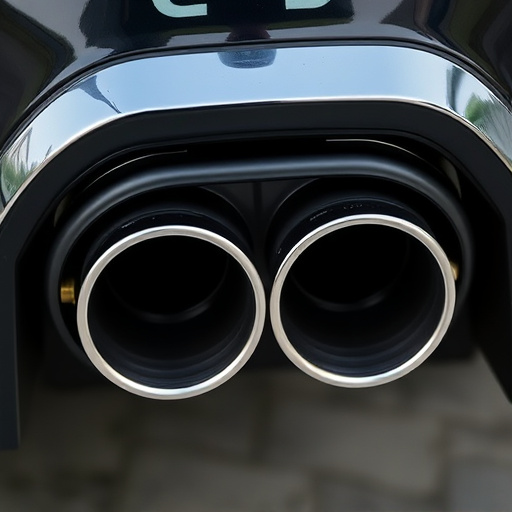

Blow off valves are an essential component in turbocharged or supercharged engines, designed to safely release excess pressure from the combustion chamber when the engine is under high load. However, these valves can encounter several common issues that impact performance and efficiency. One of the most frequent problems is a clogged or contaminated venturi, which restricts airflow and reduces the valve’s effectiveness. This can lead to increased backpressure in the exhaust system, potentially damaging other components like exhaust tips and suspension parts.

Another issue arises when the blow off valve fails to close properly, causing constant pressure release even under normal operating conditions. This situation can be caused by worn or damaged seals, incorrect adjustment, or issues with the actuator mechanism. Left unchecked, it may result in decreased fuel efficiency, increased wear on brake pads, and even engine performance problems. Regular maintenance and prompt attention to any unusual noises or performance indicators are crucial for keeping blow off valves in optimal working condition.

Diagnosing and Testing for Malfunctions

Diagnosing and testing blow off valves for malfunctions is a crucial step in ensuring optimal engine performance. Start by visually inspecting the valve for any signs of damage or corrosion, as these can hinder its operation. Check for proper alignment and secure connections to the manifold and other components. A functional blow off valve should open when engine pressure exceeds a certain threshold, allowing compressed air to escape. One common test involves using a pressure gauge to monitor the intake pressure under load; a sudden drop indicates a potential issue with the valve’s operation.

Additionally, listening for unusual noises coming from the exhaust mufflers or feeling abrupt power loss can signal problems with the blow off valve or related performance exhaust components. If the valve is not opening fully, it might be due to a clogged filter or obstructions in the vent line, affecting engine breathing and potentially leading to poor throttle response and reduced horsepower. In such cases, cleaning or replacing filters and ensuring unobstructed vents can resolve these secondary issues associated with performance brakes and exhaust systems.

Effective Fixes and Maintenance Strategies

Regular maintenance is key to preventing common issues with blow off valves. One effective strategy is to inspect and clean or replace the valve regularly, especially if it’s exposed to harsh conditions or high-performance applications. This includes checking for any debris buildup, corroded components, or leaks, which can disrupt the optimal functioning of the valve.

Additionally, upgrading suspension kits and ensuring proper alignment can mitigate excessive stress on the blow off valve. Keeping brake rotors clean and in good condition also plays a vital role, as dirt and dust accumulation can impact valve performance. Regular air filter kit replacements are another crucial maintenance step, as a dirty air filter can restrict airflow and put unnecessary strain on the valve. These proactive measures will help ensure smooth operation, enhance engine performance, and potentially extend the life of your blow off valve.

Blow off valves are essential components in many automotive systems, ensuring proper engine performance. However, like any part, they can encounter issues, leading to potential problems. By understanding common problems, effectively diagnosing and testing malfunctions, and implementing suitable fixes and maintenance strategies, car owners and mechanics can keep blow off valves in top condition, enhancing overall engine health and efficiency. Regular attention to these critical components will help prevent costly repairs and ensure your vehicle continues to run smoothly.