Polyurethane bushings offer superior compression resistance, flexibility, and durability for automotive and industrial uses. They maintain shape under pressure, prevent deformation in critical components like brake rotors and exhaust systems, minimize noise transmission, and ensure airflow efficiency in intake parts. Ideal for high-performance cars and tuning modifications, these bushings enhance vehicle longevity and performance by reducing wear and vibrations.

Polyurethane bushings, a versatile solution for shock absorption and isolation, offer unparalleled performance in various applications. This article explores their unique properties and advantages, highlighting how they resist compression and deformation. We delve into the critical role of compression resistance in ensuring durability and discuss strategies to prevent deformation, maintaining structural integrity. By understanding these aspects, you’ll appreciate why polyurethane bushings are a preferred choice across industries.

- Understanding Polyurethane Bushings: Properties and Advantages

- Compression Resistance: The Key to Durability

- Deformation Prevention: Ensuring Structural Integrity

Understanding Polyurethane Bushings: Properties and Advantages

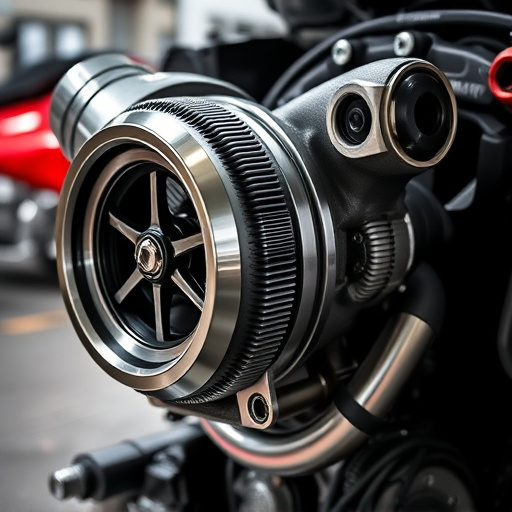

Polyurethane bushings are a type of high-performance rubber material that offers exceptional resistance to compression and deformation. This makes them ideal for a variety of applications, especially in automotive and industrial settings. These bushings are known for their versatility, as they can be molded into various shapes and sizes, catering to the specific needs of different machines and vehicles.

One of the key advantages of polyurethane is its durability. Unlike traditional rubber, which can degrade over time due to exposure to heat or oils, polyurethane retains its strength and flexibility. This makes it a popular choice for intake components in high-performance cars and air filter kits, ensuring they maintain their integrity under extreme conditions. Additionally, polyurethane’s low-friction properties reduce wear and tear, making them an excellent solution for parts that require smooth movement and longevity.

Compression Resistance: The Key to Durability

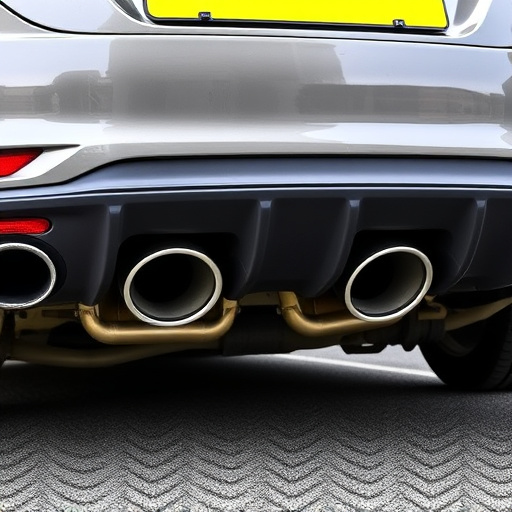

Polyurethane bushings are renowned for their exceptional compression resistance, making them an indispensable component in various automotive applications. This unique property ensures that the bushings maintain their shape and integrity even under extreme pressure and force, a critical aspect for durability. When installed in muffler tips or exhaust systems, these bushings can withstand the constant vibrations and pulsations generated by exhaust mufflers without succumbing to compression or deformation.

This feature is particularly beneficial for intake components as well, where polyurethane bushings act as vital connectors, reducing noise transmission and ensuring a smooth flow of air. Their resistance to compression prevents premature wear and tear, extending the lifespan of both automotive parts and systems like muffler tips and exhaust mufflers.

Deformation Prevention: Ensuring Structural Integrity

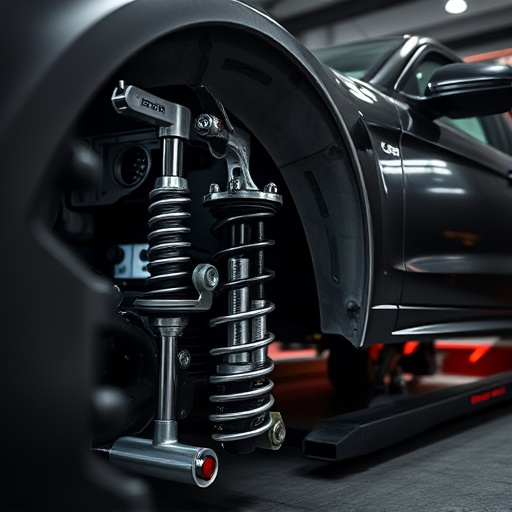

One of the key benefits of polyurethane bushings is their exceptional ability to prevent deformation, ensuring the structural integrity of various automotive components. These highly durable materials are designed to withstand extreme forces and pressures, making them ideal for critical parts like brake rotors, where precise alignment and stability are paramount. By maintaining their shape even under compression, polyurethane bushings contribute to the overall longevity and performance of vehicles’ suspension systems.

Moreover, when integrated into coilover kits or cat-back exhaust systems, these bushings offer enhanced stability and reduced noise vibration. Their resistance to deformation guarantees that components like shock absorbers and exhaust pipes maintain their alignment, preventing premature wear and ensuring smooth, efficient operation. This is particularly crucial for vehicle owners seeking to maximize the performance of their tuning modifications.

Polyurethane bushings, with their exceptional compression resistance and deformation prevention properties, offer a reliable solution for various industrial applications. By understanding the unique advantages of these bushings, such as their high durability and structural integrity, engineers can make informed decisions to enhance overall system performance. Incorporating polyurethane bushings into designs resistant to compression and deformation ensures longevity and minimizes maintenance needs, making them an ideal choice for demanding environments.