Commercial DTF (Direct to Fabric) Printing, using heat-transferred ink, is revolutionizing apparel production with intricate, full-color designs on various fabrics, offering cost efficiency and speed compared to traditional printing methods. Ideal for t-shirts and light fabrics, this technology streamlines processes, enhances quality, and caters to diverse sectors, from fashion to home decor. Choosing the right DTF printer involves considering production needs, budget, and compatibility with software, spare parts, and support.

Discover the transformative power of Commercial DTF Printing, a game-changing technology revolutionizing the print industry. This cutting-edge method offers unparalleled efficiency and versatility in today’s fast-paced market. In this comprehensive guide, we demystify Commercial DTF Printing, exploring its benefits and diverse applications. From enhancing productivity to expanding creative possibilities, learn how the right equipment can unlock new levels of efficiency for your business.

- Understanding Commercial DTF Printing: The Basics Unveiled

- Benefits and Applications: Revolutionizing Print Industry

- Choosing the Right Equipment: A Comprehensive Guide

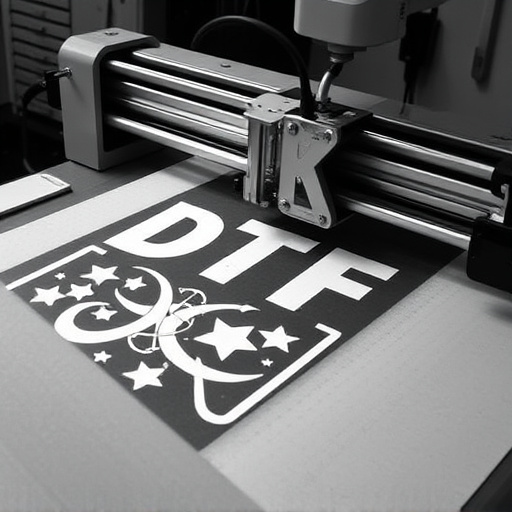

Understanding Commercial DTF Printing: The Basics Unveiled

Commercial DTF (Direct to Fabric) Printing is a cutting-edge technology revolutionizing the apparel industry. It’s a process that allows designers and manufacturers to create intricate, full-color designs directly onto various fabrics with remarkable precision and speed. This method eliminates the need for costly and time-consuming screen printing or embroidery, making it an attractive option for businesses seeking efficient and cost-effective solutions.

At its core, DTF Printing involves a specialized printer that uses heat to transfer ink onto fabric. Unlike traditional printing methods, it’s versatile enough to work on a wide range of materials, from heavy cotton tees to lightweight silks. For those interested in applying designs to t-shirts and light fabrics, DTF Printing offers an efficient alternative to traditional techniques, ensuring high-quality results while streamlining production processes. The heat press plays a crucial role, acting as the tool that fuses the ink onto the fabric, resulting in vibrant and durable prints.

Benefits and Applications: Revolutionizing Print Industry

Commercial DTF (Direct to Fabric) Printing is transforming the print industry with its remarkable efficiency and versatility. This cutting-edge technology offers a game-changing approach to fabric printing, eliminating traditional barriers and opening up endless creative possibilities. By directly applying designs onto various fabrics, DTF printers enable rapid production times and high-quality outcomes, making it an attractive option for businesses across industries.

The applications of Commercial DTF Printing are vast, from clothing and accessory design to promotional merchandise and even decorative home furnishings. Its ability to handle a wide range of fabric types and colors allows for exceptional customization, catering to unique brand identities and individual preferences. With advanced printing techniques and precise color reproduction, DTF printers ensure that designs are vibrant, detailed, and durable, marking a significant advancement in the way we approach fabric-based products.

Choosing the Right Equipment: A Comprehensive Guide

When it comes to choosing the right equipment for Commercial DTF Printing, especially for applications like DTF printing for t-shirts and DTF for Apparel, several factors come into play. The first step is to assess your production needs and budget. Different dtf printers cater to various levels of output and complexity, from entry-level models suitable for small businesses to industrial-grade machines capable of handling high-volume orders. It’s crucial to select a printer that aligns with your expected print volume, design complexity, and material compatibility.

Next, consider the versatility and capabilities of the printer. For instance, look for features like multi-color printing, variable data printing, and direct-to-garment (DTG) capabilities if you plan to offer diverse designs and customization options. Additionally, ensure that the chosen dtf printing equipment is compatible with popular software and has readily available spare parts and technical support to minimize downtime and maximize efficiency in your DTF for Apparel operations.

Commercial DTF (Direct-to-Fashion) printing is transforming the textile industry by offering efficient, versatile, and cost-effective solutions. By understanding its fundamentals, leveraging its benefits, and selecting the appropriate equipment, businesses can unlock new levels of productivity and creativity. This cutting-edge technology promises to redefine print industry standards, making it an exciting time for innovators and entrepreneurs alike.