Hydraulic suspension systems, powered by cylinders, pumps, and switches, offer superior control and performance. Cylinders convert pressure to linear motion for height adjustments, pumps maintain fluid pressure, and switches manage flow, providing customizable comfort, enhanced handling, and improved vehicle performance, especially when integrated with exhaust systems and advanced brakes.

Hydraulic suspension systems have revolutionized ride quality in various vehicles. In this article, we’ll delve into the intricate world of these advanced mechanisms, focusing on key components like cylinders, pumps, and switches. Understanding how these elements work in harmony is essential for appreciating the superior performance and comfort that hydraulic suspension offers. Let’s explore their vital roles in enhancing driving dynamics.

- Understanding Hydraulic Suspension Systems

- Key Components: Cylinders, Pumps, and Switches

- How These Parts Work Together to Enhance Ride Quality

Understanding Hydraulic Suspension Systems

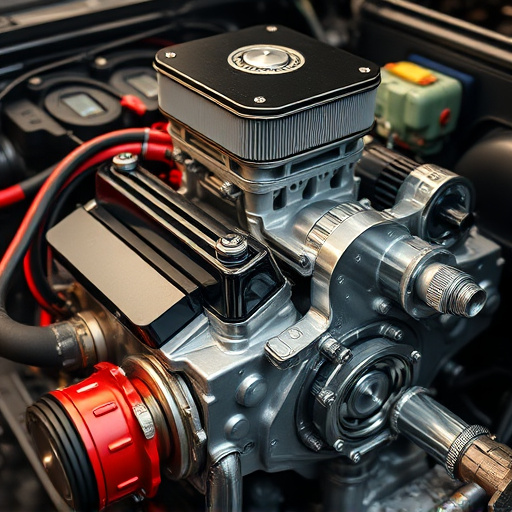

Hydraulic suspension systems are a complex yet effective mechanism designed to enhance vehicle performance and control. These systems utilise a network of cylinders, pumps, and switches to create a smooth and responsive ride. At its core, a hydraulic suspension operates by transferring force from the vehicle’s wheels to the chassis via liquid, allowing for precise adjustment of height, camber, and spring rate.

Understanding how these suspension components interact is crucial. Cylinders act as actuators, converting hydraulic fluid pressure into linear motion, which then adjusts the vehicle’s stance. Pumps generate and maintain this hydraulic pressure, while switches control the flow of fluid to specific cylinders, enabling precise tuning for various driving conditions. This sophisticated setup offers advantages over traditional springs, especially in terms of comfort, handling, and customisability, making it a popular choice for both off-road vehicles and high-performance cars, including those with tailored exhaust systems and advanced performance brakes.

Key Components: Cylinders, Pumps, and Switches

The heart of any hydraulic suspension system lies in its key components—cylinders, pumps, and switches. These elements work in perfect harmony to deliver precise control and smooth operation. Cylinders, made from robust materials, are responsible for converting hydraulic fluid pressure into linear motion, thereby enabling the up-and-down movement of the vehicle’s suspension.

Pumps play a crucial role in the system by generating and maintaining the flow of hydraulic fluid, ensuring consistent pressure throughout. They work in tandem with switches, which act as control mechanisms, allowing drivers to adjust the suspension’s firmness or softness based on road conditions and personal preference. These components, when integrated into a suspension kit, offer not just improved handling and comfort but also enhance vehicle performance, especially when paired with high-quality exhaust tips and performance air filters.

How These Parts Work Together to Enhance Ride Quality

The heart of any hydraulic suspension system lies in its intricate interplay of components: cylinders, pumps, and switches. These parts work in perfect harmony to deliver a smooth and controlled ride. Cylinders, strategically positioned, respond to pump signals to extend or retract, thereby adjusting the vehicle’s height and managing shock absorption. The pump, a critical component, generates hydraulic pressure, ensuring efficient power transfer between the motor and the suspension. This enables rapid responses to road conditions, whether it’s smoothing out bumps or maintaining stable handling.

Switches play a pivotal role in this system by regulating the flow of hydraulic fluid, allowing for precise control over ride height and damping. Together, these elements create a dynamic network that enhances vehicle stability, reduces body roll, and improves overall ride quality. This sophisticated setup is particularly beneficial for off-road adventures or those seeking enhanced performance, as it allows for customizable settings tailored to different driving conditions, even transforming the vehicle’s handling characteristics by integrating with other components like exhaust systems and suspension kits.

Hydraulic suspension systems, with their key components like cylinders, pumps, and switches, offer a sophisticated way to enhance vehicle ride quality. By working in harmony, these parts provide smoother, more controlled movements, ensuring passengers enjoy a comfortable journey. Understanding the intricacies of hydraulic suspension allows automotive enthusiasts and engineers to appreciate its role as a game-changer in vehicle design, making every drive more enjoyable.