Power Stop brakes enhance braking performance with advanced engineering, specialized materials, and efficient heat dissipation. However, they can face issues like reduced efficiency, strange noises, contaminated brake fluid, and worn pads, exacerbated by aggressive driving and varying temperatures. Regular maintenance, including checks and replacements, is vital for optimal performance and lifespan, even with performance exhaust systems. Troubleshooting requires a systematic approach, starting with visual inspections, checking for leaks and alignment, verifying master cylinder pressure, and ensuring sensors and electronic modules function correctly.

Power stop brakes are a critical safety feature in modern vehicles, ensuring precise stopping control. However, issues with these advanced braking systems can arise due to various factors. This comprehensive guide delves into understanding the functionality of power stop brakes, exploring common problems like pulsating or soft brakes, and providing detailed troubleshooting steps for effective DIY repairs or professional intervention. By the end, you’ll be equipped to navigate any power stop brake challenges.

- Understanding Power Stop Brake Functionality

- Common Issues and Their Causes

- Troubleshooting Steps for Effective Repair

Understanding Power Stop Brake Functionality

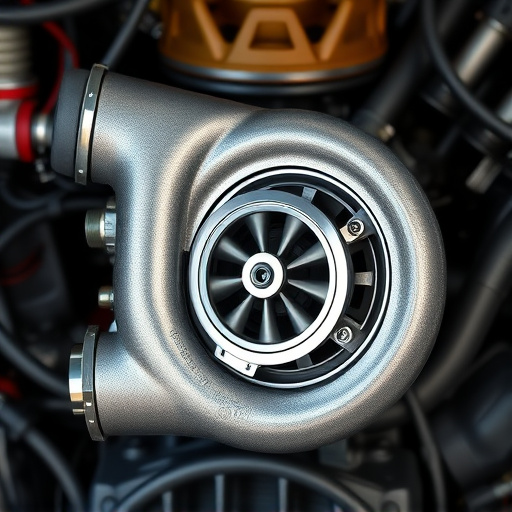

Power Stop brakes are a modern automotive innovation designed to enhance braking performance and provide better control during stopping. Unlike traditional brakes that rely solely on friction between pads and rotors, Power Stop systems incorporate advanced engineering to deliver increased stopping power and reduced fade. This is achieved by utilizing specialized materials and designs within the brake pads and rotors, allowing for more efficient heat dissipation and consistent braking performance under heavy load.

The functionality of Power Stop brakes is closely tied to their ability to optimize airflow and reduce heat buildup. Many high-performance vehicles, equipped with features like cold air intakes and muffler tips, can benefit from this technology. By improving the flow of cool air to the brakes, Power Stop brakes can maintain their effectiveness even during intense driving conditions. Additionally, well-maintained suspension components play a crucial role in ensuring proper brake alignment and contact point, further enhancing the overall braking experience.

Common Issues and Their Causes

Power stop brakes are designed to provide precise control and enhanced stopping power, but like any mechanical system, they’re not immune to issues. Common problems can range from reduced braking efficiency to strange noises during application. One frequent cause is contaminated or worn brake fluid, which can lead to inconsistent pedal response and decreased brake performance. This is especially true in vehicles with performance exhaust systems, where increased heat and moisture can accelerate fluid degradation.

Another typical issue involves the brake pads themselves. Worn or thin pads can result in prolonged braking distances and increased pressure on other components, potentially leading to warped rotors. These problems are often exacerbated by driving conditions, such as aggressive braking or operating in environments with varying temperatures. Maintaining proper maintenance schedules, including regular fluid checks and timely pad replacement, is crucial for ensuring optimal power stop brake performance and extending the lifespan of related components like exhaust mufflers.

Troubleshooting Steps for Effective Repair

When troubleshooting issues with power stop brakes, a systematic approach is key to effective repair. Start by visually inspecting the brake system for any signs of damage or wear, particularly on the pads, rotors, and calipers. Check for leaks in the hydraulic system, as well as proper alignment of the brake components. Unlikely sources like warped rotors or contaminated brake fluid can also cause performance issues with power stop brakes.

Next, verify that the braking system is receiving adequate pressure from the master cylinder. Inspect the lines and hoses for any cracks, bulges, or corrosion that could impede fluid flow. Consider checking the exhaust systems, including cat-back exhausts, as modifications in these areas can sometimes affect brake performance. Additionally, ensure that all sensors and electronic modules are functioning correctly, as they play a crucial role in modern power stop brake systems.

Power stop brakes are a critical safety feature that requires regular attention and troubleshooting. By understanding their functionality, identifying common issues like pedal pulsation or excessive heat, and following effective repair steps, vehicle owners can ensure these brakes perform optimally. Armed with this knowledge, you’re better equipped to navigate potential problems, enhancing both brake performance and overall driving safety when dealing with power stop brakes.