Hydraulic suspension systems, found in high-performance vehicles, utilize pressurized fluids for enhanced off-road capabilities and adjustable ride height. Structural reinforcement is critical to ensure these advanced systems manage increased stress from components like exhaust tips and brakes, maintaining vehicle integrity, stability, and safety on diverse terrain.

Hydraulic suspension systems offer unparalleled ride quality and control, but their performance and safety heavily rely on adequate structural reinforcement. This article delves into the intricate relationship between these advanced suspension technologies and the need for reinforced structures. We explore how understanding hydraulic suspension systems leads to recognizing the critical role of structural integrity in ensuring passenger safety. By examining specific reinforcement measures, we highlight best practices for enhancing vehicle stability and performance.

- Understanding Hydraulic Suspension Systems

- The Role of Structural Reinforcement

- Ensuring Safety Through Reinforcement Measures

Understanding Hydraulic Suspension Systems

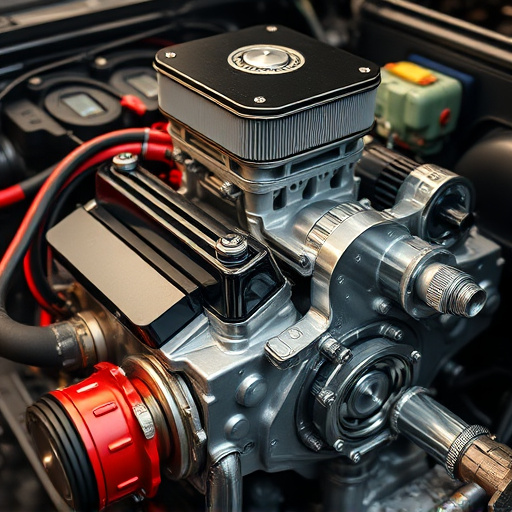

Hydraulic suspension systems are a complex network of components that work together to provide smooth and controlled movement. This advanced technology utilizes pressurized fluid to facilitate vehicle height adjustment, allowing for enhanced ground clearance and improved off-road capabilities. By enabling precise control over ride height, hydraulic suspensions offer both comfort and stability, especially on uneven terrain.

These systems are particularly prevalent in high-performance vehicles, where they contribute to the overall driving experience by offering customizable ride heights that cater to different road conditions. Furthermore, advanced hydraulic suspension setups can be fine-tuned for optimal performance brakes and muffler tips, ensuring drivers have full control over their vehicle’s behavior, especially when tackling challenging off-road courses or enjoying the twisties on a winding road.

The Role of Structural Reinforcement

Structural reinforcement plays a pivotal role in enhancing the safety and overall performance of vehicles equipped with hydraulic suspension systems. These advanced suspension mechanisms, while offering unparalleled comfort and control, place additional stress on various components, particularly during sudden movements or extreme driving conditions.

Reinforcing critical structural elements ensures that the hydraulic suspension can efficiently manage these forces without compromising integrity. This reinforcement often involves strengthening key areas such as chassis members, mounting points, and shock absorbers, which directly interact with the intricate network of brake components, intake components, and performance air filters integral to the hydraulic suspension system’s smooth operation and the vehicle’s overall stability.

Ensuring Safety Through Reinforcement Measures

In the realm of vehicle engineering, hydraulic suspension systems are renowned for their ability to offer a smooth and controlled ride. However, ensuring safety is paramount, especially when considering the dynamic nature of these suspensions. To accomplish this, structural reinforcement plays a crucial role in fortifying the vehicle’s framework against potential stresses and strains induced by the hydraulic components. This reinforcement measures act as a robust shield, safeguarding both the passengers and the integrity of the vehicle itself.

By incorporating tailored reinforcement strategies, such as reinforced brackets and stiffened chassis sections, manufacturers can mitigate risks associated with components like exhaust tips, performance air filters, and brake pads. These safety-focused enhancements are particularly vital during high-performance scenarios or extreme driving conditions where the hydraulic suspension system is subjected to intense forces. Consequently, drivers can experience enhanced stability, reduced risk of accidents, and improved overall confidence while navigating challenging terrains or engaging in dynamic driving activities.

Hydraulic suspension systems, while offering enhanced ride comfort and control, necessitate adequate structural reinforcement for optimal safety. By reinforcing key components, vehicles equipped with hydraulic suspension can navigate diverse road conditions with greater stability and reduced risk of failure. This article has explored the intricate relationship between these two elements, emphasizing the importance of structural integrity in hydraulic suspension systems to ensure a secure and enjoyable driving experience.