Proper intercooler piping bracing and securing is vital for high-performance vehicles to prevent leaks, ensure peak efficiency, and safeguard components. Target stress points, use robust brackets and hardware, distribute weight evenly, and conduct regular inspections to maintain a reliable cooling system.

Intercooler piping, a vital component in vehicle cooling systems, requires proper bracing and securing for optimal performance. This article delves into the fundamentals of intercooler piping, exploring effective bracing techniques to ensure durability under extreme conditions. We outline best practices for securing piping, offering valuable tips to prevent leaks and maintain efficient cooling. Understanding these aspects is crucial for both DIY enthusiasts and automotive professionals alike, ensuring reliable functionality over time.

- Understanding Intercooler Piping Basics

- Proper Bracing Techniques for Durability

- Securing Piping: Best Practices and Tips

Understanding Intercooler Piping Basics

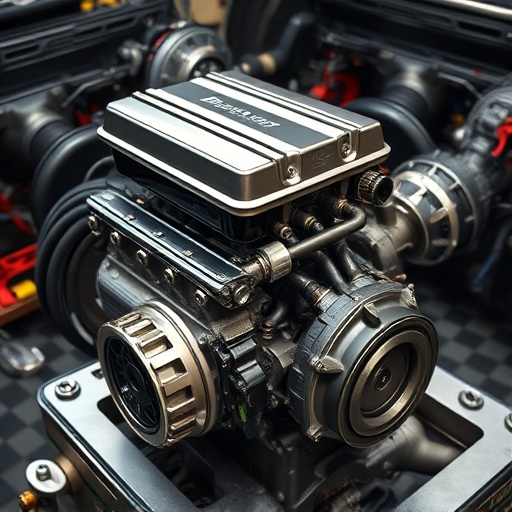

The intercooler, a vital component in many high-performance vehicles, plays a crucial role in maintaining optimal engine temperature. It’s designed to lower the air charge temperature entering the engine, thereby enhancing vehicle performance and efficiency. Understanding intercooler piping basics is essential for any car enthusiast looking to optimize their vehicle’s capabilities.

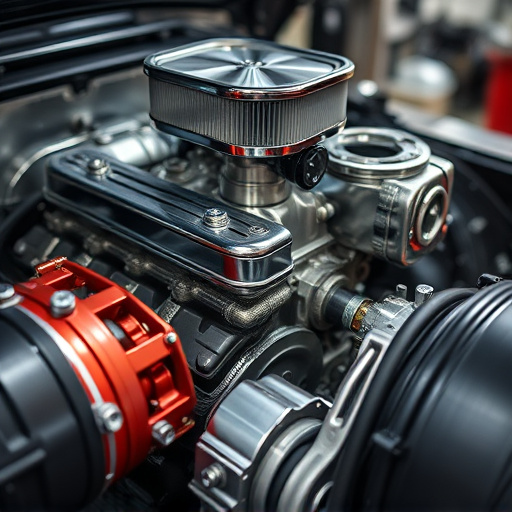

Intercooler piping refers to the network of tubes that connect the intercooler to the engine’s intake system. These pipes are responsible for transporting hot air away from the intercooler, allowing cool air to enter the engine. Proper bracing and securing of these pipes is critical. Poor installation can lead to leaks, reduced performance, and even damage to other components like brake pads, especially during intense driving conditions or when using coilover kits designed to enhance vehicle handling and performance.

Proper Bracing Techniques for Durability

Proper bracing is an integral part of ensuring the longevity and reliability of intercooler piping systems. When designing or installing intercoolers, it’s crucial to consider the specific stresses and forces that the piping will encounter, especially in high-performance vehicles. Using robust and strategically placed brackets, supports, and crossmembers can significantly enhance structural integrity. These components act as performance brakes against unexpected vibrations and movements, preventing excessive wear and tear on the delicate intercooler tubing.

Additionally, ensuring proper alignment and secure attachment of suspension components can contribute to overall stability. Robust mounting hardware, such as high-strength bolts and bushings, should be utilized to create a solid foundation for the intercooler piping. Even minor misalignments or loose connections can lead to unwanted stress concentrations, compromising both performance and safety. Just like exhaust tips that direct gases away from critical components, well-braced intercooler piping ensures optimal cooling efficiency without introducing unnecessary vulnerabilities.

Securing Piping: Best Practices and Tips

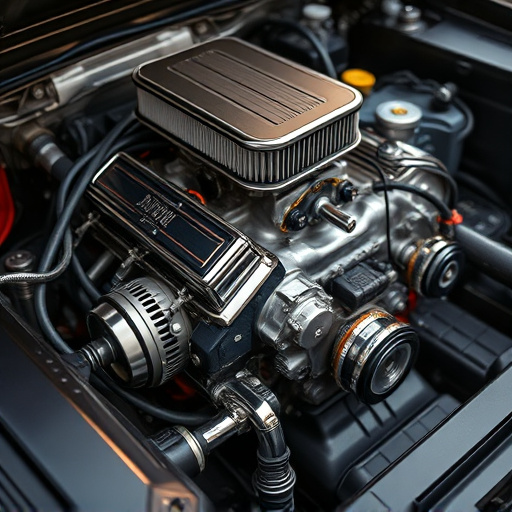

When securing intercooler piping, proper bracing is paramount to prevent leaks and ensure optimal performance. The first step involves identifying potential stress points along the pipeline, such as bends, joints, and connections to components like the radiator or engine block. Use high-quality clamps or brackets designed specifically for intercooler piping to securely fasten these areas. Ensure these brackets are properly spaced and aligned to distribute weight evenly, preventing excessive strain on any single point.

Additional tips include using corrosion-resistant hardware to guard against rust and deterioration over time. Consider incorporating coilover kits for enhanced stability, especially in vehicles with aggressive exhaust systems or muffler tips that might cause vibration. Regular inspection is also crucial; check piping for signs of damage or wear, re-tighten clamps as necessary, and replace any worn components promptly to maintain the integrity of your intercooler system.

Proper bracing and securing of intercooler piping is paramount for both performance and longevity. By understanding basic piping configurations, employing effective bracing techniques, and adhering to best practices in security, vehicle owners can ensure their intercooler systems remain efficient and reliable, enhancing overall engine performance. Regular maintenance and adherence to these guidelines are essential to prevent costly repairs and maximize the lifespan of your intercooler piping.