Regular maintenance, including timely part replacements and fluid checks, extends the lifespan of a clutch and flywheel kit, crucial for smooth power transfer in vehicles. Worn components like pressure plates and bearings should be replaced with compatible, high-quality parts to ensure optimal performance and drivetrain health, avoiding premature wear and potential damage.

“Prolonging the lifespan of your vehicle’s clutch and flywheel kit is essential for maintaining optimal performance and reducing costly repairs. This comprehensive guide delves into the mechanics of these critical components, offering insights into their functionality within your car’s drivetrain. By implementing regular maintenance routines and learning when to replace worn parts, you can significantly enhance the longevity of your clutch and flywheel kit. Discover practical tips and a step-by-step replacement guide to ensure smooth operations for years to come.”

- Understanding Clutch and Flywheel Kit Functionality

- Regular Maintenance for Longevity of Clutch Components

- Replacing Wear Parts: A Step-by-Step Guide

Understanding Clutch and Flywheel Kit Functionality

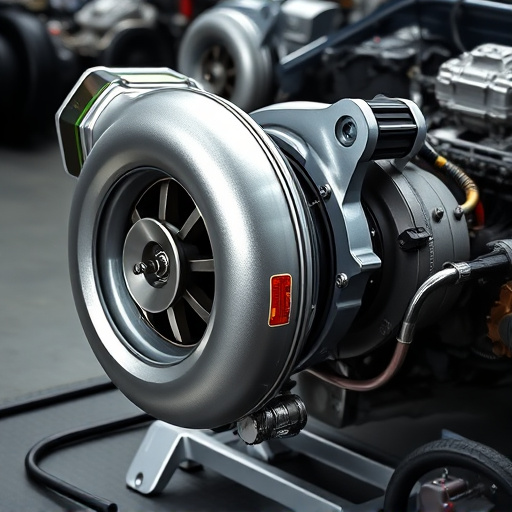

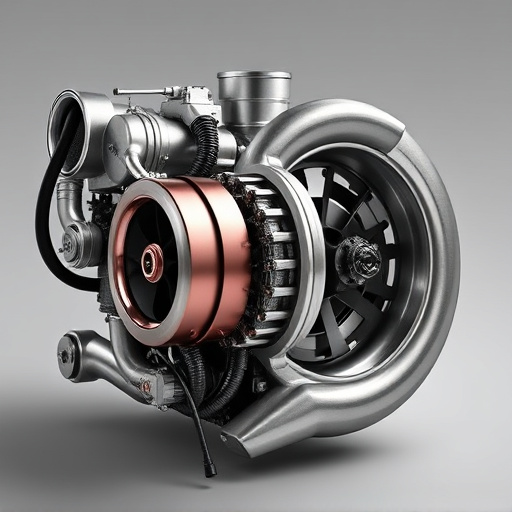

The clutch and flywheel kit is a critical component in any vehicle’s transmission system. It facilitates the transfer of power from the engine to the wheels, enabling smooth acceleration and control. The clutch, working in tandem with the flywheel, disengages the engine from the drivetrain, allowing for gear changes and slowing down without causing stress on the engine. This kit plays a vital role in ensuring efficient power transmission, enhancing both vehicle performance and driver comfort.

Understanding how these components interact is key to extending their lifespan. The flywheel acts as a rotating mass that stores energy, while the clutch allows for selective engagement or disengagement with the flywheel. Regular maintenance, including timely replacements of wear items like brake rotors, and keeping intake components clean, alongside proper installation practices, can significantly extend the life of your clutch and flywheel kit. In contrast to exhaust mufflers, which are subject to noise and pollution concerns, a well-maintained clutch system contributes to the overall longevity of your vehicle’s drivetrain.

Regular Maintenance for Longevity of Clutch Components

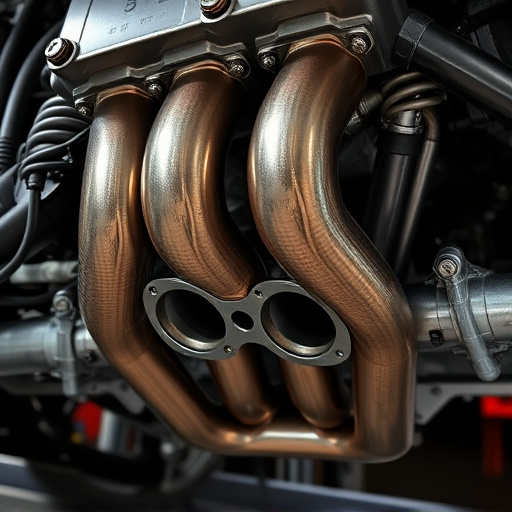

Regular maintenance plays a pivotal role in extending the lifespan of your clutch and flywheel kit. This includes keeping an eye on fluid levels—ensuring your hydraulic and clutch fluids remain at optimal levels, as low levels can lead to premature wear. Additionally, inspecting for any signs of leaks or damage is crucial; regular checks can help catch issues early, preventing more severe problems.

Beyond fluid maintenance, ensuring proper installation and timely replacements of wearable parts like brake components (including brake rotors) and cold air intakes are essential. Regularly replacing these parts as recommended by the manufacturer will safeguard your clutch and flywheel kit from excessive wear and tear, contributing to its overall longevity.

Replacing Wear Parts: A Step-by-Step Guide

When considering how to extend the lifespan of your clutch and flywheel kit, one of the most direct strategies is replacing worn parts. This process involves a few key steps that, when followed diligently, can significantly prolong the life of your vehicle’s crucial transmission components.

First, inspect all wear parts, including pressure plates, clutch discs, and flywheel bearings. Replace any damaged or excessively worn items immediately. Next, ensure compatibility with your specific make and model by checking part numbers and specifications. When selecting replacements, prioritize high-quality, reputable brands known for their durability. Additionally, consider upgrading to performance-oriented components, such as lightweight flywheels, if your budget allows. Remember that even seemingly minor upgrades can positively impact overall drivetrain efficiency.

Extending the lifespan of your vehicle’s clutch and flywheel kit is achievable through regular maintenance and timely replacement of wear parts. By understanding these components’ crucial roles in power transmission, implementing a robust maintenance routine, and following a step-by-step guide for replacements, you can significantly enhance their durability. This proactive approach ensures your vehicle’s smooth operation, reduces unexpected breakdowns, and optimizes performance over the long term.