Exhaust system shops face rust and corrosion challenges due to weather exposure, acidic gases, and part movement. Preventive measures like high-performance air filters and regular inspections ensure longer repairs, better engine performance, and higher customer satisfaction. Effective rust prevention involves maintenance checks, immediate repairs, understanding local climate, robust cleaning routines, protective coatings, prompt component replacements, and advanced welding techniques to maintain optimal vehicle performance and prolong parts lifespan.

In the world of automotive maintenance, exhaust system shops face a common challenge: tackling rust and corrosion. This intricate issue not only affects performance but also poses safety hazards. Understanding the underlying causes is key to effective prevention and repair. This article explores the common pitfalls that lead to rust buildup in exhaust systems and provides insights into best practices for exhaust system shops to combat this persistent problem, ensuring longevity and safety for all vehicles serviced.

- Understanding Rust and Corrosion in Exhaust Systems

- Common Causes of Rust Buildup in Exhaust Shops

- Effective Prevention and Repair Strategies for Exhaust Shops

Understanding Rust and Corrosion in Exhaust Systems

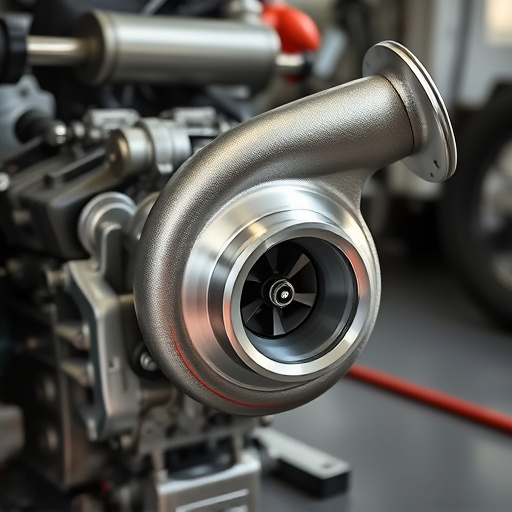

Rust and corrosion are common issues that exhaust system shops often encounter when repairing and maintaining vehicle emissions components. These problems can arise due to several factors, including exposure to varying weather conditions, acidic gases from fuel combustion, and the constant movement of parts within the exhaust system. Over time, these elements contribute to the deterioration of metal surfaces, creating weak spots that weaken the overall structural integrity of the exhaust system.

Exhaust system shops employ various strategies to combat rust and corrosion, focusing on both preventive maintenance and repair solutions. One effective method is using high-quality performance air filters, which not only enhance engine efficiency but also reduce the amount of corrosive particles entering the exhaust system. Additionally, regular inspections and timely replacements of exhaust tips and muffler tips can significantly minimize damage caused by rust and corrosion. By staying proactive in these areas, exhaust system shops can ensure longer-lasting repairs and better performance for their customers’ vehicles.

Common Causes of Rust Buildup in Exhaust Shops

Rust buildup in exhaust system shops is a common issue that can significantly impact vehicle performance and overall integrity. Several factors contribute to this problem, with many stemming from the shop’s environment and operations. One of the primary causes is moisture infiltration, as even minor water seepage into the exhaust system can catalyze rust formation over time. This is especially true for shops located in humid regions or those with inadequate drainage systems, allowing water to pool around the exhaust components.

Additionally, the proximity to harsh chemicals used for cleaning and maintenance plays a role. Many exhaust shops employ strong solvents for degreasing and surface treatments, which, if not handled properly, can accelerate corrosion. For instance, improper storage of these chemicals or inadequate ventilation might result in their evaporation, leaving behind corrosive residues that attack metal surfaces, including the exhaust system. Furthermore, the high-temperature environments in which these components operate create ideal conditions for rust to develop and spread, underscoring the need for regular maintenance and protective measures within exhaust system shops.

Effective Prevention and Repair Strategies for Exhaust Shops

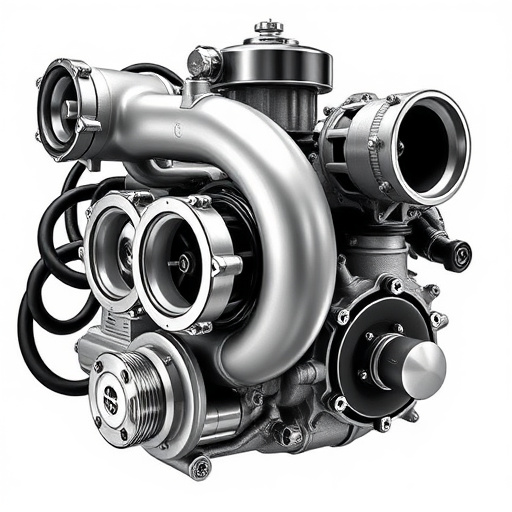

In an exhaust system shop, effective rust and corrosion prevention is paramount to maintaining vehicle performance and extending the lifespan of high-performance parts. A multifaceted approach is essential, encompassing regular maintenance checks, immediate repair of any signs of damage or leaks, and a thorough understanding of the local climate and environmental factors that contribute to corrosion. Exhaust shops should implement robust cleaning routines using specialized chemicals to remove salt, grease, and other contaminants that accelerate rust formation.

Additionally, applying protective coatings, such as high-quality rust preventatives and undercoatings, can significantly delay the onset of corrosion. Beyond prevention, exhaust system shops must possess advanced repair strategies. This includes replacing worn-out components like brake pads and air filter kits promptly to avoid prolonging exposure to corrosive elements. For existing rust or corrosion damage, professional welding techniques, coupled with specialized metal restoration treatments, can restore structural integrity and aesthetic appeal, ensuring vehicles return to peak performance.

Exhaust system shops play a vital role in maintaining vehicle health by addressing rust and corrosion, which are common adversaries. By understanding the root causes—from moisture exposure to poor ventilation—shops can implement effective strategies. These include regular inspections, applying protective coatings, and utilizing quality materials for repairs. Investing in these methods not only ensures long-lasting results but also safeguards the integrity of exhaust systems, ultimately contributing to safer and more efficient vehicle performance. For exhaust system shops, staying proactive against rust is a key step towards delivering top-notch services.