Charge pipes, made from advanced materials like lightweight alloys and high-temp polymers, optimize airflow in turbocharged engines. Their intricate designs minimize turbulence, pressure drop, and backpressure, enhancing intake, combustion, and exhaust flows. This holistic integration with exhaust tips and intake systems significantly improves engine performance, responsiveness, and fuel efficiency. Upgrading charge pipes alongside coilover kits can lead to noticeable performance gains.

“Unleashing the full potential of turbocharged engines relies heavily on understanding the role of charge pipes. These components, integral to forced induction systems, play a pivotal role in delivering air to the engine, thereby enhancing performance. This article delves into the science behind charge pipes, exploring how material choices and design innovations directly influence efficiency, power output, and turbocharged engine response times. By optimizing airflow, charge pipes become the unsung heroes, pushing turbocharged engines to new heights.”

- Understanding Charge Pipes: Their Role in Engine Performance

- How Material and Design Impact Efficiency and Power

- Optimizing Flow: Effects on Turbocharged Engine Response Time

Understanding Charge Pipes: Their Role in Engine Performance

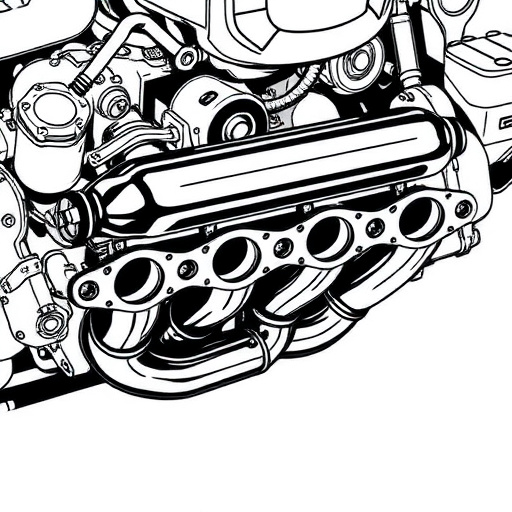

Charge pipes, integral components of turbocharged engines, play a pivotal role in enhancing performance. These pipelines are responsible for transporting compressed air from the turbocharger to the engine’s intake system, ensuring a consistent and efficient supply of boosted air. By optimizing airflow, charge pipes contribute significantly to an engine’s power output and responsiveness.

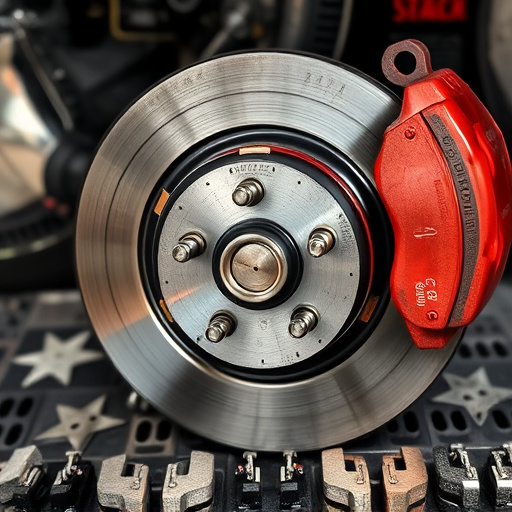

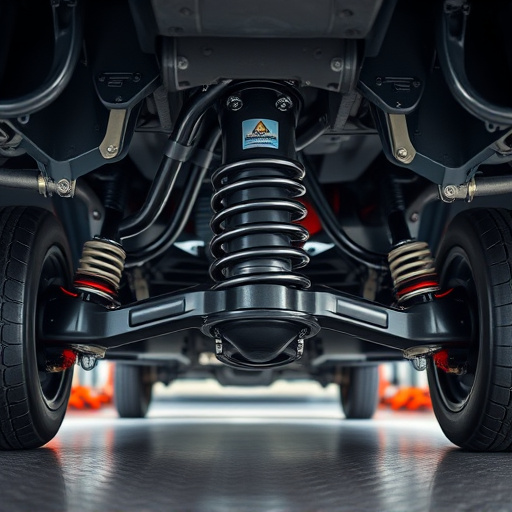

In conjunction with well-designed air intake systems and muffler tips, charge pipes form a crucial link in the performance chain. They can influence not only the overall efficiency of the turbocharger but also how quickly and effectively the engine utilizes the compressed air. Upgrading or modifying these components, often alongside coilover kits, can lead to noticeable improvements in turbocharged engines’ performance and driving experience.

How Material and Design Impact Efficiency and Power

The material and design of charge pipes play a pivotal role in enhancing the performance of turbocharged engines. Advanced materials like lightweight alloys and high-temp polymers offer significant advantages. These materials are chosen for their ability to withstand extreme temperatures and pressures, ensuring efficient gas flow. Charge pipes designed with intricate geometries and optimized shapes can reduce turbulence, minimize pressure drop, and improve overall efficiency. This, in turn, allows for better air intake, combustion, and exhaust, resulting in increased power output.

Furthermore, the integration of these charge pipes with other critical components like exhaust tips and intake components is essential. Well-designed systems ensure seamless flow, reducing backpressure and optimizing engine breathing. The strategic use of materials also contributes to overall vehicle weight reduction, enhancing performance and fuel efficiency. This interplay between design, material science, and system integration underscores the significance of charge pipes in maximizing turbocharged engine potential.

Optimizing Flow: Effects on Turbocharged Engine Response Time

Optimizing flow through charge pipes is a key factor in enhancing the response time of turbocharged engines. These pipes, designed to deliver compressed air efficiently to the engine, play a crucial role in ensuring that the turbocharger operates at its peak performance. By streamlining the airflow, charge pipes minimize restrictions and optimize the turboshaft speed, leading to faster turbine rotation and improved boost pressure. This direct correlation between efficient charging and engine responsiveness is particularly noticeable during sudden acceleration or high-load conditions.

Moreover, the integration of well-designed charge pipes with other components like exhaust mufflers and exhaust systems can further enhance overall engine performance. As air flows seamlessly through these pathways, it reduces backpressure, allowing for better combustion and more effective energy conversion. This synchronization between the charge pipes, exhaust systems, and even suspension components contributes to a smoother power delivery, resulting in an improved driving experience.

Charge pipes play a pivotal role in optimizing turbocharged engine performance. By understanding the interplay between material, design, and flow dynamics, engineers can fine-tune these components to enhance efficiency and power output. This knowledge ensures that modern engines respond swiftly and effectively, pushing the boundaries of automotive excellence while prioritizing reliability and sustainability.