DTF Adhesive Powder is a versatile material for digital printing and transfer, offering exceptional adhesive properties with heat or chemical activation. Compatible with cold and hot peel films, it enables seamless transfers onto various surfaces like wood, metal, glass, and fabric, producing crisp, long-lasting prints ideal for crafting, signage, and clothing design projects, as well as professional heat press operations.

“Discover the versatile power of DTF Adhesive Powder, a game-changer in industrial applications. This innovative product seamlessly works with both cold and hot peel films, offering unparalleled adhesion and efficiency.

In this comprehensive guide, we’ll explore the fundamentals of DTF adhesive technology, its diverse applications, and the unique advantages it brings. From manufacturing to packaging, understand why DTF powder is a must-have for any industry seeking precise, reliable bonding solutions.”

- Understanding DTF Adhesive Powder Basics

- Applications: Cold and Hot Peel Films

- Advantages & Considerations for Use

Understanding DTF Adhesive Powder Basics

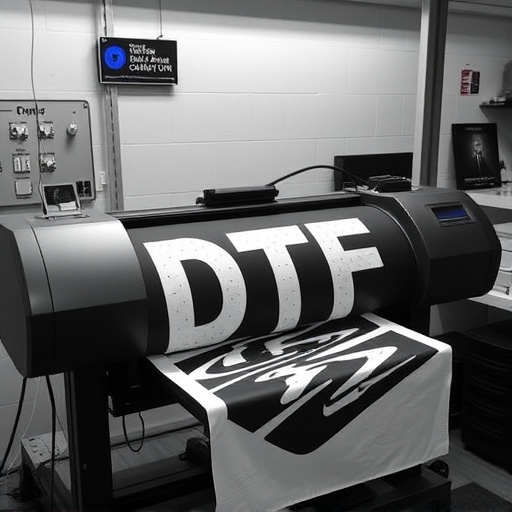

DTF Adhesive Powder is a versatile material that plays a pivotal role in the world of digital printing and transfer processes. This innovative product is designed to facilitate the creation of intricate designs on various surfaces, making it a favorite among professionals and hobbyists alike. The powder itself is a fine substance, typically made from high-quality resins, which provides exceptional adhesive properties when activated by heat or specific chemical solutions.

When used in conjunction with cold and hot peel films, DTF Adhesive Powder offers a seamless transfer process. It’s particularly useful for creating detailed dtf prints on materials like wood, metal, glass, and even fabric. The powder adheres to the substrate, forming a strong bond that can withstand various environmental conditions. This makes it ideal for crafting, signage, and even clothing design, where precise and long-lasting dtf transfer sheets are required. Heat press machines often utilize this adhesive powder to achieve crisp, clear prints, ensuring a professional finish.

Applications: Cold and Hot Peel Films

The DTF Adhesive Powder is a versatile solution for various printing and crafting projects. One of its key applications lies in the realm of cold and hot peel films, which have become indispensable in the custom t-shirt industry. This innovative powder allows for precise adhesion when applied to heat-sensitive materials, enabling the creation of intricate designs on a variety of surfaces. Whether it’s for short-run productions or small-scale DIY projects, DTF Adhesive Powder offers a simple and efficient method to achieve professional results with cold peel dtf transfers.

For those seeking the best DTF printer, this adhesive powder serves as an ideal companion. Its compatibility with both cold and hot peel films makes it a versatile choice for printers looking to expand their capabilities. By harnessing the power of this fine powder, creators can effortlessly produce high-quality graphics and patterns on textiles, paper, and other materials, opening up endless possibilities for artistic expression and personalized merchandise.

Advantages & Considerations for Use

The DTF Adhesive Powder is a versatile and powerful tool in the world of textile printing and design. One of its key advantages lies in its compatibility with both cold and hot peel films, allowing for a broader range of application methods. This feature is particularly beneficial for businesses offering custom sheets for heat pressing designs onto garments, as it offers flexibility in production processes. By accommodating different temperature requirements, this adhesive powder streamlines the printing process, making it more efficient and accessible.

When considering its use, especially with dtf transfer film and dtf printer applications, users should be aware of its potential benefits in terms of durability and precision. The adhesive’s strength ensures long-lasting designs on various fabrics, from cotton to synthetic materials. However, like any printing method, proper preparation of the substrate and design files is crucial for optimal results, ensuring the vibrant and crisp transfer of images onto garments or other fabric items.

DTF Adhesive Powder offers a versatile solution for various applications, particularly in the field of packaging. Its ability to work with both cold and hot peel films is a significant advantage, allowing for efficient production processes. By understanding the basics and considerations, manufacturers can leverage DTF adhesive powder’s potential to enhance product quality and speed, making it a valuable asset in modern industry standards.