DTF Technology has revolutionized print-on-demand by replacing traditional printing methods with direct fabric application using advanced digital techniques. This innovation offers precision, fast results, and vibrant prints on dark fabrics, appealing to startups and large manufacturers alike. DTF boosts productivity, streamlines custom design creation, and expands product options, especially for high-quality graphic tees and personalized hoodies, transforming the industry and opening new business opportunities.

The latest advancements in Direct to Fabric (DTF) technology are transforming print-on-demand platforms, unlocking new creative possibilities. This innovative approach streamlines production processes, enabling faster turnaround times and enhanced efficiency. With DTF, customization reaches unprecedented heights, allowing businesses to offer personalized designs with vibrant, high-quality prints on a wide range of fabrics. Discover how DTF Technology is revolutionizing the industry and what it means for future printing solutions.

- Unlocking New Possibilities: DTF Revolutionizes Print-On-Demand

- Enhancing Efficiency: Streamlining Production with DTF Technology

- Customization Deepened: DTF Enables Personalized Designs

Unlocking New Possibilities: DTF Revolutionizes Print-On-Demand

The emergence of DTF (Direct-to-Fabric) technology has unlocked a new era in the print-on-demand industry, revolutionizing the way custom garments and products are created. This innovative process eliminates the need for traditional printing methods, such as screen printing or heat transfer, by directly applying ink to the fabric using advanced digital techniques. With DTF, businesses can now offer an expanded range of options for customers seeking unique, personalized items.

DTF printing for dark fabrics has been a game-changer, enabling the production of high-quality custom graphic tees and apparel with vibrant, long-lasting prints. The technology’s precision allows for intricate designs and detailed images, ensuring that every tee becomes a canvas for artistic expression. Moreover, it offers an efficient and cost-effective solution for businesses aiming to cater to the growing demand for personalized dtf for Custom graphic tees, appealing to both small startups and large-scale manufacturers. Understanding the dtf meaning behind this technology is key to recognizing its potential in transforming the way we approach custom printing.

Enhancing Efficiency: Streamlining Production with DTF Technology

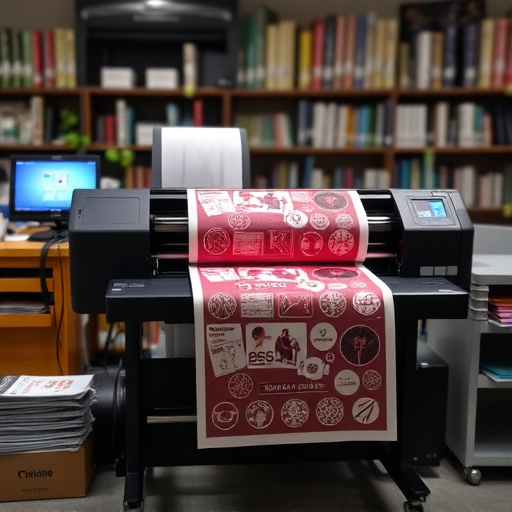

DTF Technology has revolutionized print-on-demand platforms by significantly enhancing efficiency in production processes. With its advanced capabilities, DTF offers a streamlined approach to creating custom designs and prints. This technology eliminates the need for traditional screen printing methods, thereby simplifying the entire workflow. By directly applying inks to specific areas of a substrate using a digital process, DTF transfers ensure precise and fast results, reducing time and labor costs.

One of the key advantages is the versatility it brings to the table, especially when compared to cold peel dtf transfers or traditional heat transfer paper. DTF heat transfer paper allows for intricate and detailed prints, making it suitable for a wide array of products. This innovation not only boosts productivity but also opens up new opportunities for businesses to cater to diverse customer demands with ease, resulting in more efficient and profitable operations.

Customization Deepened: DTF Enables Personalized Designs

The advent of Direct-to-Film (DTF) Technology has significantly deepened the customization options available on print-on-demand platforms. This innovative approach allows for personalized designs to be directly applied to various products, including popular items like direct to film personalized hoodies. DTF offers a level of flexibility and precision that traditional printing methods struggle to match, enabling businesses to cater to individual customer preferences with ease.

With DTF for Apparel, creating unique, on-trend pieces is more accessible than ever. The technology ensures that designs are vibrant, detailed, and durable, making it the best DTF printer option for those seeking high-quality output. Whether it’s a custom hoodie, t-shirt, or any other apparel item, DTF Technology empowers creators and businesses to stand out in a crowded market by offering personalized products with speed and efficiency.

The implementation of DTF (Direct to Fabric) technology in print-on-demand platforms marks a significant leap forward, offering enhanced efficiency, deeper customization, and new creative possibilities. By streamlining production processes, DTF Technology ensures faster turnaround times without compromising quality, catering to the demands of modern consumers who value both speed and personalization. As this innovative technology continues to evolve, it promises to revolutionize the print-on-demand industry, providing businesses and designers with even more opportunities to create unique, personalized products.