Long tube headers, featuring intricate mandrel bends, are essential automotive upgrades that significantly enhance performance and efficiency. Their unique design reduces restrictions and turbulence in gas flow, leading to better combustion, improved cylinder breathing, and more powerful engines. These headers, crafted with durable materials using advanced manufacturing techniques, offer precise control over gas mixing and heat distribution, making them ideal for high-performance vehicles and racing teams. By optimizing airflow, long tube headers deliver increased speed and acceleration while ensuring longevity, even under intense conditions.

Long tube headers with mandrel bends are a game-changer in fluid flow technology. This article delves into the intricate world of these components, exploring their role and benefits in enhancing overall system performance. We’ll uncover the science behind mandrel bends, why they’re crucial for smooth flow, and delve into diverse applications where long tube headers excel. Get ready to discover how these innovations are revolutionizing various industries.

- Understanding Long Tube Headers: Their Role and Benefits

- The Science Behind Mandrel Bends: Enhancing Flow Efficiency

- Applications and Advantages: Where Long Tube Headers with Mandrel Bends Shine

Understanding Long Tube Headers: Their Role and Benefits

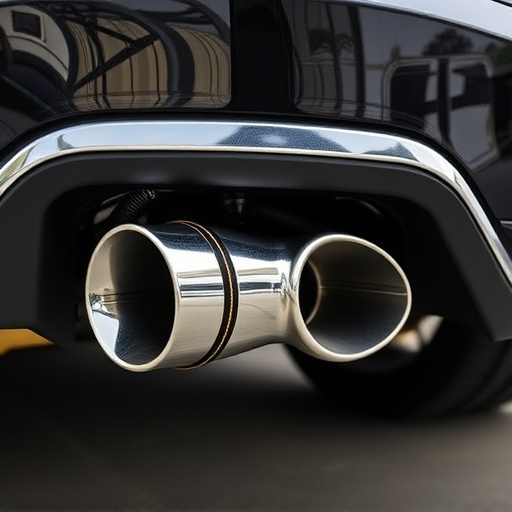

Long tube headers are a key component in many automotive systems, particularly when it comes to enhancing performance and efficiency. These specialized components are designed with a lengthy, tubular structure that connects multiple exhaust ports within an engine. Their primary role is to facilitate smooth gas flow, ensuring optimal combustion and power output. By reducing restrictions and minimizing turbulence, long tube headers allow for improved airflow, which translates to increased engine performance.

One of the significant benefits of long tube headers is their ability to enhance the overall efficiency of a vehicle’s engine. They promote better cylinder breathing, especially in high-performance vehicles with cold air intakes, resulting in more powerful and responsive brakes. This design is particularly advantageous for enthusiasts seeking to maximize their car’s potential, as it can contribute to improved acceleration and top-end speed. Moreover, the seamless construction of these headers, often featuring mandrel bends, ensures long-lasting durability, even under intense driving conditions, complementing high-performance brakes.

The Science Behind Mandrel Bends: Enhancing Flow Efficiency

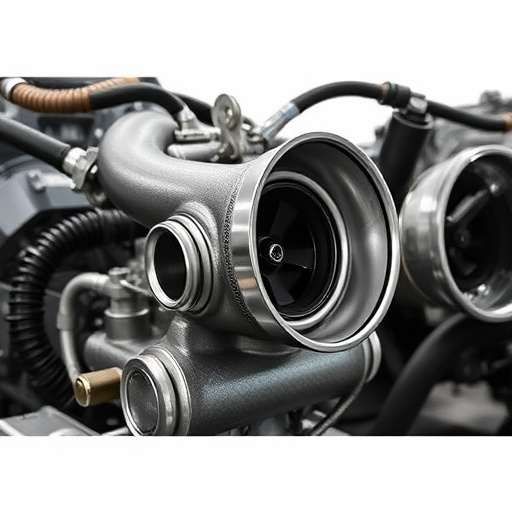

The science behind mandrel bends in long tube headers is a key factor in enhancing flow efficiency for high-performance vehicles. Mandrel bending involves shaping metal tubes using a specialized tool, creating smooth curves without adding extra thickness or weakening the material. This process allows for precise control over the radius and angle of the bend, ensuring optimal gas flow through the headers.

When integrated into long tube header designs, mandrel bends contribute to improved turbulence and gas mixing, which are vital for efficient combustion. Unlike other bending techniques, mandrel bends preserve the inner diameter of the tube, minimizing restrictions that could compromise engine performance. This is particularly beneficial in high-performance parts like custom brake components or a cat-back exhaust system, where smooth flow is crucial for maximizing power and efficiency.

Applications and Advantages: Where Long Tube Headers with Mandrel Bends Shine

Long tube headers with mandrel bends are not just components; they are game-changers in automotive engineering, particularly when it comes to enhancing performance and flow. These headers find their sweet spot in a variety of applications, from high-performance exhaust systems to custom car builds and even professional racing teams. Their design allows for smoother gas flow, which translates directly into increased engine power and efficiency.

One of the key advantages lies in their ability to manage heat distribution more effectively than stock headers. Mandrel bends create a longer path for gases to travel, reducing turbulence and allowing for better cooling. This is especially beneficial for high-revving engines where maintaining optimal operating temperatures is crucial. Moreover, long tube headers often incorporate advanced manufacturing techniques, ensuring precision fitment and durability, vital components for any automotive enthusiast considering performance upgrades like suspension kits or brake components, or seeking to optimise their vehicle’s exhaust system with a high-performance exhaust setup.

Long tube headers with mandrel bends represent a powerful combination for optimizing fluid flow in various industries. By understanding their role and benefits, as well as the science behind mandrel bend technology, it’s clear these components offer significant advantages. Their efficient design enhances performance, improves reliability, and reduces maintenance needs. Whether in automotive, industrial, or other sectors, long tube headers with mandrel bends are a game-changer for achieving smooth flow and maximizing system efficiency.