A clutch and flywheel kit is a vital manual transmission component, ensuring smooth power transfer and gear changes. When purchasing, opt for high-quality materials for durability under performance upgrades. Conduct a thorough inspection before buying, checking for damage, corrosion, cracks, play in the assembly, and quality control marks. Examine functionality, balance, and effectiveness of parts. Assess signs of wear, misalignment, and corroded surfaces to avoid subpar kits leading to performance issues and premature failure.

Before purchasing a clutch and flywheel kit, thorough inspection is crucial. This guide equips you with the knowledge to navigate the process seamlessly. Understanding the components and their functions is the first step. Next, utilize our comprehensive inspection checklist to ensure top-tier quality. We also highlight common issues to watch out for, empowering you to make informed decisions. By following these tips, you’ll secure a reliable clutch and flywheel kit that enhances your vehicle’s performance.

- Understanding Clutch and Flywheel Kit Components

- Inspection Checklist for Quality Assurance

- Common Issues to Look Out For Before Purchase

Understanding Clutch and Flywheel Kit Components

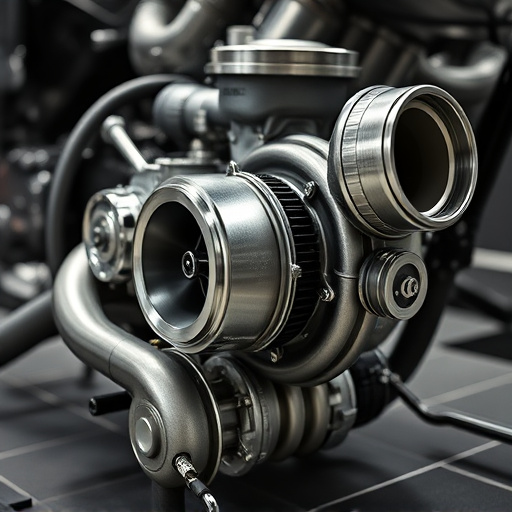

A clutch and flywheel kit is a crucial assembly that facilitates smooth power transmission in vehicles with manual transmissions. Understanding the components within the kit is essential for making informed purchasing decisions. The clutch, a vital component, engages and disengages the engine from the transmission, allowing drivers to shift gears seamlessly. It consists of a pressure plate, release bearing, and clutch disc, working together to transmit torque while enabling easy gear changes.

Complementing the clutch is the flywheel, which stores and releases rotational energy from the engine. It absorbs shock loads and helps smooth out power delivery. A worn or damaged flywheel can lead to performance issues, so checking its condition is paramount. Additionally, when considering a purchase, look for kits that include high-quality components, such as durable materials for the pressure plate and clutch disc, ensuring longevity even under demanding driving conditions, especially if you’re looking for superior performance with potential upgrades like a cat back exhaust or high-performance parts.

Inspection Checklist for Quality Assurance

Before purchasing a clutch and flywheel kit, performing a thorough inspection is crucial for ensuring quality and optimal vehicle performance. Here’s a simple checklist to guide your evaluation:

1. Visual Inspection: Examine the components for any signs of damage, corrosion, or wear. Check for cracks in the flywheel, excessive play in the clutch assembly, and ensure all parts are clean and free from debris. Look over the kit’s packaging and manual for any visible quality control marks or certifications that indicate compliance with industry standards.

2. Functionality Testing: Test the clutch pedal for smooth and precise operation. Engage the clutch and check for proper disengagement and re-engagement. Apply pressure to ensure the pedal returns to its original position without any stickiness or sponginess. Additionally, verify the flywheel’s balance by rotating it by hand; it should spin smoothly with minimal vibration. Consider testing the air filter kits (if included) for cleanability and effectiveness in capturing contaminants to maintain peak engine performance. Lastly, inspect high-performance parts for precision manufacturing, as these can significantly impact vehicle handling and acceleration.

Common Issues to Look Out For Before Purchase

Before purchasing a clutch and flywheel kit, it’s crucial to be aware of potential issues that could indicate subpar quality or impending problems. Common red flags include signs of wear, damage, or misalignment in both components. Inspect the clutch for any worn or damaged friction material, which can lead to reduced performance and increased noise. Look for excessive play or misalignment in the flywheel, as this may suggest improper installation or manufacturing defects.

Additionally, check for corrosion on metal surfaces, especially if the kit is used or has been stored for an extended period. Corrosion can compromise the integrity of the clutch and flywheel, leading to premature failure. While examining the kit, consider the overall condition of associated components like brake rotors, air filter kits, and exhaust systems, as these can offer insights into the general quality of the clutch and flywheel assembly.

When inspecting a clutch and flywheel kit, understanding its components and adhering to a thorough inspection checklist are key to ensuring quality. By being vigilant for common issues, you can make an informed decision when purchasing, guaranteeing a reliable and safe driving experience. Remember, a well-maintained clutch and flywheel kit is integral to your vehicle’s overall performance and longevity.